Multifunctional robot for drilling site

A field-used, multi-functional technology, applied to drilling equipment, drill pipes, drill pipes, etc., can solve problems such as insecurity and low automation, achieve long life, high safety, and reduce hidden dangers of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

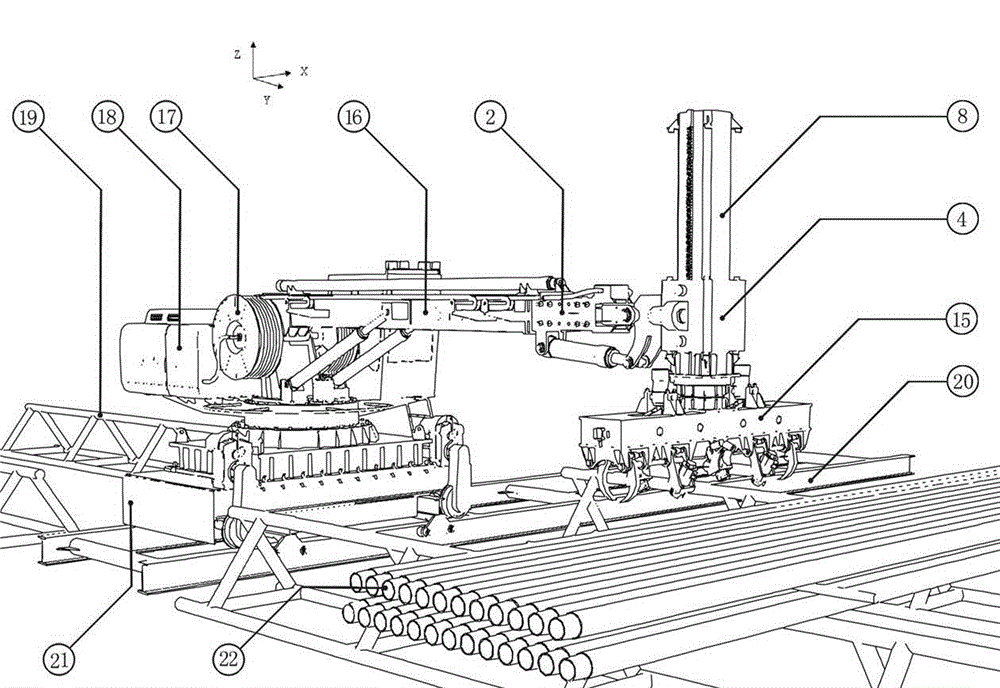

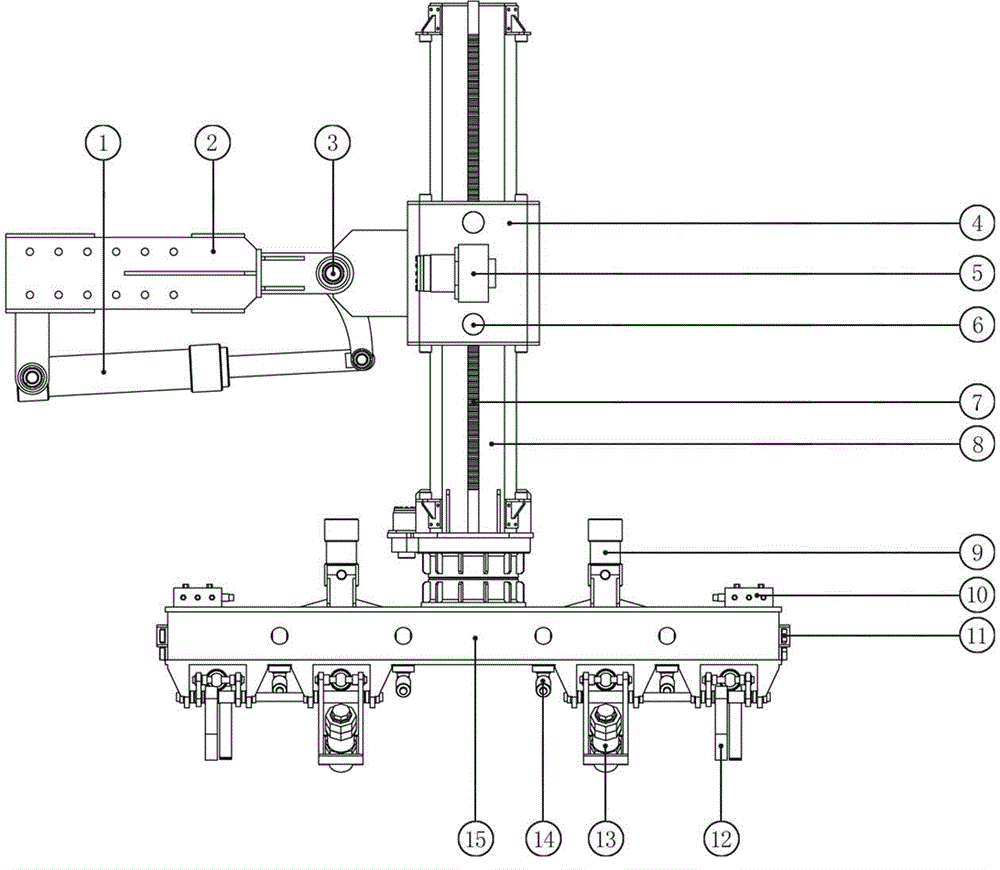

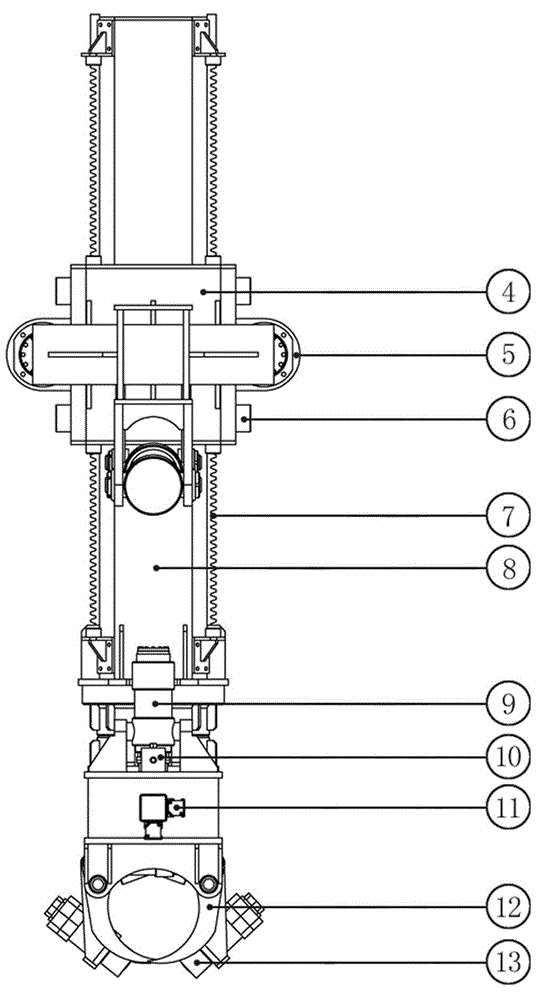

[0019] Reference attached Figure 1-4 , a kind of multifunctional robot for drilling site, including a crane 18 and an extension arm 16, the front end of the extension arm 16 is hinged with a ram cover 4 through a connecting sleeve 2, and the connecting sleeve 2 and the ram cover 4 are connected by a ram cover swing cylinder 1 and Form a rotation drive fit; the ram cover 4 is a hollow structure, the ram cover 4 is set outside the ram 8, the ram rack 7 is set on the ram 8, the ram rack 7 and the ram displacement hydraulic motor set on the ram cover 4 The speed reducer 5 and the ram rack brake 6 form a dynamic fit; the lower end of the ram 8 forms a rotational fit with the manipulator frame 15 through the turntable bearing; , Grabbing claws 12, friction wheels 13 and floating positioning rollers 14 are connected and driven by oil cylinders respectively.

[0020] Embodiment 1 is a basic embodiment of the present invention, which can complete the basic functions of grabbing, rota...

Embodiment 2

[0022] combined with Figure 1-4 , a kind of multifunctional robot for drilling site mainly consists of crane 18, walking track 20, extension arm 16, connection sleeve 2, ram cover 4, ram 8 and mechanical mobile phone frame 15 several major parts. Wherein: the connecting sleeve 2 is connected with the extension arm 16 through the standard connecting plate, and the hinge mandrel 3 and the ram cover swing cylinder 1 are installed between the ram cover 4 and the connecting cover 2 . The ram cover 4 is hollow, and is set on the outside of the ram 8, and the ram 8 forms a dynamic fit with the ram cover 4 through the ram rack 7. The end of the ram 8 is provided with a mechanical mobile phone frame 15, and the mechanical mobile phone frame 15 forms a rotation fit with the ram 8 through a turntable bearing driven by a hydraulic motor.

[0023] Four groups of evenly distributed floating positioning rollers 14 are arranged on the bottom surface of the mobile phone frame 15, each group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com