Method for estimating charge air cooler condensation storage with an intake oxygen sensor

A charge air cooling and oxygen sensor technology, which is applied in the control of coolant flow, the arrangement of the combination of cooling of the power unit, and the cooling of the engine, etc., can solve the problems of unstable combustion of the engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

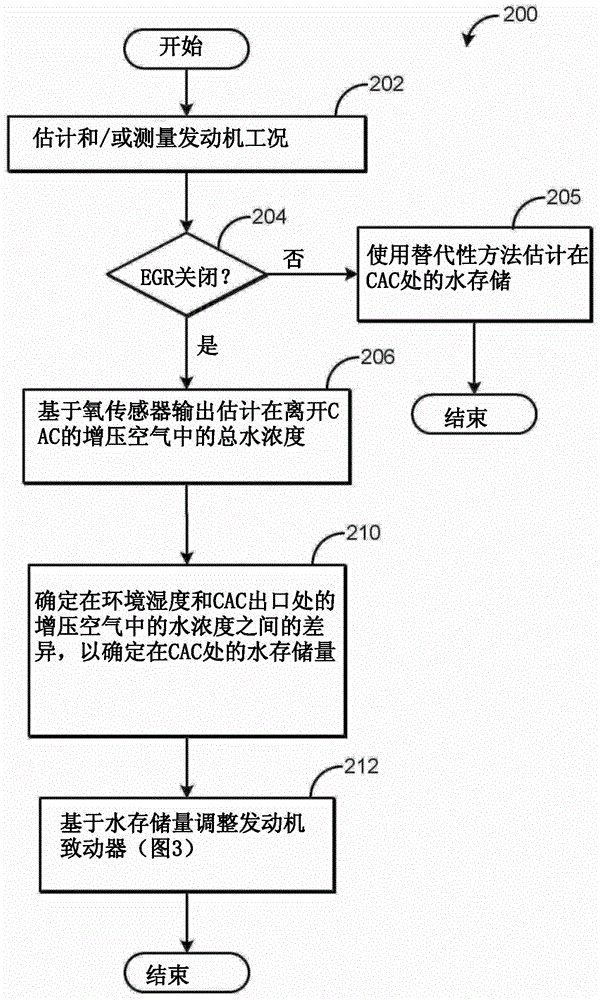

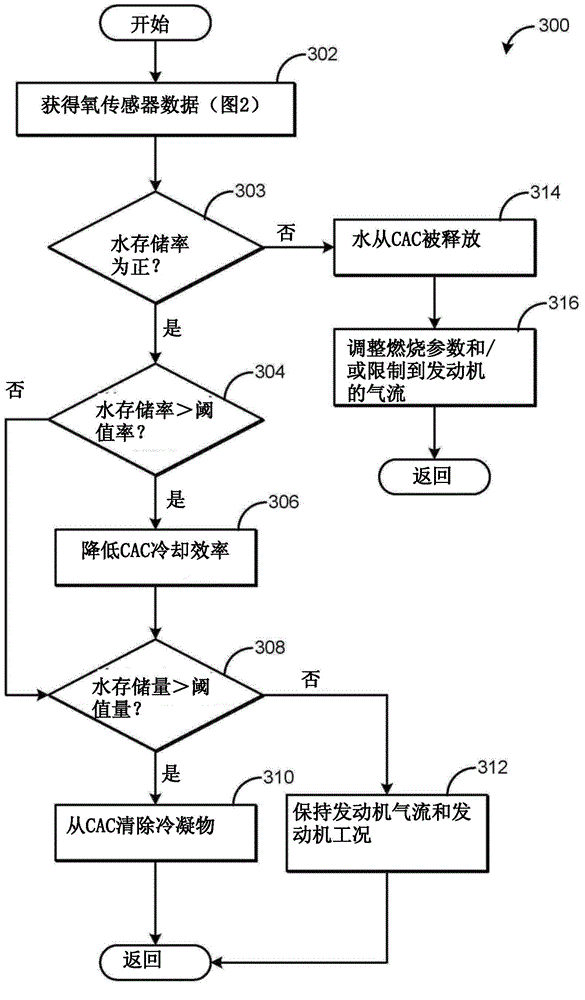

[0010] The following description refers to methods for estimating figure 1 Systems and methods for water storage in a charge air cooler (CAC) within an engine system of the system. A first oxygen sensor may be placed at the outlet of the CAC. In one example, the oxygen sensor may be a variable voltage intake oxygen sensor operable between a variable voltage (VVs) mode and a fundamental mode. figure 2 A method for operating a first oxygen sensor determining water storage at a CAC is shown. In particular, the water storage level, or the amount of water accumulated within the CAC, may be determined based on the output of the first oxygen sensor and the ambient humidity. The first oxygen sensor may be distinct from the second intake oxygen sensor placed within the intake manifold that determines EGR flow. as in image 3 As shown in , the engine controller can adjust engine operation based on the amount of water storage. Adjusting engine operation may include adjusting engine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com