Large-power LED lamp

A technology of LED lamps and high power, which is applied to lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of low heat dissipation efficiency of high-power LED lamps, and achieve the effects of light weight, simple structure and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

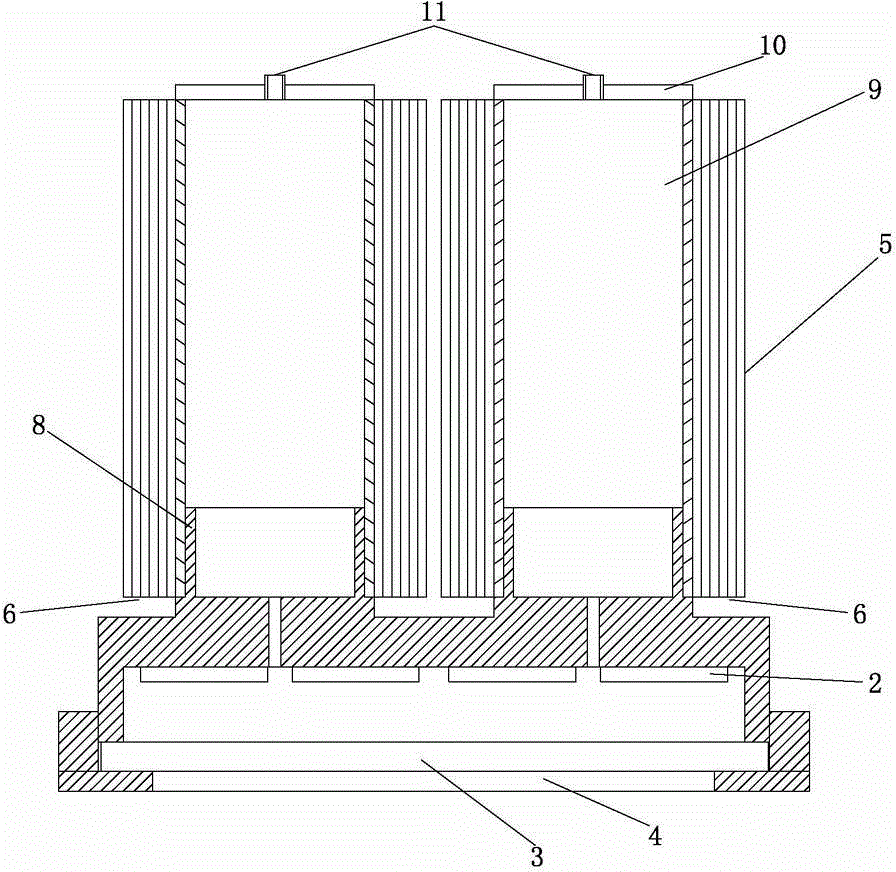

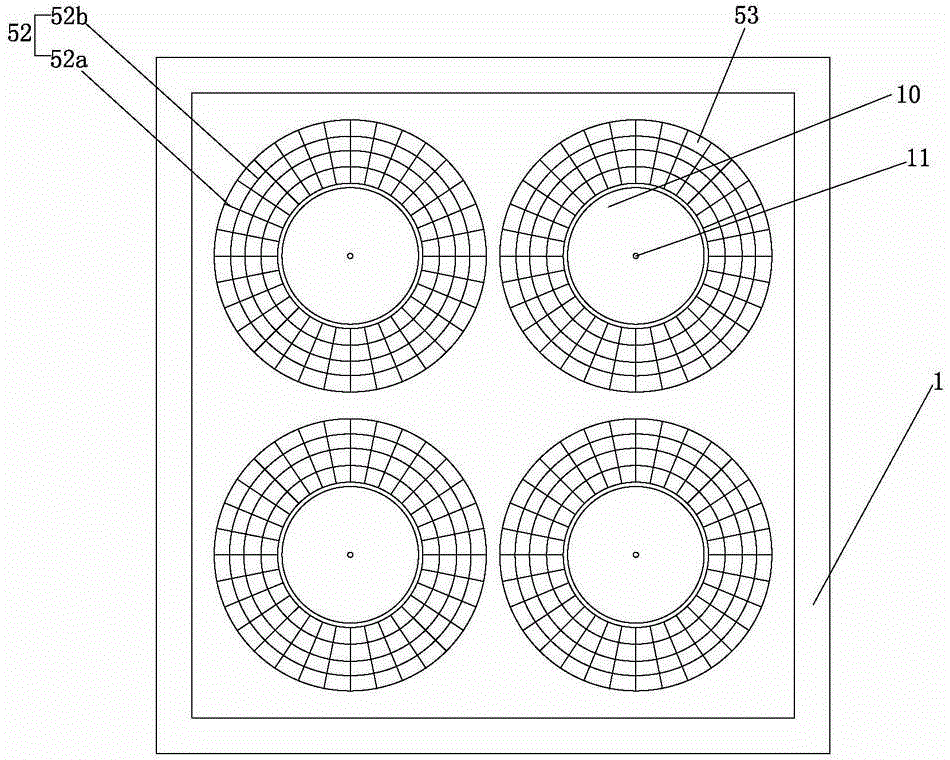

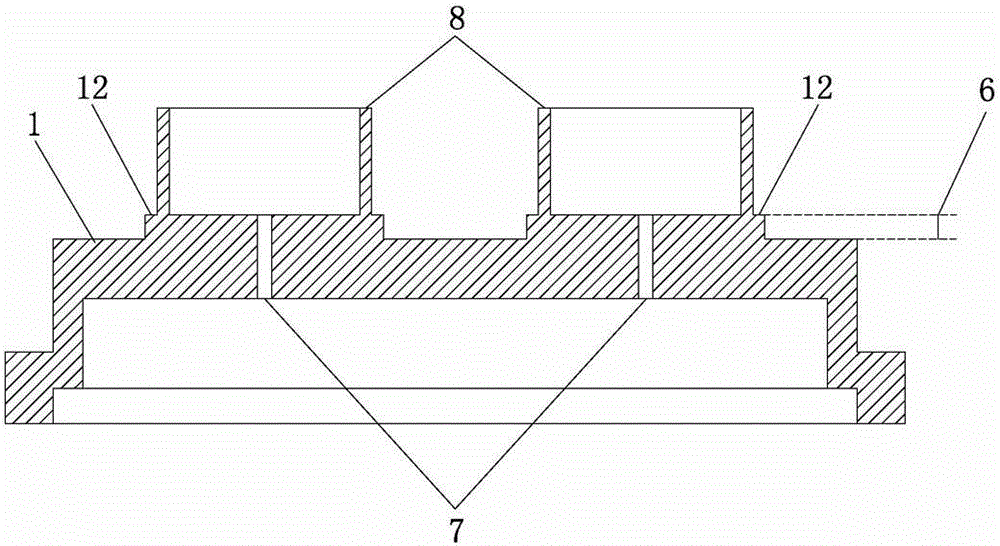

[0034] Embodiment 1 provides a high-power LED lamp, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a light source substrate 1, an LED light source 2 is mounted on one end of the light source substrate 1, and at least one heat sink 5 is fixedly connected to the other end, and the heat sink 5 includes an outer cylinder wall 51 extending vertically and located on the Inside the outer cylinder wall 51 and connected to a number of heat dissipation fins 52 on the outer cylinder wall 51, the heat dissipation fins 52 are suitable for dividing the heat sink 5 into several heat dissipation channels 53 extending in the vertical direction to dissipate heat. The top of the channel 53 is directly connected with the outside air.

[0035] Specifically, four heat sinks 5 are provided, and the heat sink 5 is formed into a hollow cylinder shape. The side of the light source substrate 1 connected to the heat sink 5 is provided with a boss 8, and the heat sink 5 Th...

Embodiment 2

[0049] This embodiment provides a high-power LED lamp, which differs from Embodiment 1 in that: Figure 5As shown, the heat dissipation fins 52 in the radiator 5 are arranged between the inner cylinder wall 54 and the outer cylinder wall 51, and are only composed of several support fins 52a, and the support fins 52a will dissipate heat The device 5 is divided into several cooling channels 53 extending in the vertical direction, that is, between any adjacent two supporting fins 52a, the inner cylinder wall 54, and the outer cylinder wall 51, a cooling channel 53 is formed in the vertical direction, and the cooling channel 53 The top of the heat dissipation channel 53 is directly connected to the outside air, and the bottom of the heat dissipation channel 53 is connected to the surface of the light source substrate 1 . The number of supporting fins 52a is determined by the power of the LED light source installed on the light source substrate 1. The greater the power of the LED l...

Embodiment 3

[0051] This embodiment provides a high-power LED lamp, which differs from Embodiment 1 in that: Figure 6 As shown, the radiator 5 includes an outer cylinder wall 51 and a plurality of heat dissipation support fins 52a radially connected between the two inner walls of the outer cylinder wall. The screw holes 14 are connected to the light source substrate 1 .

[0052] In this embodiment, the LED driving light source is hung outside the heat sink 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com