Energy-saving control method and control system of water chilling unit

An energy-saving control system and chiller technology, which is applied in heating and ventilation control systems, heating and ventilation safety systems, heating methods, etc., can solve problems such as the need to improve the energy-saving effect and the complex control process, achieve energy saving and simplify data. The effect of collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

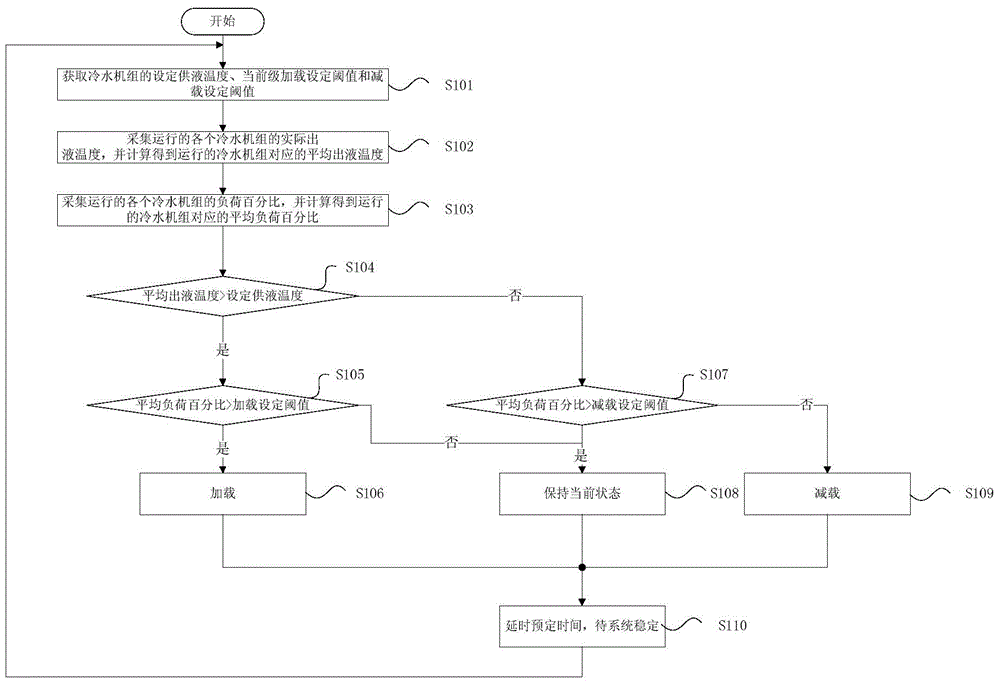

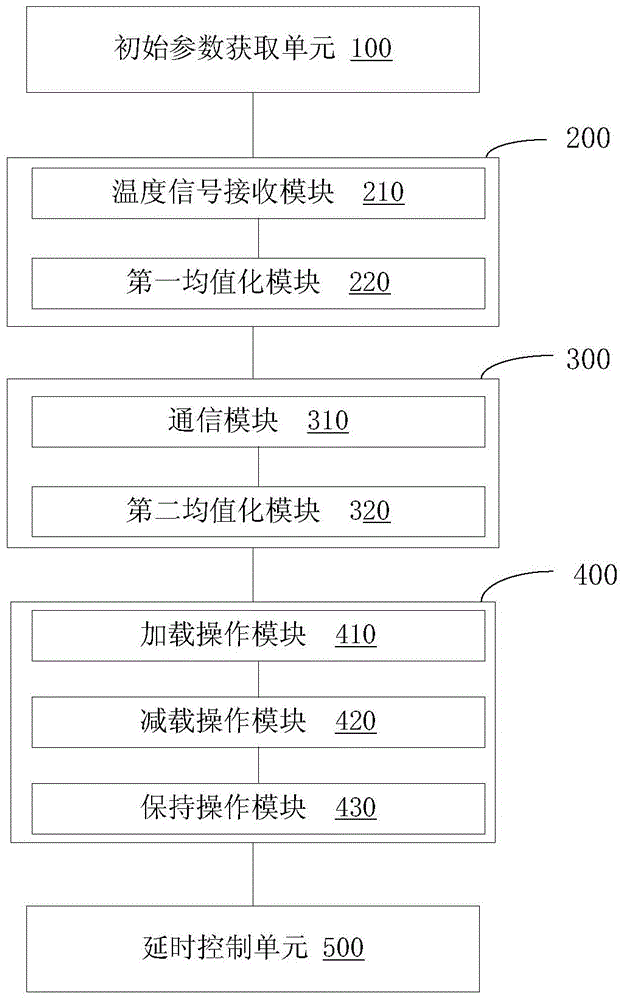

[0056] The energy-saving control method and control system of the chiller in this embodiment change the external parameters of the traditional tested chiller to calculate its cooling capacity, and compare the calculated cooling capacity with the cooling capacity of the design working condition and the actual liquid supply The temperature and the set liquid supply temperature are used to control the control strategy of the addition and subtraction of the unit. According to the performance curve of the actual operation of the chiller, the load percentage during the operation of the chiller is used as a comparison parameter. By comparing the actual The average load percentage corresponding to the running chiller and the set threshold value of loading an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com