Efficient vacuum low-temperature hot air drying device

A vacuum low temperature, hot air drying technology, applied in the direction of drying gas arrangement, drying solid materials, local agitation dryers, etc., can solve the problems of poor adaptability of items, poor drying performance, high cost of use, etc., to achieve good quality, high drying efficiency, The effect of dehumidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

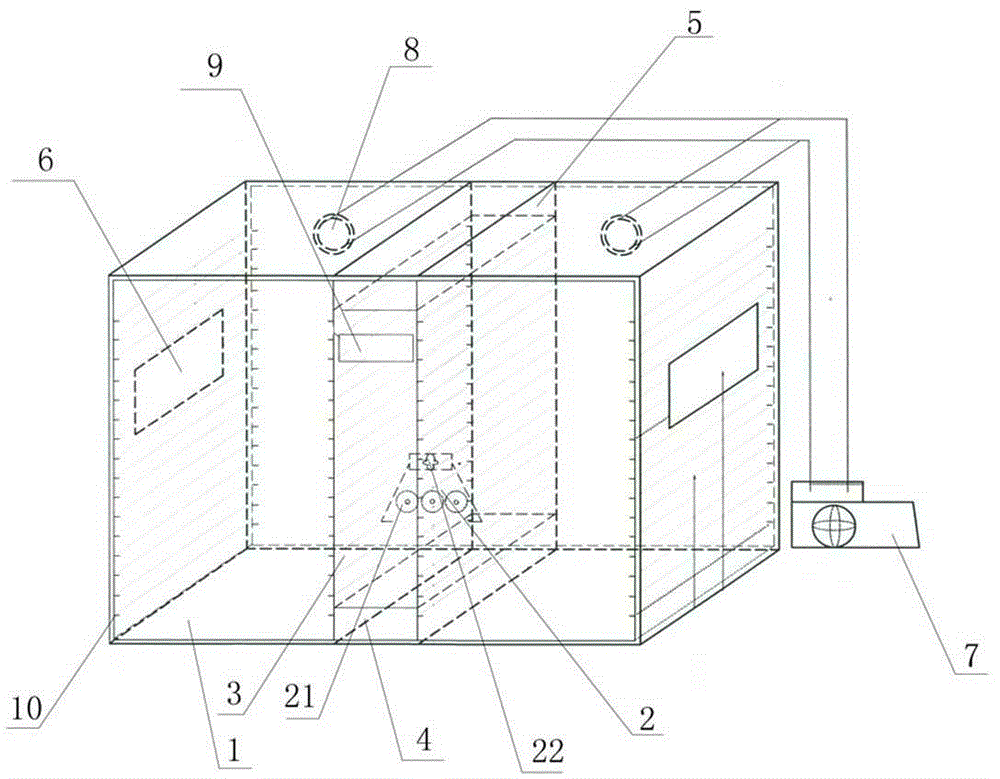

[0020] Embodiment: As shown in the figure, the present invention includes a drying box 1, which has a hot air inlet 4 and a hot air outlet 5, the hot air inlet 4 is arranged at the bottom of the drying box 1, and the hot air outlet 5 is in the drying box 1. The upper part of the hot blast inlet 4 and the hot blast outlet 5 are integrated with the hot blast generating cavity 3 or directly arranged on the hot blast generating cavity 3 .

[0021] A far-infrared heat source and a blowing device are arranged in the hot air generating cavity 3, and the upper part of the drying box 1 has a moisture discharge port 6; meanwhile, the upper part of the drying box 1 is also provided with a vacuum port 8 to connect with an external vacuum device.

[0022] Drying box 1 comprises box body, baffle plate, drying screen, and box body is made of box plate 3 of stainless steel material, forms airtight space.

[0023] The drying screen 9 has a dense mesh structure with intervals on one side, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com