Firework barrel straightening and sorting method and device

A fireworks tube and sorting technology, which is applied in the direction of pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of non-adjustable working slot distance, complicated mechanism action, and few types of plastic tubes, etc., and achieve simple and reliable device, simple and reliable mechanism, The effect of no noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

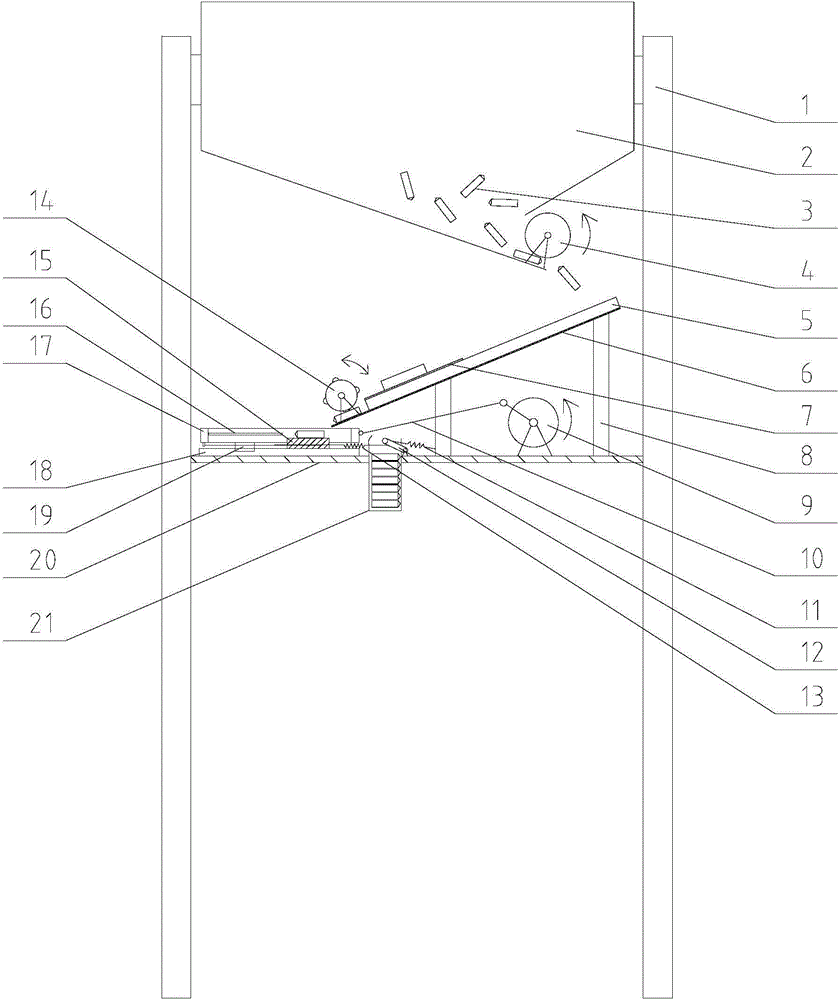

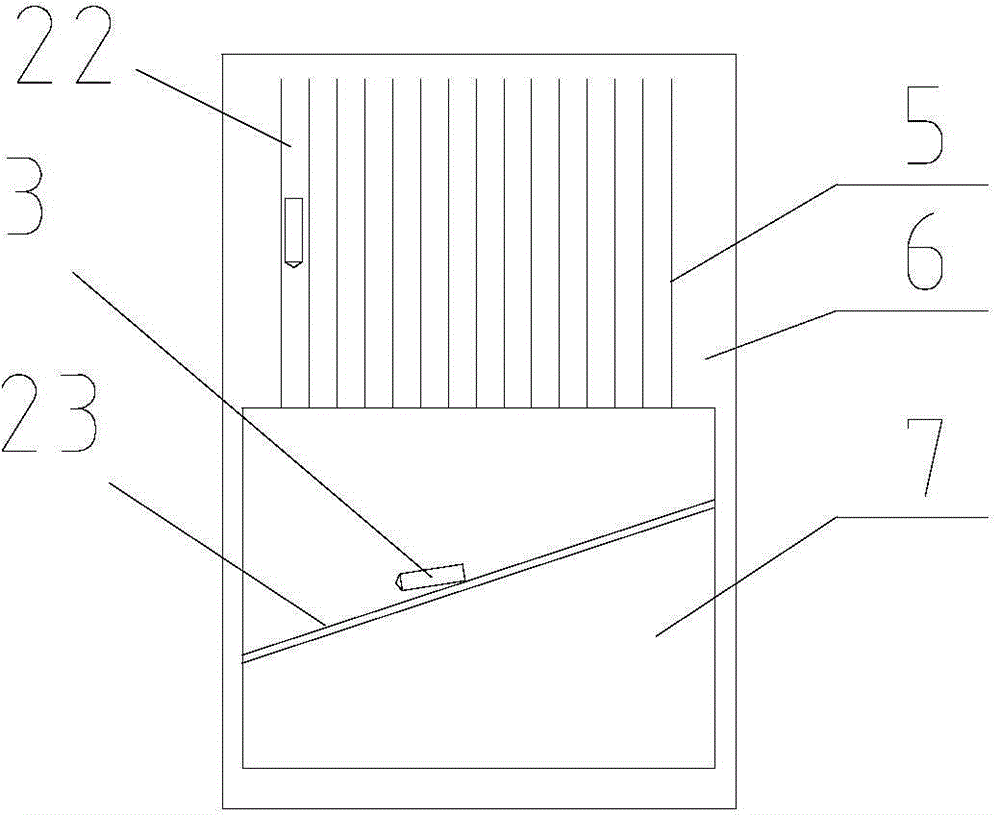

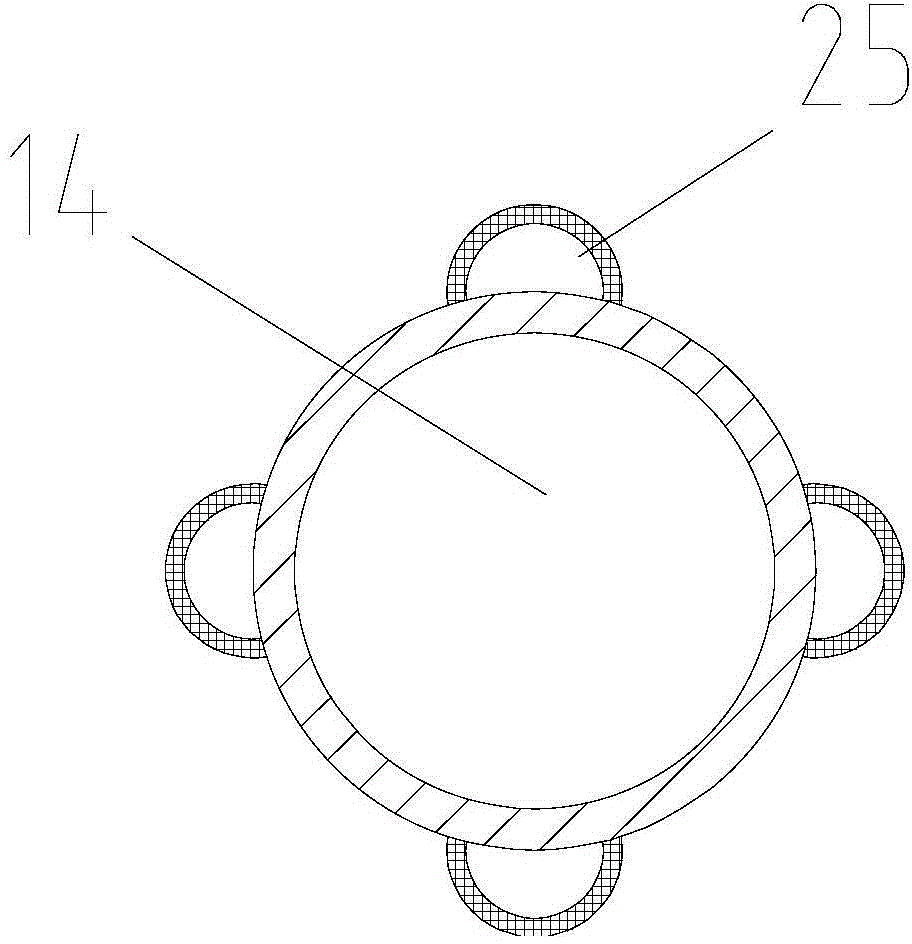

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the straightening mechanism is mainly composed of the material box 2, the first rubber roller 4, the grid plate 5, the smooth slope 6, the grid cover plate 7 and other parts. The material box 2 is fixedly connected with the frame 1, and the first rubber roller 4 is set on the outlet slope of the material box 1. The first rubber roller 4 is driven by a miniature DC gear motor, and a smooth slope 6 is connected under the outlet of the material box 2. A plurality of grid plates 5 are arranged longitudinally, and a plurality of grids 22 are formed between the plurality of grid plates 5. The lower end of the smooth slope 6 is provided with a second rubber roller 14, and the second rubber roller 14 is connected with a micro DC geared motor; the frame 1 is provided with a base plate 20 below the smooth slop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com