A film thickness test method of pin-disc friction machine under oil lubrication condition

A test method, pin-on-disc technology, applied to measuring devices, instruments, etc., can solve the problems of measuring film thickness and unable to quantitatively measure film thickness, etc., and achieve the effect of simple structure, low test cost and high accuracy of measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

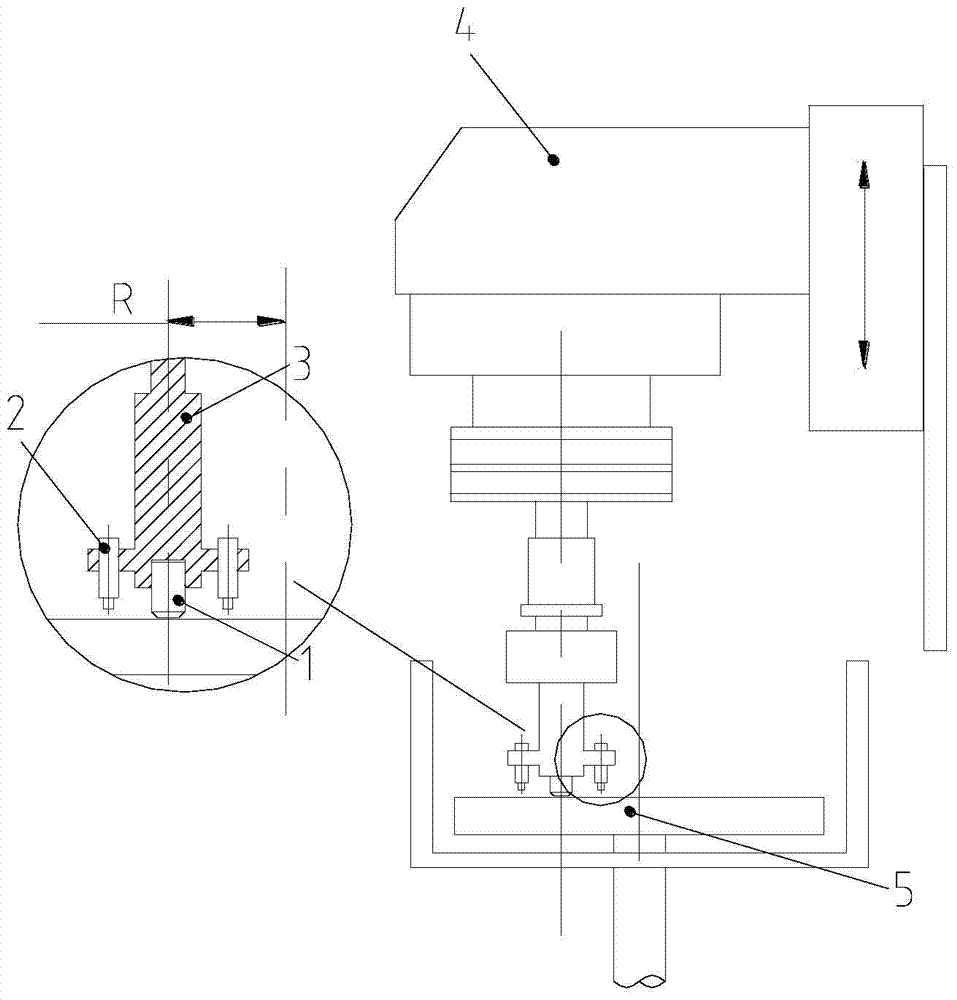

[0032] See attached figure 1 , (1) Install the displacement sensor 2 and the test pin 1 on the same end of the support 3, so that the axis of the test pin 1 coincides with the axis of the support 3, and the other end of the support 3 is fixed on the axis of the loading device 4 by a clamp , the loading device 4 can move vertically along the guide rail, and the friction disc 5 is located below the loading device 4 and the support 3;

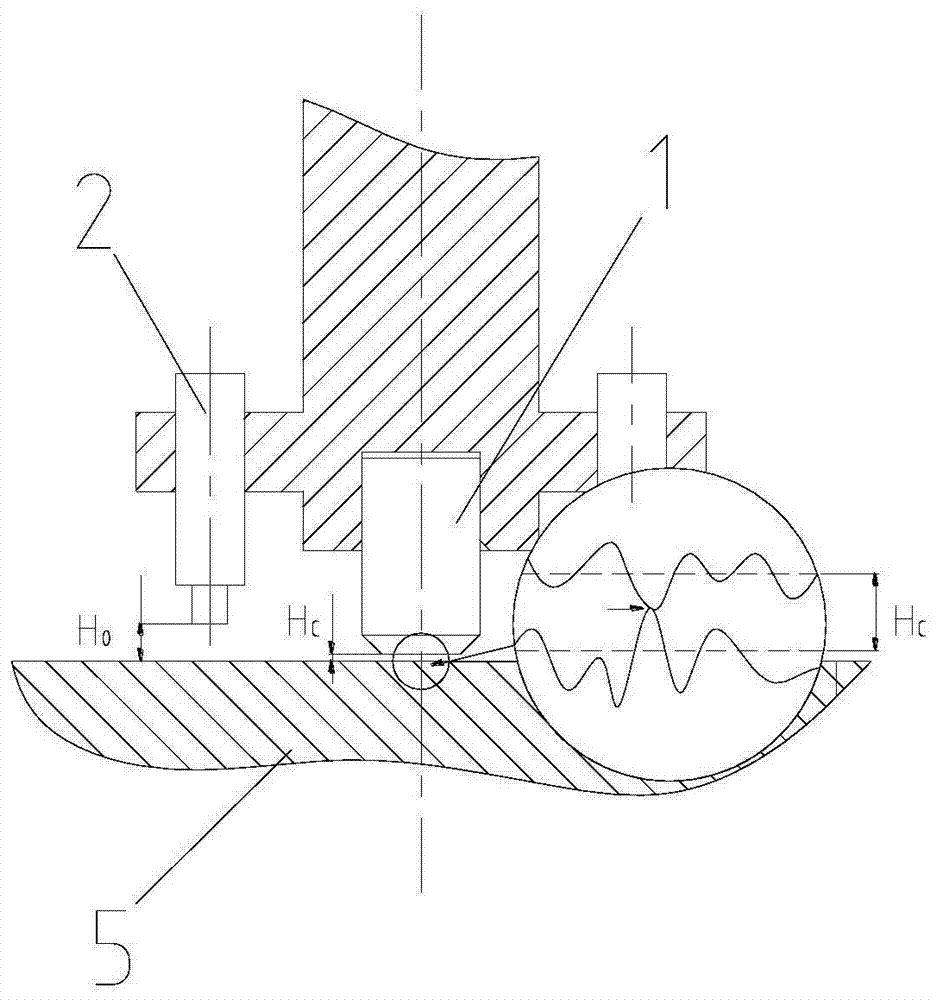

[0033] (2) adjust the relative position of displacement sensor 2 and test pin 1, make the bottom of test pin 1 protrude the distance of 0.3mm-0.4mm than the bottom of displacement sensor 2;

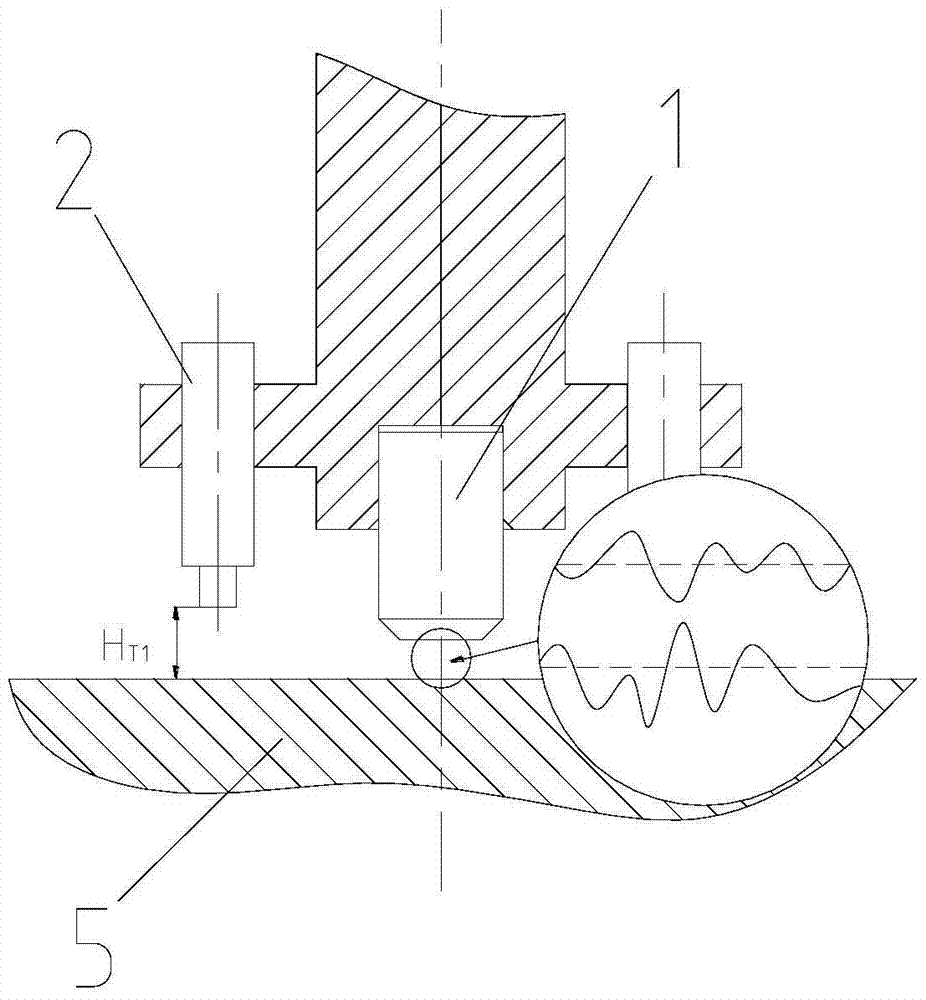

[0034] (3) Adjust the loading device 4 and the friction disc 5 by means of automatic zero adjustment and / or mechanical zero adjustment, so that the axis of the test pin 1 coincides with the axis of the friction disc 5, and then adjust the loading device 4 and the friction disc 5 The relative position of the test pin 1 is moved along the radial direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com