Reference signal constraint-based mechanical characteristic acoustic signal frequency-domain semi-blind extraction method

A reference signal and extraction method technology, which is applied in the field of mechanical equipment operation and maintenance, can solve the problems of weakening background noise interference, etc., and achieve the effect of weakening background noise interference, effective and accurate extraction, and simple test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: as Figure 1-8 As shown, a frequency-domain semi-blind extraction method of mechanical characteristic sound signals based on reference signal constraints, the specific steps of the frequency-domain semi-blind extraction method of mechanical characteristic sound signals based on reference signal constraints are as follows:

[0037] Step1. Initialize the structural parameters of the parts, calculate the characteristic frequency according to the structural parameters, construct the reference signal r(t), and perform centralization and whitening processing on the sound observation signal x(t) received by the microphone to remove the correlation between signals;

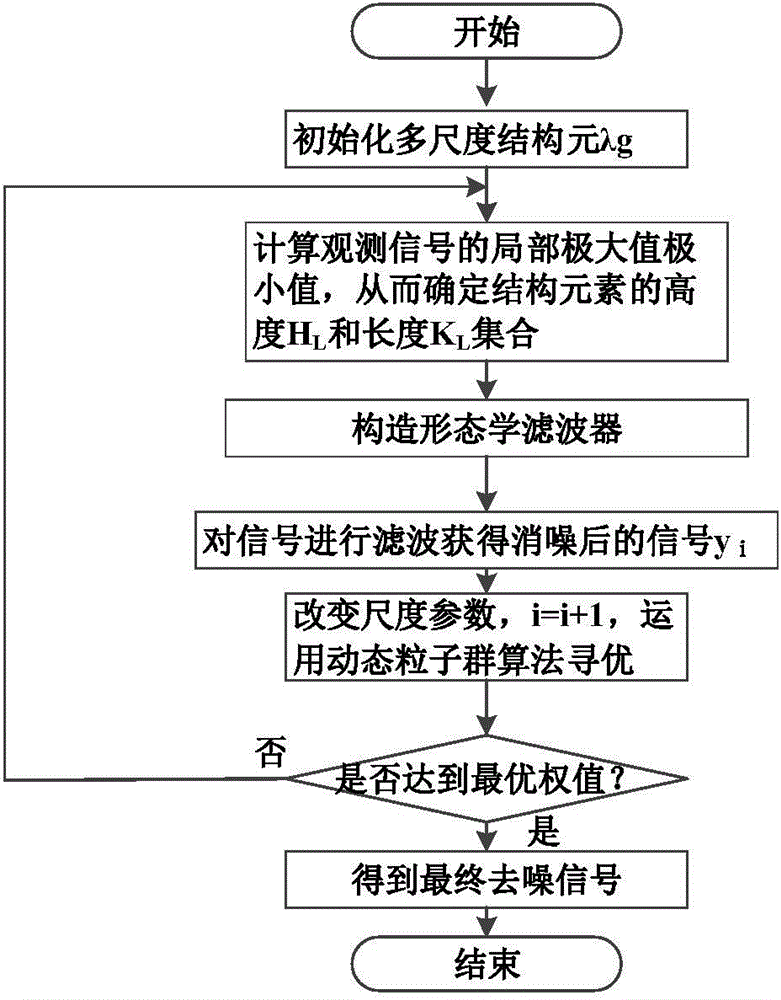

[0038] Step2. Use the improved multi-scale morphological filter to suppress the noise of the observation signal x(t), which is used to weaken the background noise interference to the greatest extent, and obtain the filtered time domain observation signal

[0039] Step3, use windowed STFT to observe ...

Embodiment 2

[0054] Embodiment 2: as Figure 1-8 As shown, a frequency-domain semi-blind extraction method of mechanical characteristic acoustic signals based on reference signal constraints, this embodiment is the same as Embodiment 1, the difference is that this embodiment uses the acoustic extraction of rolling bearing faults in a rotating test bench in the actual sound field The experiment is an implementation example:

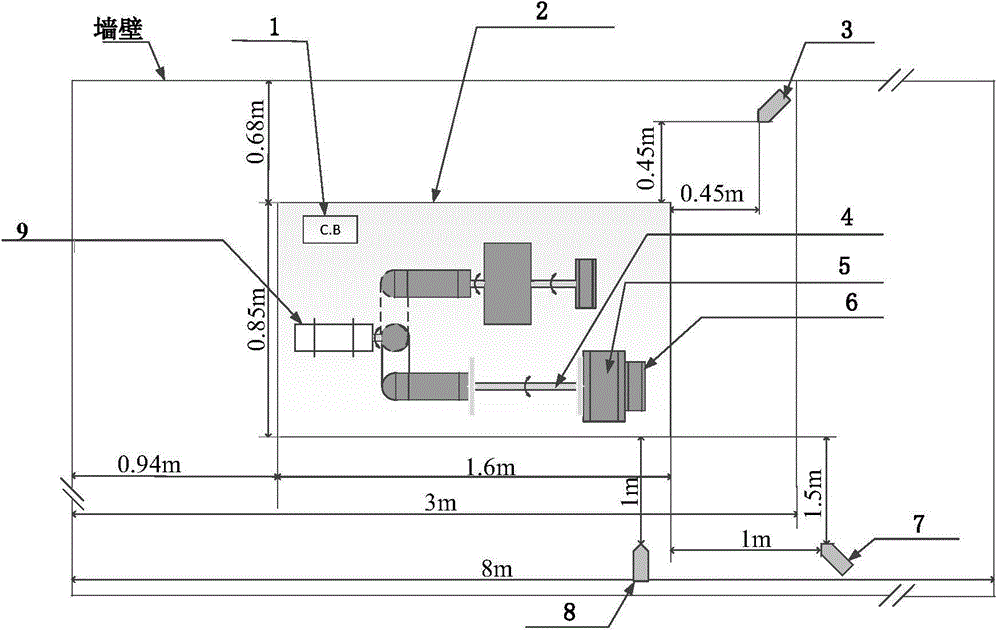

[0055] figure 1 Indicates the positional relationship between the two microphones and the test bench, the control box 1 is connected to the motor 9 through wires, the motor 9 is connected to the transmission shaft 4, the faulty bearing 6 is installed in the bearing seat 5, and is driven by the transmission shaft 4 to rotate. Microphone I 3, microphone II 7, and microphone III 8 are all 1m above the ground, and microphone I 3 and microphone II 7 are at a 90° angle to each other. Microphone III 8 is placed vertically on test bench 2. Microphone I 3, microphone II 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com