Platinum rhodium thermal coupler

A thermocouple, platinum-rhodium technology, applied in the field of thermocouples, can solve the problems of difficult to block the heat transfer between the heated part and the junction box, high sealing requirements, affecting the service life, etc., to achieve good sealing, prolong service life, improve The effect of temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

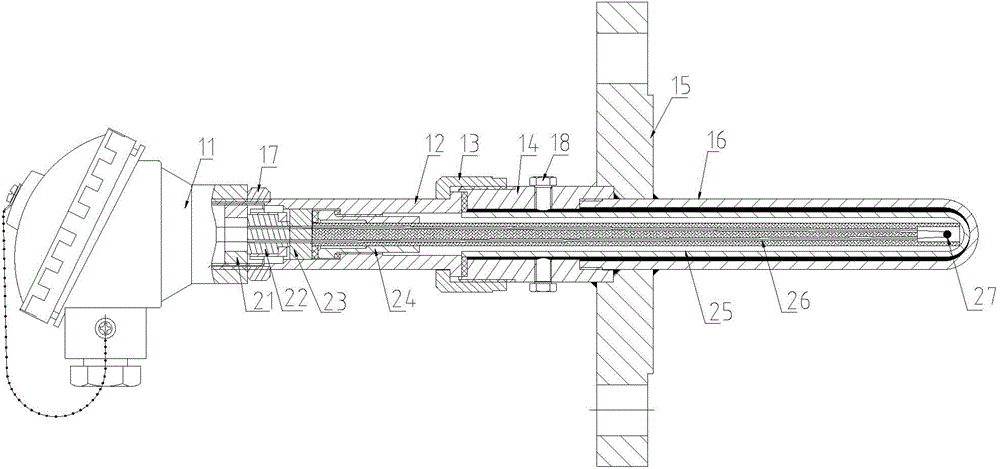

[0017] like figure 1 shown, figure 1 It is a schematic structural diagram of a platinum-rhodium thermocouple proposed by the present invention.

[0018] refer to figure 1 , the present invention proposes a platinum-rhodium thermocouple, including a junction box 11, an upper pipe 12, a connecting nut 13, a flange pipe 14, a flange 15, a protection pipe 16, a seal 23, a first corundum pipe 25, a second Corundum tube 26, platinum rhodium wire 27;

[0019] The junction box 11 is threadedly connected with one end of the upper connecting pipe 12, the other end of the upper connecting pipe 12 is provided with a flange that protrudes outward, the outer wall of one end of the flange connecting pipe 14 is provided with a thread, and one end of the upper connecting pipe 12 close to the flange is provided with a connecting nut. 13 is connected to the flanged pipe 14, the side wall of the flanged pipe 14 is provided with a threaded through hole and a fastener 18 mounted on the through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com