Automatic liquid concentration measuring method

A liquid concentration and automatic detection technology, applied in the direction of measuring device, specific gravity measurement, material analysis by measuring buoyancy, etc., can solve the problems of low precision, gap measurement, poor long-term reproducibility, etc., and achieve high precision and low cost , The effect of reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

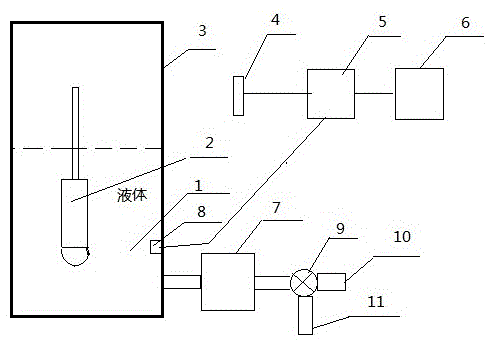

[0020] The present invention will be further described below in conjunction with accompanying drawing and example. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only parts related to the present invention are shown in the drawings but not all content.

[0021] In this embodiment, the liquid concentration automatic detection method specifically includes the following steps:

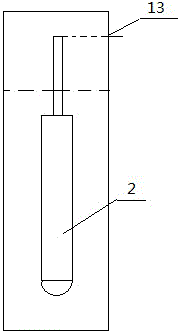

[0022] A. Select the buoyancy meter 2 with the required accuracy;

[0023] B. Proportion the two concentrations of solutions within the range of the buoyancy meter, so that one of them is close to the maximum value and the other is close to the minimum value. Use the camera to obtain the positions of the buoyancy meter marking lines in the image under these two conditions, and record the current p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com