Method for automatically detecting printing defects of remote controller panel based on SURF (Speed-Up Robust Feature) algorithm

A technology for automatic detection of printing defects, applied in the field of image processing, can solve problems such as large amount of calculation, difficulty in finding the best matching position, and difficulty in achieving real-time performance, so as to reduce false matching points, meet real-time requirements, and fast calculation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

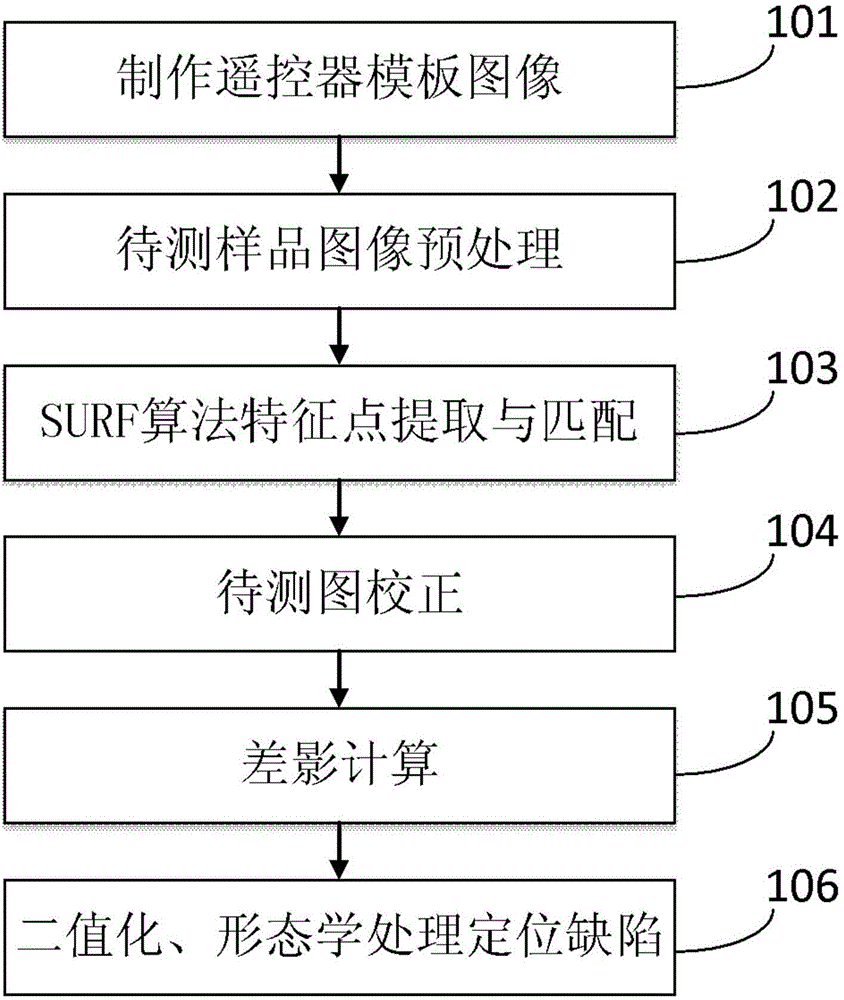

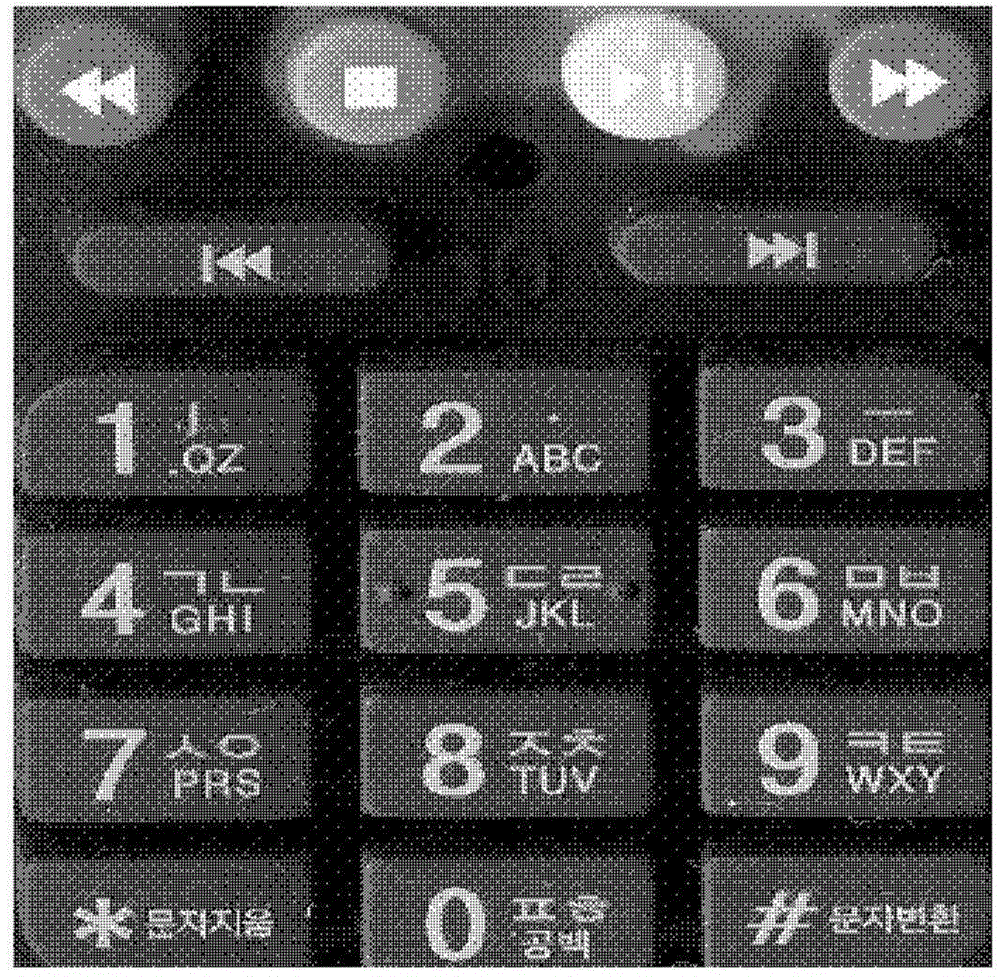

[0045] In order to verify the measurement effect of the remote control defect automatic detection method based on the SURF algorithm provided by the present invention, the following experiment was carried out: considering that the original remote control picture is too large, a part of the remote control sample picture is selected as an example of the experimental result. After selecting multiple non-defective standard remote control samples, calculating the average gray value and cutting off the irregular edges, the standard template produced is as follows: image 3 shown. Figure 4 It is a sample picture of the remote control to be tested collected by the imaging system. The picture has been rotated and has 3 obvious content defects, namely the white area of the round button in the upper right corner, the Korean letters next to the number 1 key and the number 8 key . The feature points of the two complete images calculated according to the SURF algorithm are 624 and 636, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com