Device for rapidly aging and evaluating SCR catalyst powder

An SCR catalyst and rapid aging technology, which is applied in the field of catalyst aging and evaluation test system devices, can solve the problems of difficult control of engine bench tests, inability to rapidly age catalysts, and inability to perform accurate exhaust gas simulation in fixed bed reactors. Avoid direct contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

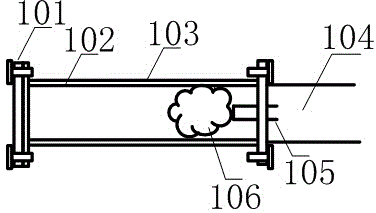

[0021] Such as figure 1 As shown, it is a diagram of the catalyst small sample reaction device, which is mainly composed of a connection and fixing device 101, a quartz tube 102, a steel pipe 103, an exhaust outlet 104, a quartz wool fixing device 105, and a quartz wool 106. The quartz tube used in the reaction is a general-purpose quartz tube for a fixed-bed reactor. The wall is thin and fragile and cannot withstand high pressure. If a metal tube is used directly, it is easy to cause the catalyst and tail gas components to react with it. Therefore, the outer side of the quartz tube is covered with a corresponding thin Steel tubes, quartz tubes and steel tubes are directly connected with corresponding ferrules and bolts. In order to prevent the catalyst from being blown away and blown away in the quartz tube, quartz wool and corresponding quartz wool fixing devices are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com