Device and method for detecting high-voltage interlocking failure of electric vehicle

A high-voltage interlocking and fault detection technology, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve problems such as failure to determine the failure of high-voltage connectors, achieve accurate diagnosis, save time, and reduce workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

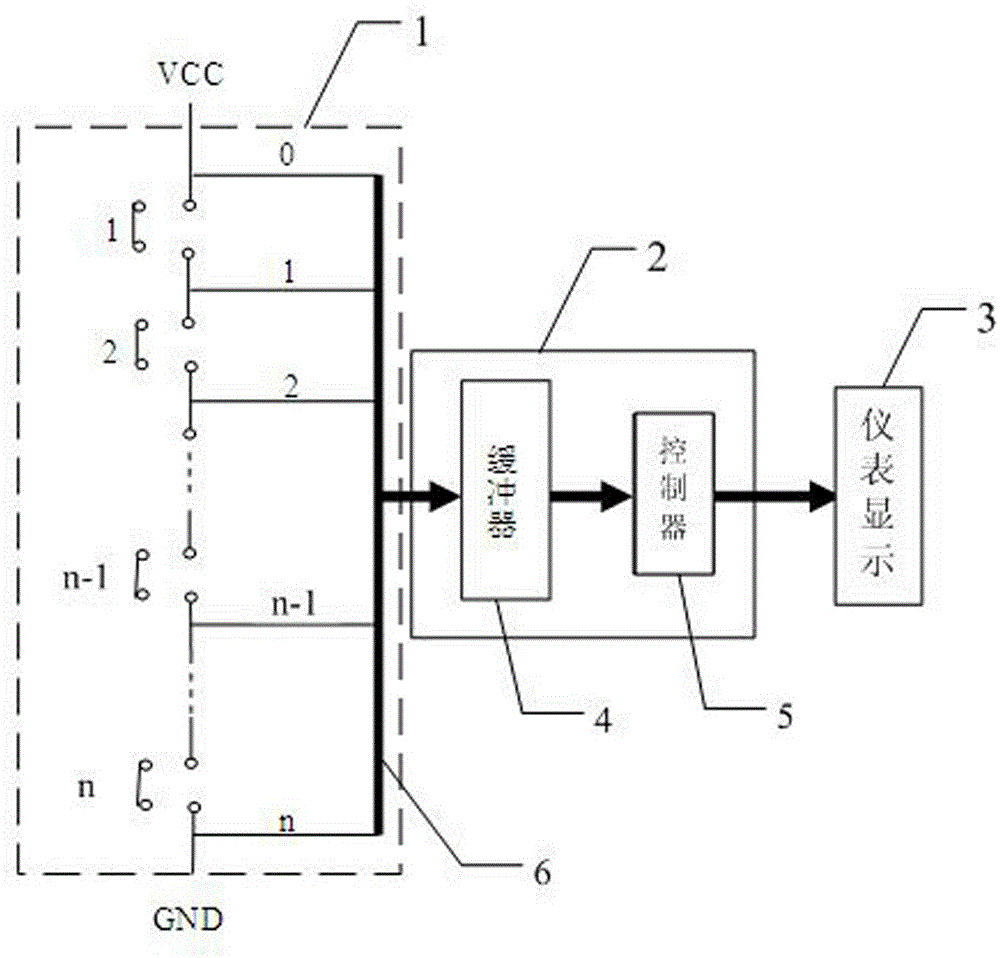

[0023] The high-voltage interlock fault detection device for electric vehicles in this embodiment, such as figure 1 shown. It includes a high-voltage interlock plug-in 1, an interlock fault detection device 2 and an instrument display 3. The high-voltage interlock plug-in 1 is sequentially connected to the fault detection device 2 and the instrument display 3 through the data bus 6 .

[0024] The fault detection device 2 is composed of a buffer 4 and a controller 5 , and the high-voltage interlock plug-in 1 is sequentially connected with the buffer 3 and the controller 4 of the interlock fault detection device 2 . In this embodiment, the buffer 4 used in this embodiment is composed of a three-state eight-way buffer model 74LS244 and a three-state eight-way buffer model 74ALS245 connected in series. For example, when the high-voltage interlock circuit is composed of 7 high-voltage interlock plug-ins, that is figure 1 When n=7, one end of the 0th signal line is connected to t...

Embodiment 2

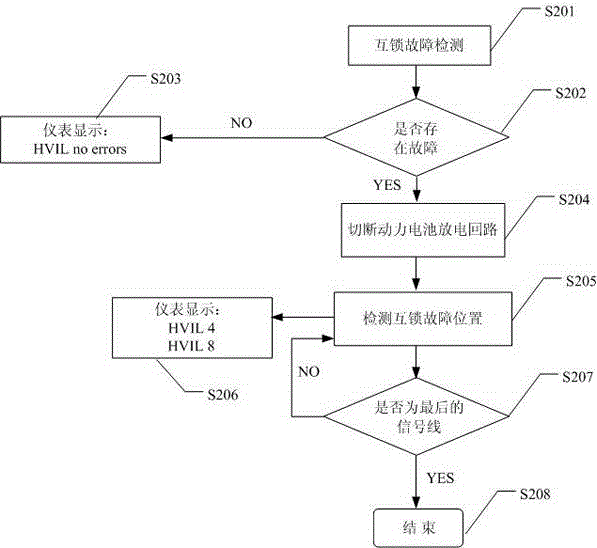

[0029] A kind of electric vehicle high-voltage interlock fault detection method adopted in this embodiment, such as figure 2 shown, including the following steps:

[0030] In step 201, when the whole vehicle is in the ignition (Key on) state, the voltage levels at both ends of the high voltage interlock plug-in are detected. The controller receives the level signal from both ends of the high-voltage interlock plug-in of the buffer through the bus bar, and the controller selects to receive the level signal at both ends of any high-voltage interlock plug-in according to needs.

[0031] In step 202, if the 0th signal line and the nth signal line are detected, if both are at high level, it means that the high voltage interlock circuit is normal, and step 203 is executed. In step 203, it is displayed that there is no error in the circuit, such as HVIL no errors, that is, the high voltage interlock circuit has no fault;

[0032] If the 0th signal line is at high level and the nth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com