Superconductive magnetic suspension supporting arrangement

A support device and magnetic levitation technology, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of inconvenient system assembly, complex spherical coil assembly and positioning, difficult modular design, etc., to simplify system control and mechanical structure, The effect of simplifying the fault repair process and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and specific embodiments.

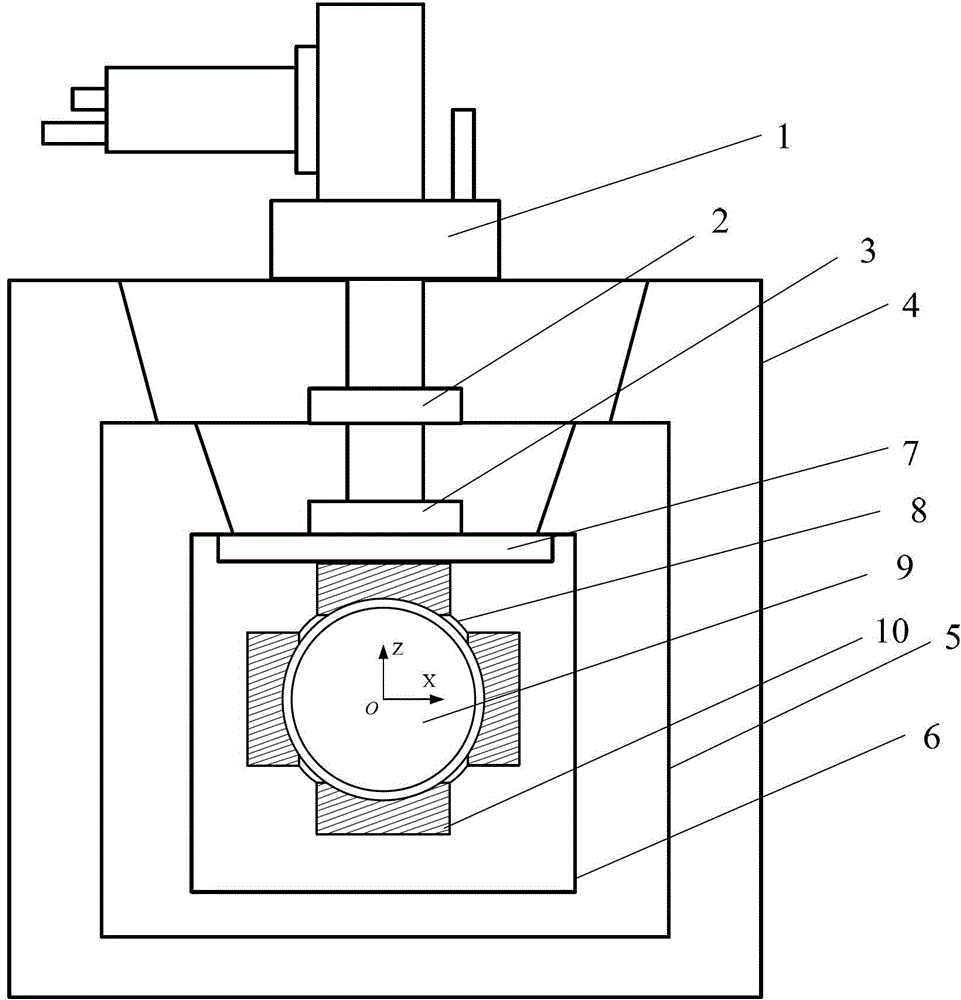

[0019] Such as figure 1 As shown, the mechanical part of the device of the present invention includes a refrigerator 1, a cryogenic container 4, a cold shield 5, a liquid helium container 6, a mounting cover 7, a rotor cavity 8, a superconducting rotor 9 and a support module 10. The refrigerator 1 is installed at the upper end of the low-temperature container 4, and the primary cold head 2 of the refrigerator 1 is located inside the low-temperature container 4. The cold shield 5 is in the shape of a reel, placed inside the cryogenic container 4, and fixed to the lower part of the upper end cover of the cryogenic container 4 by a tie rod with high strength and low thermal conductivity. At the same time, the upper end of the cold shield 5 is in line with the primary cooling of the refrigerator 1. The lower end faces of the head 2 are fastened together by bolts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com