Spray device and method for manual ice coating of ultra-high voltage equipment

A spray device and ultra-high voltage technology, applied in the field of electrical engineering, can solve the problems of complicated operation and short icing distance, and achieve the effects of uniform spray, convenient operation and maintenance, and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

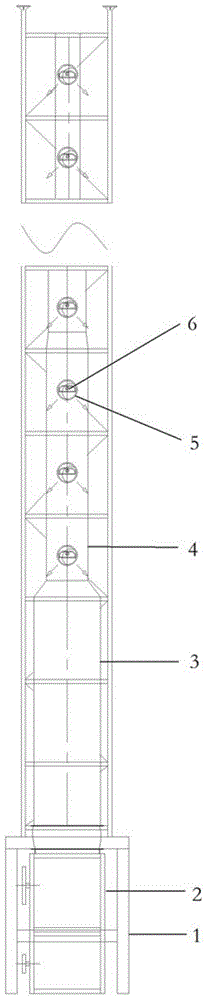

[0026] In the embodiment of the present invention, the climate artificial simulation indoor UHV equipment is artificially iced with a tapered spray air supply bellows, such as figure 1 As shown, the mounting bracket 1 is made of ordinary stainless steel square tube; the variable frequency induction fan 2 is an explosion-proof centrifugal fan of model B4-72 (79) produced by Zhejiang Shangyu Sanhe Fan Co., Ltd., and its air volume is 4420- 48800m 3 / h, the wind pressure is 317-2118Pa; the static pressure box 3 is made of ordinary hot-dip galvanized steel plate with a thickness of 1.5mm to make a square pipe, and its size is 800mm (length) × 700mm (width) × 2400mm (height); taper The type air supply bellows 4 is made of ordinary hot-dip galvanized steel sheet with a thickness of 1.5mm to form a square pipe. There are four levels in total. Three spherical air outlets 5 and three ice-coated nozzles 6 are evenly installed on each level. The first level is a cubic bellows. The size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com