Automatic test system and test method

A technology for automated testing and test benches, which is applied to measuring devices, measuring electrical variables, instruments, etc., to achieve the effects of improving utilization, reducing operating costs, and shortening time periods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

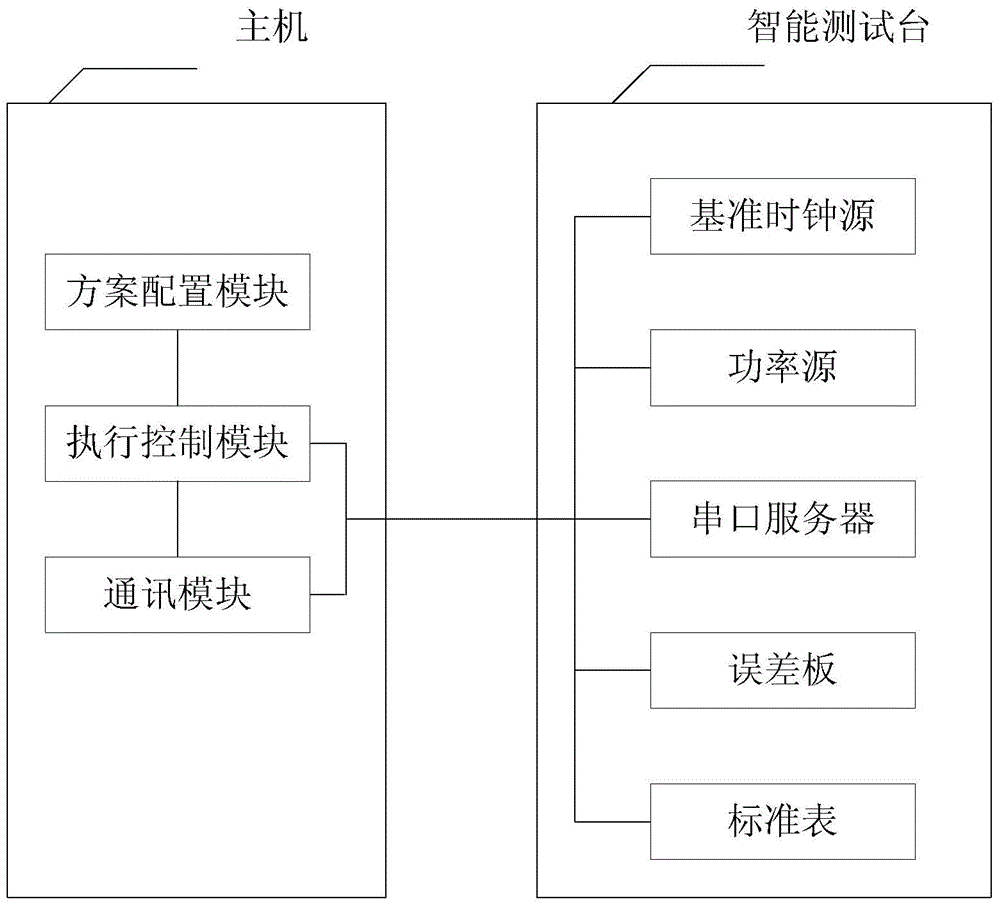

[0024] refer to figure 1 .

[0025] The present invention provides an automated test system, comprising a host and an intelligent test platform, the host and the intelligent test platform are connected through a data line; the host includes an execution control module, a communication module and a scheme configuration module, and the communication module is connected to The scheme configuration modules are all connected with the execution control module; the test equipment includes a plurality of power sources, a plurality of error boards, a serial port server, a reference clock source, a standard table and a plurality of table positions, and a plurality of the power sources , a plurality of the error boards, a reference clock source and a standard meter are all connected to the serial port server; a plurality of the meter positions are used to place external instruments to be tested, and each meter position is provided with a power source and an error board; The number of th...

Embodiment 2

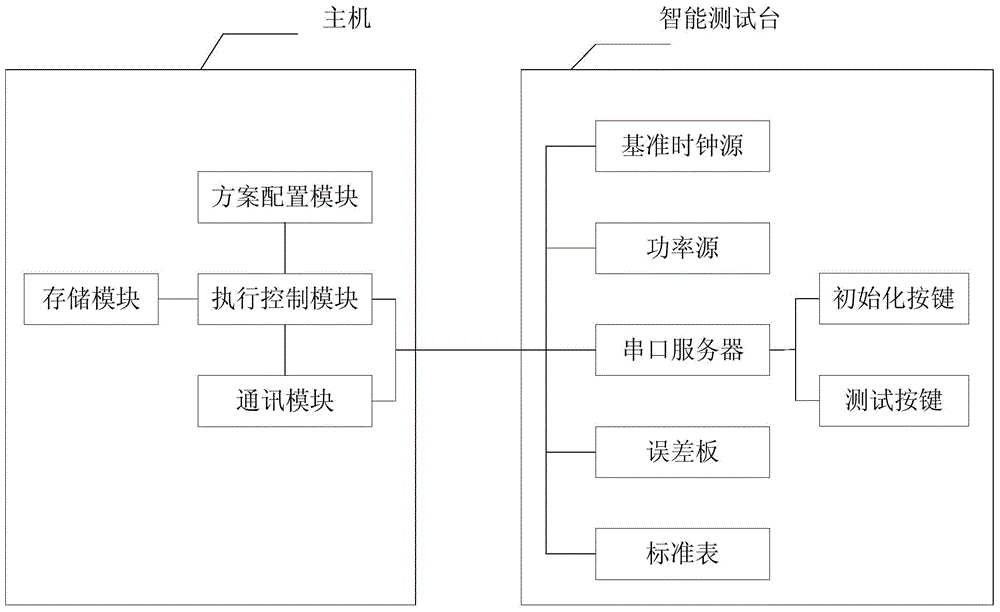

[0034] refer to figure 2 .

[0035] The present invention provides an automated test system, comprising a host and an intelligent test platform, the host and the intelligent test platform are connected through a data line; the host includes an execution control module, a communication module and a scheme configuration module, and the communication module is connected to The scheme configuration modules are all connected with the execution control module; the test equipment includes a plurality of power sources, a plurality of error boards, a serial port server, a reference clock source, a standard table and a plurality of table positions, and a plurality of the power sources , a plurality of the error boards, a reference clock source and a standard meter are all connected to the serial port server; a plurality of the meter positions are used to place external instruments to be tested, and each meter position is provided with a power source and an error board; The quantity of...

Embodiment 3

[0041] see again figure 2 .

[0042] The invention provides a test method for an automated test system, comprising the steps of:

[0043] S1: Place the meter under test

[0044] The external instrument to be tested is placed on the table position; the initialization button is pressed, and the initialization button generates a trigger signal, and the trigger signal is sent to the executive through the communication link generated by the serial server and the communication module. control module.

[0045] S2: Smart test bench initialization

[0046] The execution control module calls the test scheme file generated by the scheme configuration module, and the execution control module, according to the test configuration file, uses the serial port server for the power source, error board, The standard board and the reference clock source send initialization control commands.

[0047] S3: Start testing the external instrument under test

[0048] Press the test button, the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com