Reinforcing structure and preparation method and liquid crystal screen assembly and preparation method

A liquid crystal display, reinforced technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of easy deformation of colloid, easy product quality, large amount of optical glue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

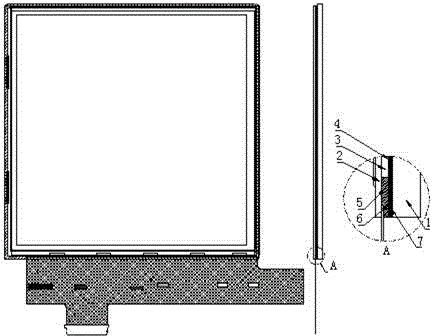

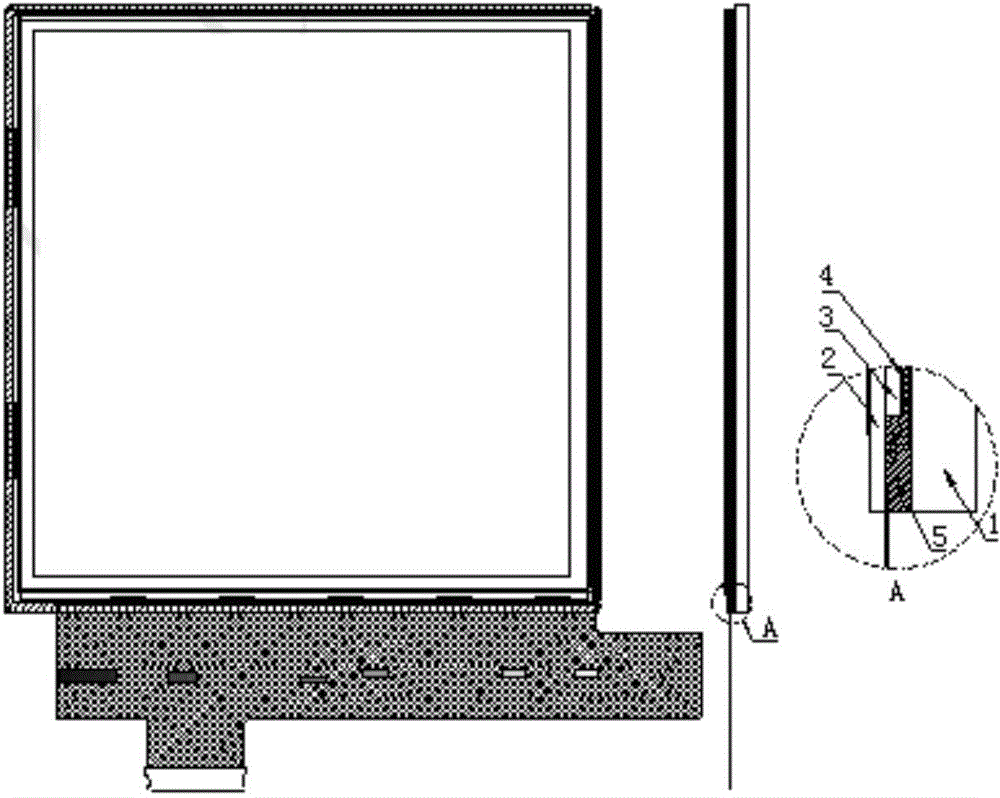

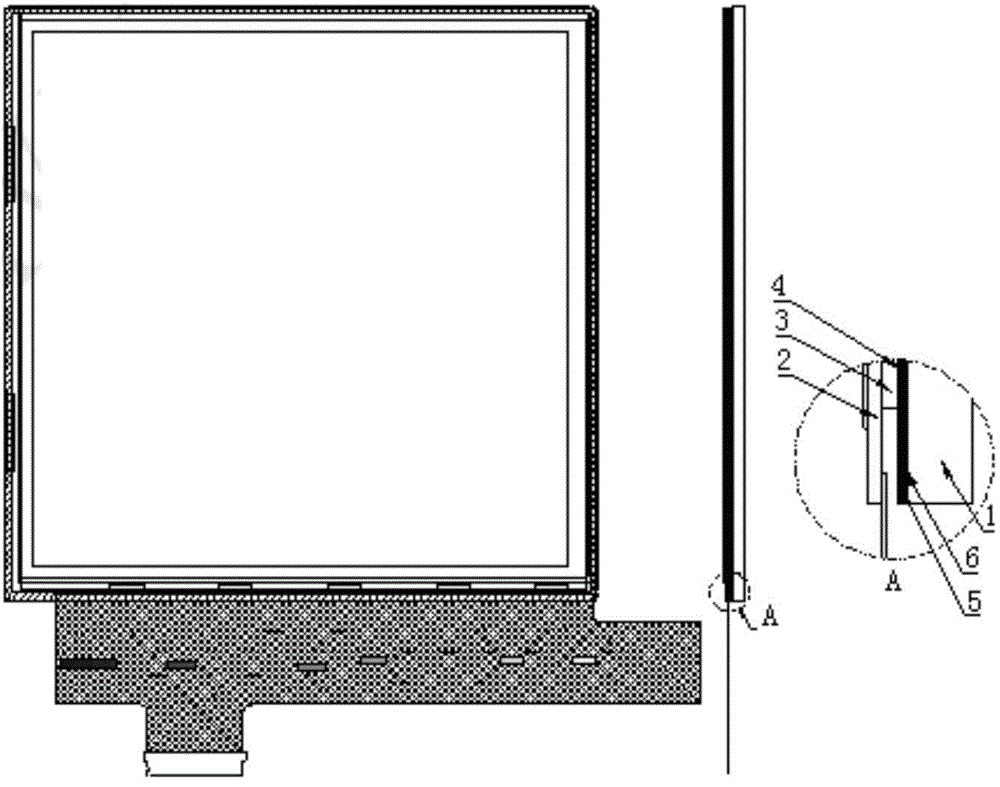

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0036] In order to avoid the colloid being easily deformed due to high temperature during actual use, and thus prone to product quality problems, under the funding of the "National Special Funding for International Science and Technology Cooperation" fund project (Project No.: 2013DFR80830), a series of technical researches were carried out and summarized A solution to significantly improve the failure of high-temperature Mura (the phenomenon of uneven brightness of the display, causing various traces) is proposed. This scheme will be specifically described below.

[0037] In the present invention, in the absence of a contrary description, the orientation words...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com