Disposable laser anti-counterfeiting label and manufacturing method thereof

A technology of laser anti-counterfeiting and manufacturing methods, which is applied to the printing, printing device, and printing of special varieties of printed matter, which can solve the problems that the anti-counterfeiting identification effect of commodities cannot be fully achieved, and the anti-counterfeiting labels are easy to copy and reusable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

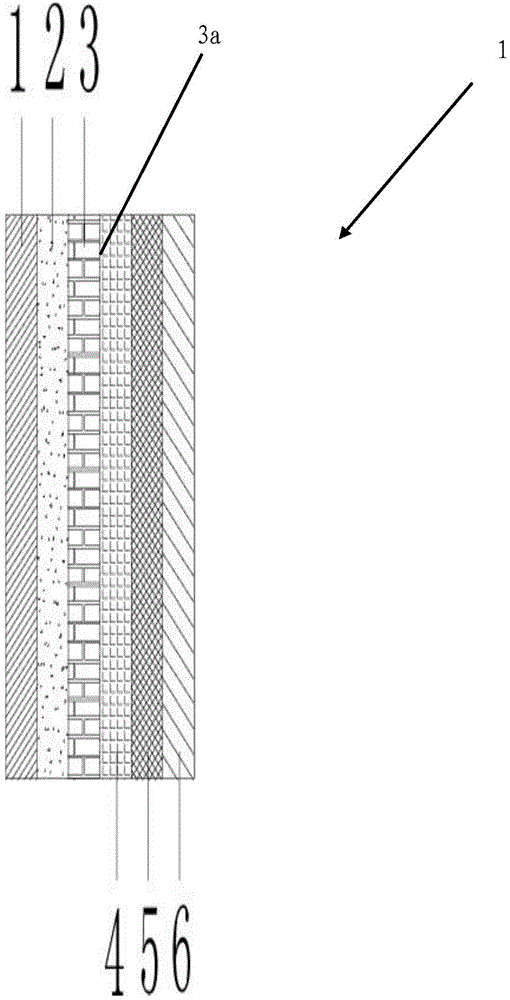

[0028] Such as figure 1 As shown, the disposable laser anti-counterfeiting label 1 of the present embodiment includes a base film 1, a laser holographic layer 2 coated on one surface of the base film 1, an aluminum layer 3 coated on the laser information layer 2, printed on An anti-counterfeiting code 4 on the aluminum layer 3, a pressure-sensitive adhesive layer 5, and a substrate layer coated with silicon paper 6.

[0029] Among them: base film 1 adopts 30, 35, 40, 45 or 50um thick PVC / PET film;

[0030] The laser holographic information layer 2 adopts water-based or solvent-based transfer coating, the solid content of the transfer coating is 20-25% (specifically 20%, 22% or 25%), and the softening point is 120-135°C (specifically 120°C, 125% ℃, 130℃ or 135℃), the acid value is 15-30mg KOH / g (specifically 15mg KOH / g, 20mg KOH / g, 25mg KOH / g or 30mg KOH / g), and the dry coating amount is 1.5-2.5 g / m 2 (specifically 1.5g / m 2 , 2.0g / m 2 , or 2.5g / m 2 ).

[0031] The thick...

Embodiment 2

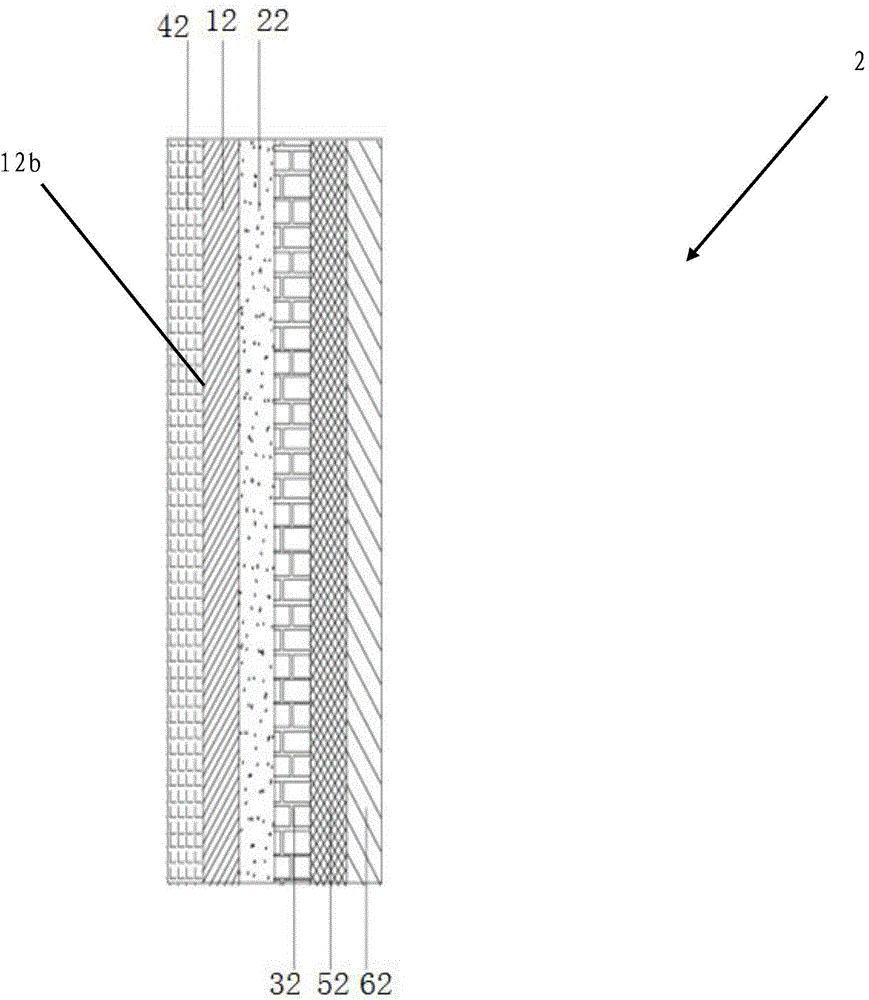

[0036] Such as figure 2 As shown, the disposable laser anti-counterfeiting label 2 of the present embodiment includes a base film 22, an anti-counterfeiting code 12 printed on the base film 22, a laser holographic layer 32 coated on one surface of the base film 22, and a The aluminum layer 42 on the laser information layer 32, the pressure-sensitive adhesive layer 52, and the substrate layer coated with silicon paper 62. in:

[0037] The anti-counterfeit code layer 12 is a variable anti-counterfeit code such as a one-dimensional code, a two-dimensional code or a three-dimensional code.

[0038] The base film 22 is a 30-50um thick PVC / PET film;

[0039] The laser holographic information layer 32 adopts water-based or solvent-based transfer coating, the solid content of the transfer coating is 20-25%, the softening point is 120-135°C, the acid value is 15-30mg KOH / g, and the dry coating amount is 1.5-2.5 g / m 2 .

[0040] The aluminum layer 42 has a thickness of 300, 350, 4...

Embodiment 3

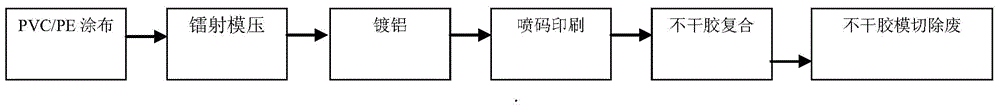

[0043] Embodiment three, the manufacture of disposable laser anti-counterfeit label 1 and 2:

[0044] Such as image 3 As shown, the specific process steps for manufacturing disposable laser anti-counterfeiting labels 1 and 2 are as follows:

[0045] Step 1: First, use PVC / PET film (1 or 12) to coat the holographic laser coating layer (2 or 22) on the coating machine, and then use infrared drying and curing to form a coating film;

[0046] Step 2: Carry out holographic molding on the coating film on a laser molding machine to form a laser holographic film;

[0047] Step 3, using a vacuum aluminum coating machine to plate an aluminum layer (3 or 32) on the coating surface of the laser film, the thickness of the aluminum layer is 300 to 500 angstroms, forming an aluminum-coated laser film;

[0048] Step 4, using a code jet printing machine to print variable anti-counterfeit codes (4 or 42) on the aluminum-plated surface (3a) or the PVC / PET film surface (12b);

[0049] Step 5, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com