Self-cleaning vacuum treatment chamber

A vacuum treatment and self-cleaning technology, which is applied to electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as low efficiency, achieve the effect of improving service life and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0023] This article will describe the present invention in conjunction with a plasma processing chamber (typically an etching tool). However, those skilled in the art should understand that the present invention is applicable to plasma etching equipment, chemical vapor deposition equipment, MOCVD equipment and the like.

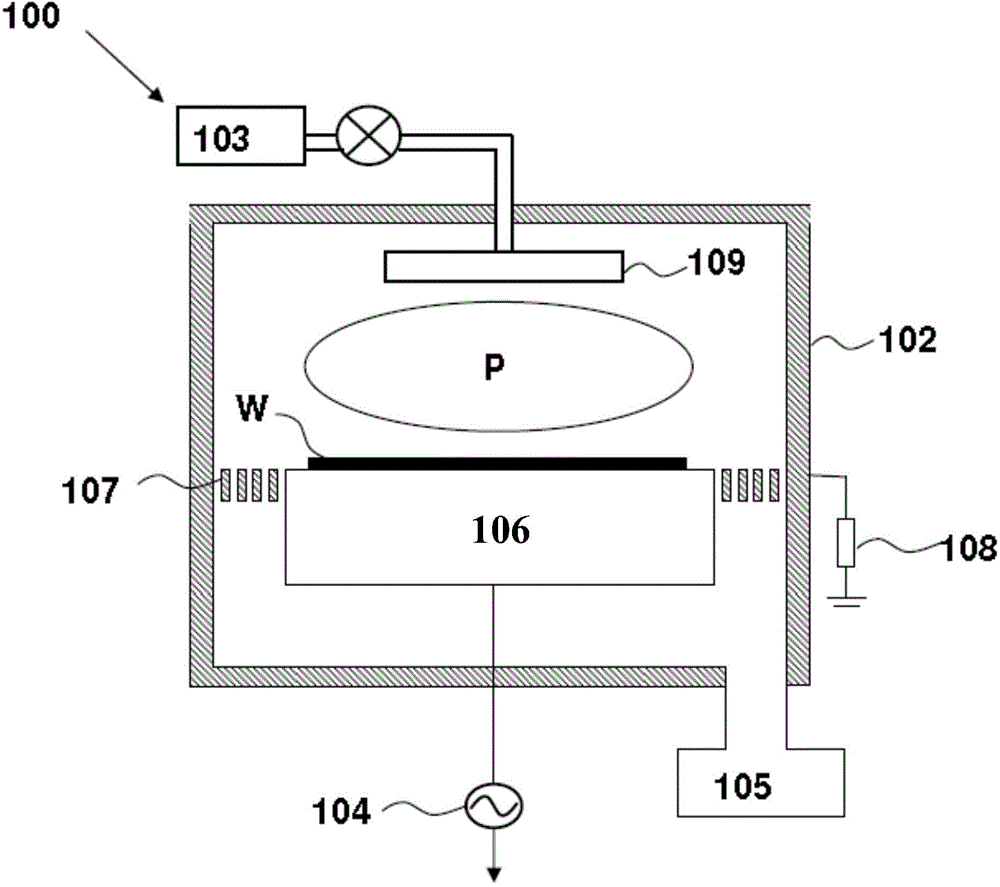

[0024] figure 1 is a schematic diagram of the structure of the plasma processing chamber. The plasma processing chamber 100 has a processing chamber 102 which is substantially cylindrical and has substantially vertical side walls. The upper electrode 109 and the lower electrode are arranged parallel to each other in the processing chamber 102 . Typically, the area between the upper electrode 109 and the lower electrode is the processing area P where high frequency energy will be developed to ignite and sustain the plasma. A subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com