Current coordination control method of mixed excitation motor

A hybrid excitation motor and control method technology, applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve the problems of no general control method for motors, etc., to save energy costs, improve utilization and efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

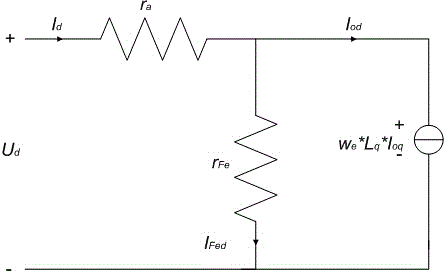

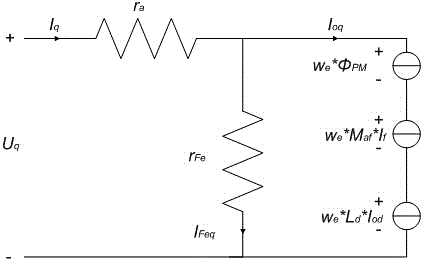

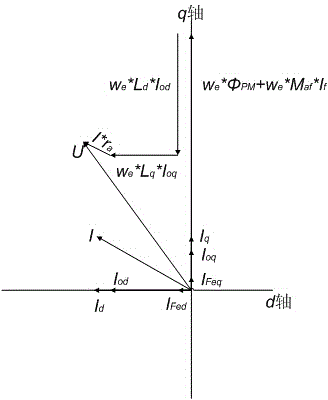

[0028] In order to solve the problems existing in the prior art, the present invention proposes a current coordinated control strategy for the hybrid excitation motor, so that the electromagnetic loss of the motor has a functional relationship with the armature current, the internal power factor angle, and the excitation current. According to the input The mechanical speed and output mechanical power of the motor and other parameters of the motor are solved to solve the armature current, internal power factor angle and excitation current, so that the electromagnetic loss of the motor can be minimized, and the optimal control of the motor can be realized, and a calculation hybrid Flux Regulation of Excited Motors α ( α = the permanent magnet flux of each phase winding / the maximum value of the total flux of each phase winding) so that the method with the highest efficiency when the hybrid excitation motor is running at the normal operating point.

[0029] The present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com