Initial magnetic-inductive capacity 20 (+4) (-4) nickel-zinc ferrite material and preparation method

A technology of nickel-zinc ferrite and initial magnetic permeability, applied in the direction of magnetism of inorganic materials, can solve the problems of ferrite eddy current loss increase, increase production cost, reduce lamp efficiency, etc., achieve good temperature characteristics, broadband and low electromagnetic loss, the effect of good electromagnetic loss characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

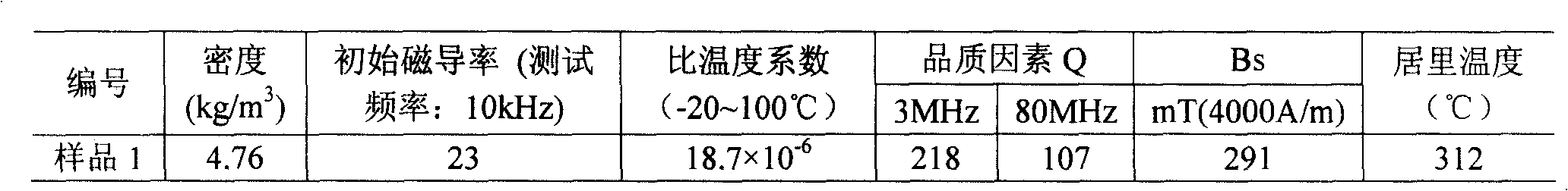

Embodiment 1

[0032] 1) selection of raw material: a kind of nickel-zinc ferrite material and preparation method with an initial magnetic permeability of 23 provided by the present embodiment, its raw material selects industrially pure Fe 2 o 3 , ZnO, MnCO 3 , NiO and CoO.

[0033] 2) Composition design and weighing: according to Fe 2 o 3 49mol%, ZnO 6mol%, MnCO 3 1 mol%, NiO 42.7 mol%, and CoO 1.3 mol%.

[0034] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water, the weight of deionized water is 1.2 times of the total weight of raw materials, and the ball milling time is 2 hours.

[0035] 4) Pre-burning: Dry the raw materials that have been ball-milled once, and put them into an electric furnace for pre-burning. The pre-burning temperature is 950°C, and the pre-burning time is 3.5 hours. After pre-burning, it is cooled with the furnace. After pre-burning, XRD phase analysis was carried out on the pre-fired material, and it was confirmed th...

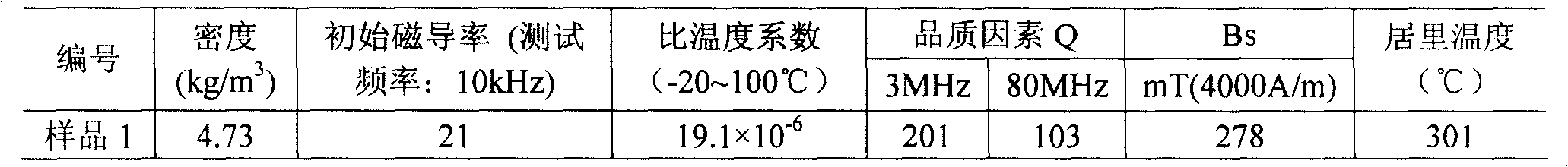

Embodiment 2

[0043] 1) Selection of raw material: a kind of nickel-zinc ferrite material and preparation method with an initial magnetic permeability of 21 provided in this embodiment, its raw material selects industrially pure Fe 2 o 3 , ZnO, MnCO 3 , NiO and CoO.

[0044] 2) Composition design and weighing: according to Fe 2 o 3 46mol%, ZnO 2.4mol%, MnCO 3 0.1 mol%, NiO 49 mol%, and CoO 2.5 mol%.

[0045] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water, the weight of deionized water is 1.2 times of the total weight of raw materials, and the ball milling time is 1 hour.

[0046] 4) Pre-burning: Dry the raw materials that have been ball-milled once, and put them into an electric furnace for pre-burning. The pre-burning temperature is 1100°C, and the pre-burning time is 1.5 hours. After pre-burning, it is cooled with the furnace. After pre-burning, XRD phase analysis was carried out on the pre-fired material, and it was confirmed that on...

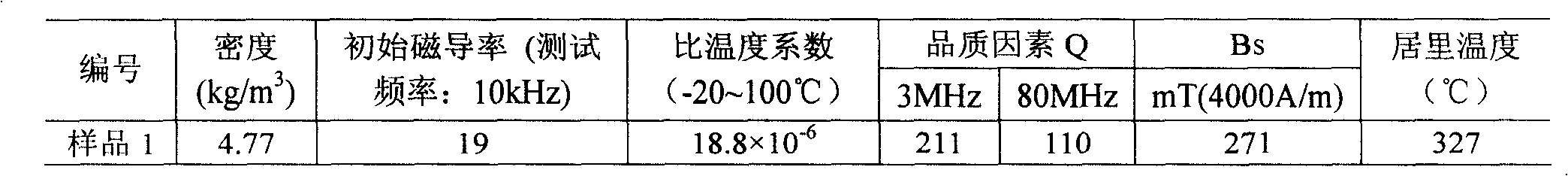

Embodiment 3

[0054] 1) Selection of raw materials: a kind of nickel-zinc ferrite material with an initial magnetic permeability of 19 and its preparation method provided by the present embodiment, its raw material selects industrially pure Fe 2 o 3 , MnCO 3 , NiO and CoO.

[0055] 2) Composition design and weighing: according to Fe 2 o 3 49mol%, MnCO 3 0.4 mol%, NiO 49 mol%, and CoO 1.6 mol%.

[0056] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water, the weight of deionized water is 1.2 times of the total weight of raw materials, and the ball milling time is 1.5 hours.

[0057] 4) Pre-burning: Dry the raw materials that have been ball-milled once, and put them into an electric furnace for pre-burning. The pre-burning temperature is 1000°C, and the pre-burning time is 2 hours. After pre-burning, it is cooled with the furnace. After pre-burning, XRD phase analysis was carried out on the pre-fired material, and it was confirmed that only sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com