Silicon-based gallium nitride microwave millimeter wave transmission line with low electromagnetic loss and preparation method thereof

A silicon-based nitrogen, low-electromagnetic technology, applied in circuits, waveguides, electrical components, etc., can solve the problems of high electromagnetic loss, high background carrier concentration of microwave and millimeter-wave transmission lines, and limiting the performance of gallium nitride on silicon transmission lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

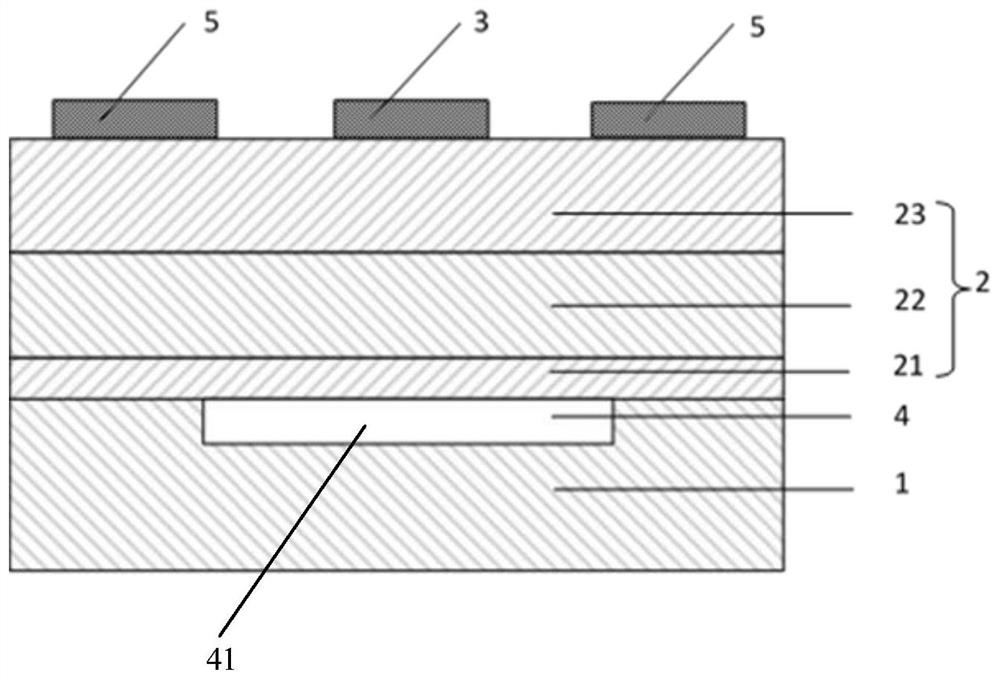

Embodiment 1

[0051] When Group III nitride materials including gallium nitride are epitaxially grown on a silicon substrate, aluminum atoms and gallium atoms will diffuse into the silicon substrate to form a p-type doped parasitic conductive channel. In addition, due to the existence of polarized charges in the III-nitride, an n-type inversion conduction channel exists at the silicon / nitride interface. These factors make the GaN-on-Si microwave and millimeter wave transmission line have high electromagnetic loss, which reduces the performance of the transmission line. At present, the main measures to suppress the electromagnetic loss of silicon-based GaN microwave and millimeter wave transmission lines are: 1. Optimize the thickness and growth conditions of the aluminum nitride nucleation layer, using a relatively thin aluminum nitride nucleation layer, but using a relatively thin The aluminum nitride nucleation layer will affect the quality of the subsequent transition layer of the III-ni...

Embodiment 2

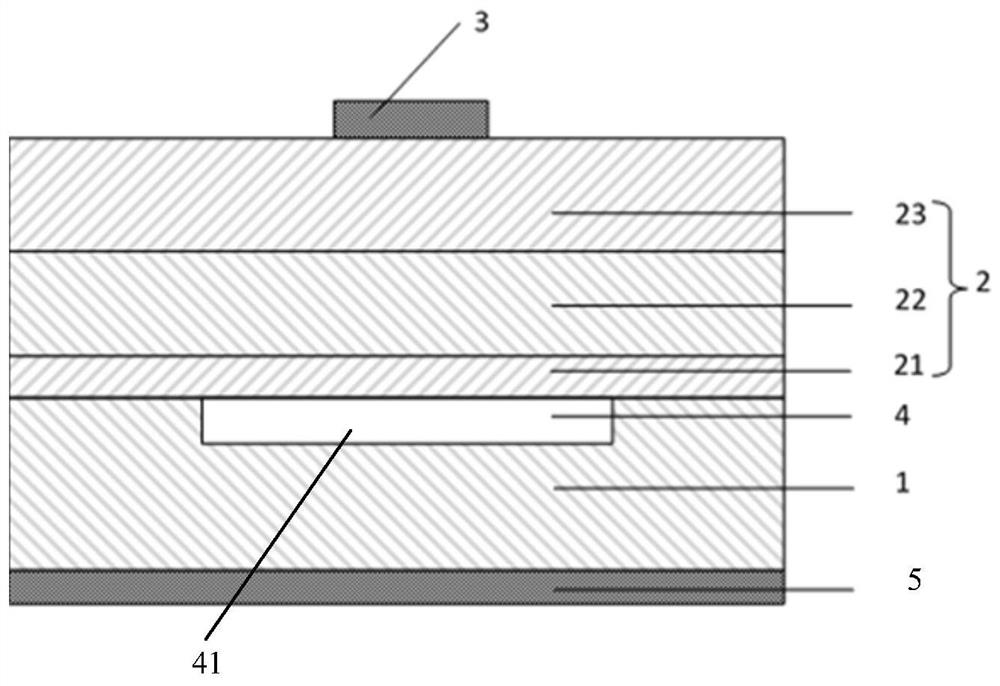

[0076] When Group III nitride materials including gallium nitride are epitaxially grown on a silicon substrate, except for the p-type doped channel on the surface of the silicon substrate and the silicon / aluminum nitride interface described in Embodiment 1 In addition to the influence of the n-type inversion channel on the electromagnetic loss of GaN-on-Si transmission line, the dislocation and defect density of the nucleation layer and the transition layer are relatively high, and the background impurity concentration is also relatively high, which will also bring a certain degree of Electromagnetic loss. The current main measures to suppress the electromagnetic loss of GaN-on-Si microwave and millimeter wave transmission lines described in Embodiment 1 have little effect on eliminating the electromagnetic loss of the nucleation layer and buffer layer, and also have the same effect as described in Embodiment 1. Shortcomings. Based on the above-mentioned problems, in order to...

Embodiment 3

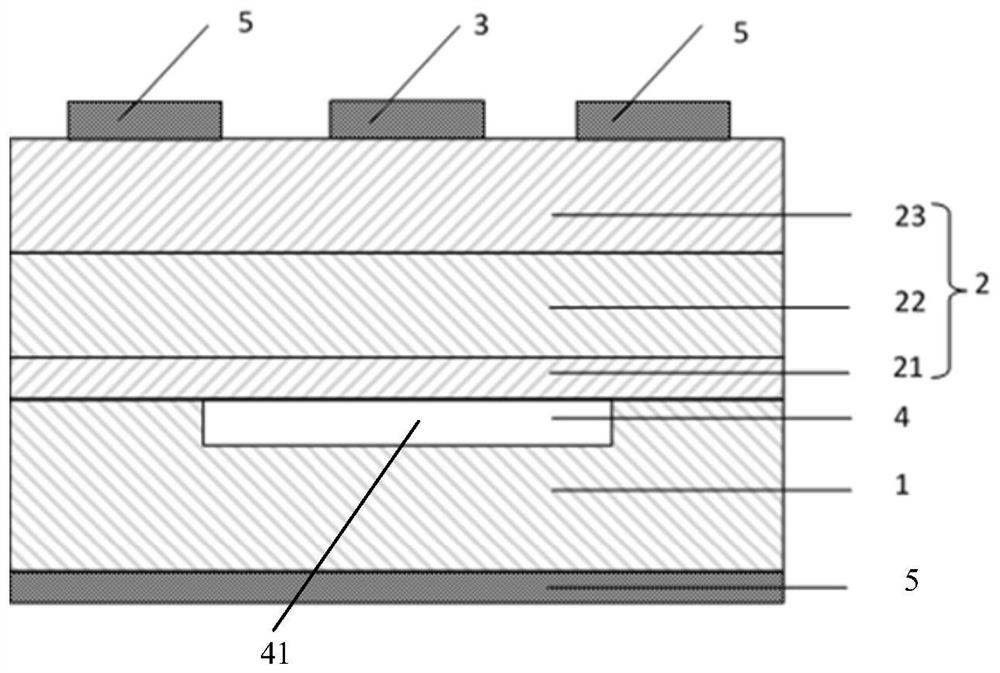

[0101] On the basis of the above embodiments, this embodiment provides a method for manufacturing a GaN-on-Si microwave and millimeter wave transmission line with low electromagnetic loss.

[0102] Described preparation method comprises:

[0103] S1: Select a silicon substrate;

[0104] S2: preparing a III-nitride epitaxial layer on the upper surface of the silicon substrate;

[0105] S3: Etching an internal cavity on the contact surface between the silicon substrate and the III-nitride epitaxial layer;

[0106] S4: preparing a high-frequency signal metal electrode on the upper surface of the III-nitride epitaxial layer;

[0107] S5: Prepare ground metal electrodes on both sides of the high-frequency signal metal electrodes and / or on the lower surface of the silicon substrate.

[0108] Further, said S2 includes:

[0109] S21: Prepare a nucleation layer with a thickness of 50nm-500nm on the upper surface of the silicon substrate by MOCVD equipment;

[0110] S22: Using MOCV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com