Cooling system and server system

A server system and cooling system technology, applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

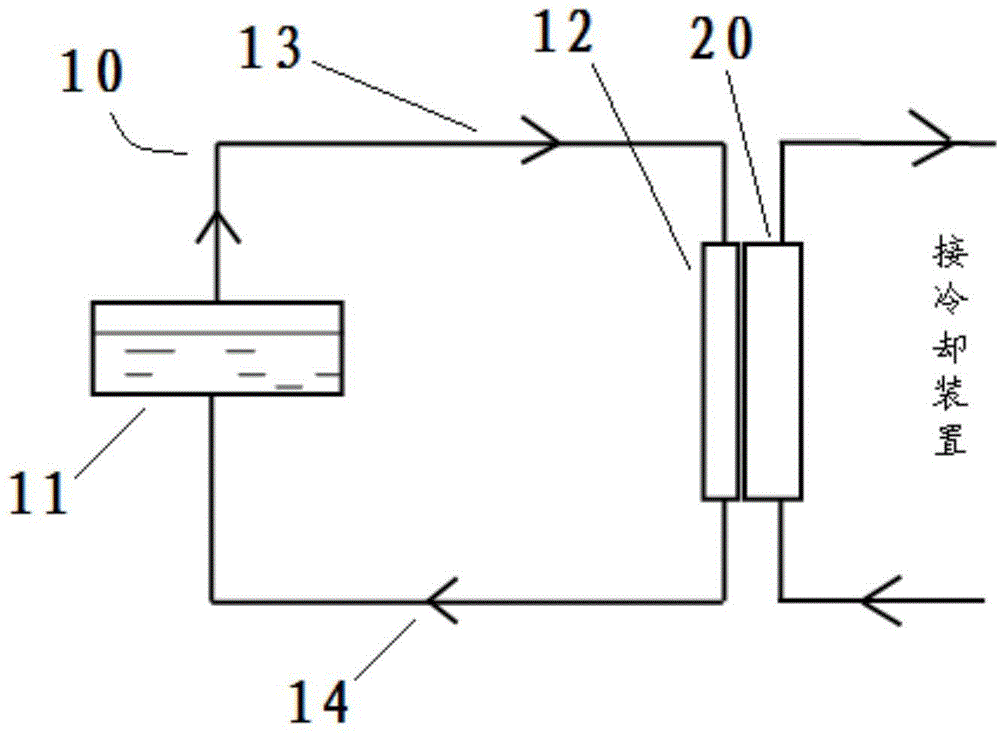

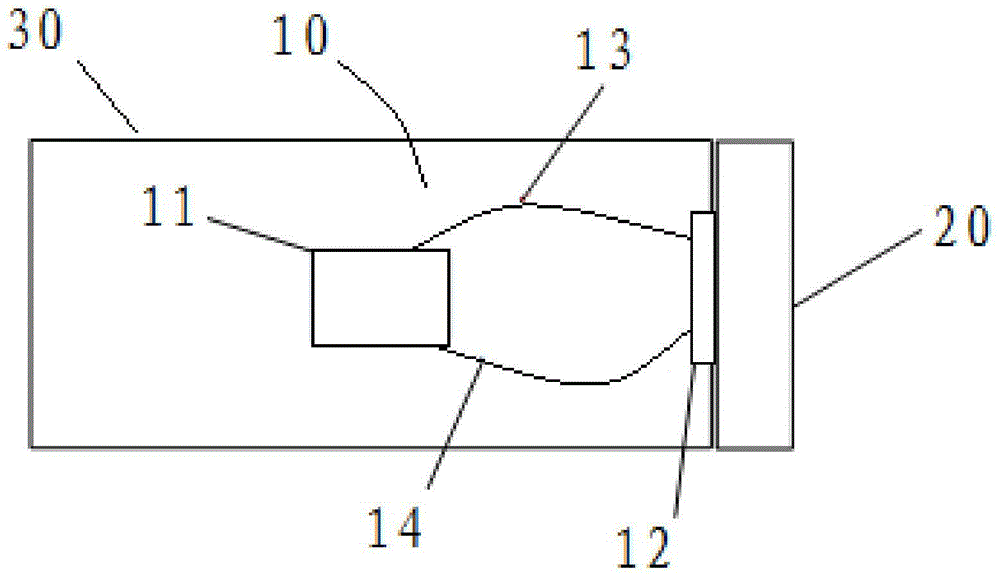

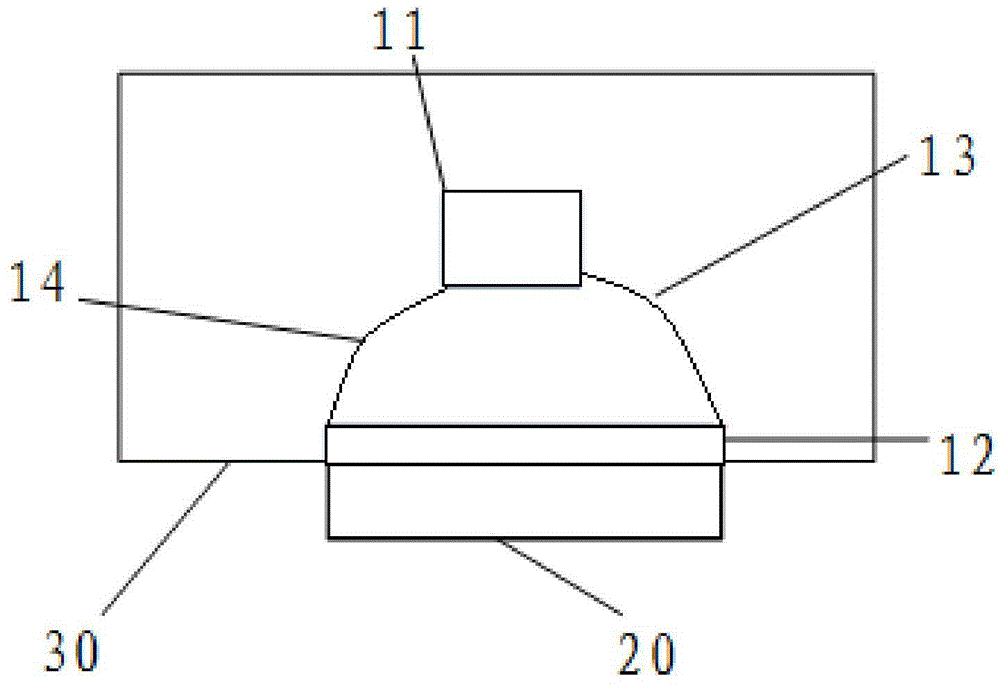

[0022] Now refer to Figure 1 to Figure 3 The cooling system and server system of the present invention will be described.

[0023] In the cooling system of the present invention, it includes a heat pipe 10 and a water cooling plate 20 . Specifically, the heat pipe 10 has a hot end 11, a liquid outlet pipe 13, a cold end 12, and a liquid inlet pipe 14, and the above-mentioned devices are sequentially connected end to end to form a cooling cycle, and the water cooling plate 20 is thermally coupled with the cold end 12 of the heat pipe 10. .

[0024] Specifically, in an optional embodiment, the cold end 12 can be in direct contact with the water cooling plate 20, so as to realize the above-mentioned thermal coupling in the form of direct contact; or, in another optional embodiment, the cold end 12 and the water-cooling plate 20 may be arranged at intervals in the form of heat exchange with each other, so as to realize the above-mentioned thermal coupling in the form of indirec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com