Fuse element

A technology of fuses and components, applied in the direction of electrical components, fuse manufacturing, capacitors, etc., can solve the problems of reduced ability to maintain voltage, reduced insulation length, increased fuse resistance, etc., to achieve reduced risk and reduced capacitor size , improve the effect of diversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

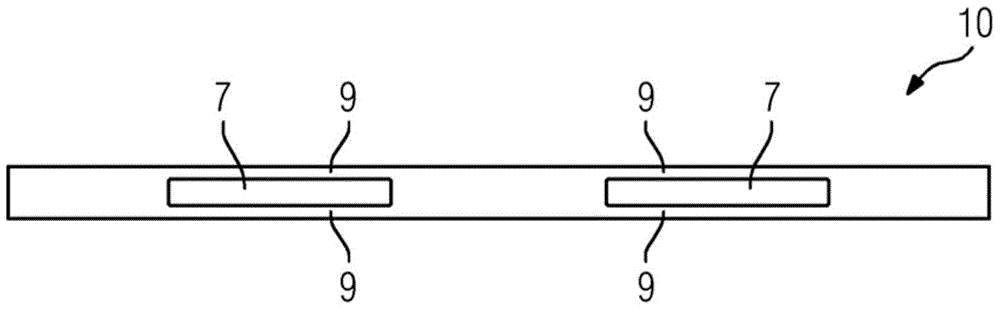

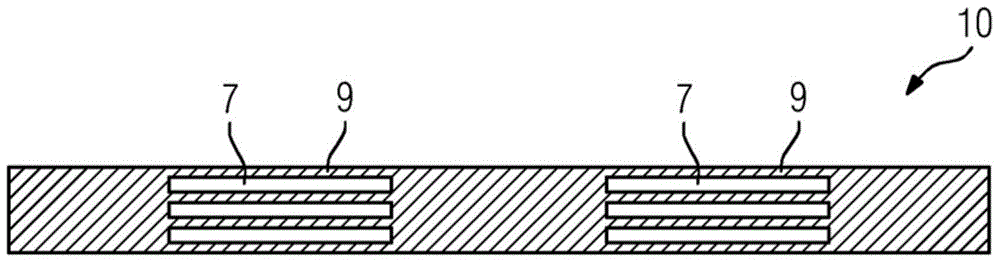

[0068] figure 1 An embodiment of a fuse element 10 according to the invention is shown. figure 1 Two elongated grooves 7 are shown forming four parallel metal sub-strips 9 of a straight fuse strip, which are respectively parallel to each other due to the grooves being located between the two sub-strips. The active responsive section produced by four parallel metal sub-strips 9 is formed on an elongated dielectric base layer made of polymeric material. The grooves 7 are aligned in series along the fuse metal layer. An elongated fuse metal layer is deposited on one side of the dielectric base layer, and an elongated groove 7 or opening is formed in an elongated fuse metal layer. The previously stated disadvantages of the conventional two-wire approach are overcome by the features of the present invention. The metal of the elongated fuse metal layer may be copper Cu. Alternatively, aluminum (Al), silver (Ag) or alloys thereof can be used as metal fuse material, which leads to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com