Novel and high-speed greening shrub pruning equipment

A pruning equipment, high-speed technology, applied to hedge trimming equipment, cutting equipment, gardening tools/equipment, etc., can solve the problems of heavy pruning workload, unsafe, high work intensity, etc., to increase the cutting area and achieve good performance. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

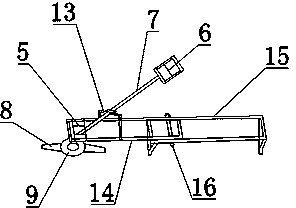

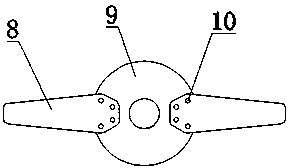

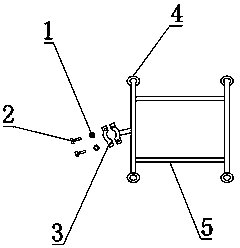

[0022] Such as figure 1 In the shown embodiment, a new type of high-speed greening shrub trimming equipment includes a trimming device, a horizontal fixing device, a vertical fixing device and a height adjustment device, and the trimming device includes a motor 6, a power transmission rod 7, a blade 8 and a flange 9, The motor 6, the power transmission rod 7 and the flange 9 are sequentially connected, the diameter of the flange 9 is 30cm, the blade 8 is symmetrically installed on the flange 9, the connection is provided with a fixing screw 10, and the trimming device is fixed and installed on a horizontal fixed On the device, the horizontal fixing device includes a fuselage mobile bracket 5, a fuselage support frame 13 and a horizontal mobile bracket 14, bearings 4 are respectively installed at the four corners of the fuselage mobile bracket 5, and a clamp A3 is welded on one side of the fuselage mobile bracket 5 , the hoop A3 is connected to the side of the power transmissio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com