Method for removing aflatoxin in plant raw material

A technology of aflatoxin and plant raw materials, applied in food science, application, food preparation, etc., can solve problems such as nutrient loss, achieve good degradation effect, high application value and market potential, and simple process

Inactive Publication Date: 2015-05-06

OCEAN UNIV OF CHINA

View PDF2 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Obviously, the heating method is easy to lose the nutrition of the material, and requires high-pressure resistant equipment

Biological method is also commonly used to remove aflatoxin. Lactic acid bacteria are safe strains. There is no report on the use of lactic acid bacteria for anaerobic solid-state fermentation to remove aflatoxin.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0020] 1.1 Materials

[0021] Dried peanut meal (Luhua Group); lactic acid bacteria were strains preserved in the laboratory; standard products of aflatoxin B1 and aflatoxin G1 were purchased from Sigma Chemicals (USA); lactic acid bacteria were cultured in MRS liquid medium; anaerobic tanks were purchased from Mitsubishi Gas Chemical CO., Inc. Japan.

[0022] 1.2 Aflatoxin removal experiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

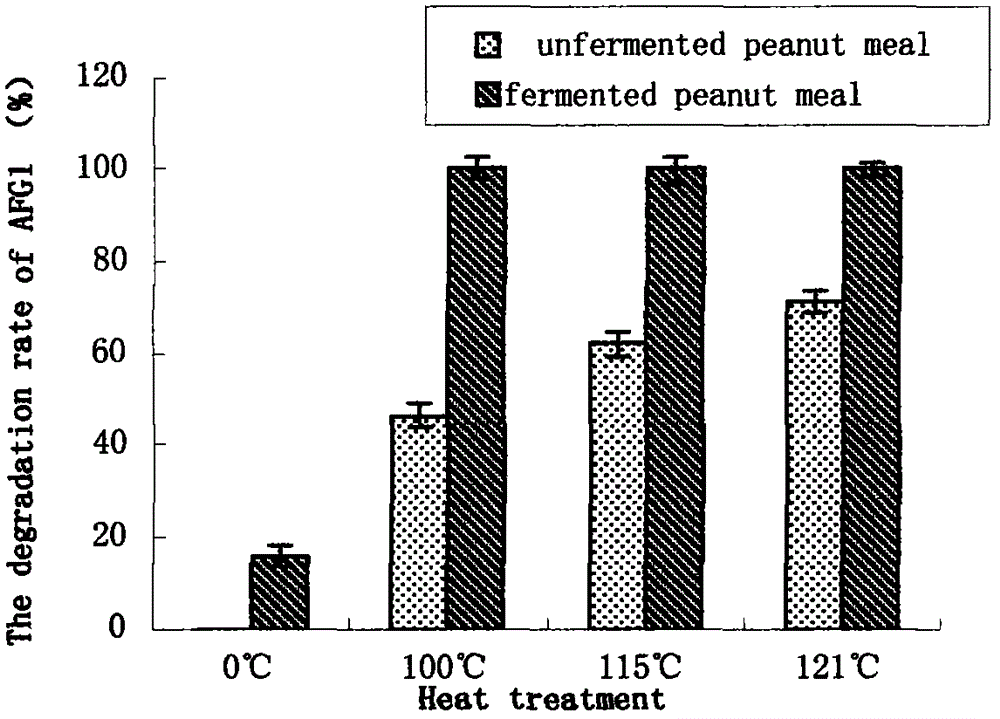

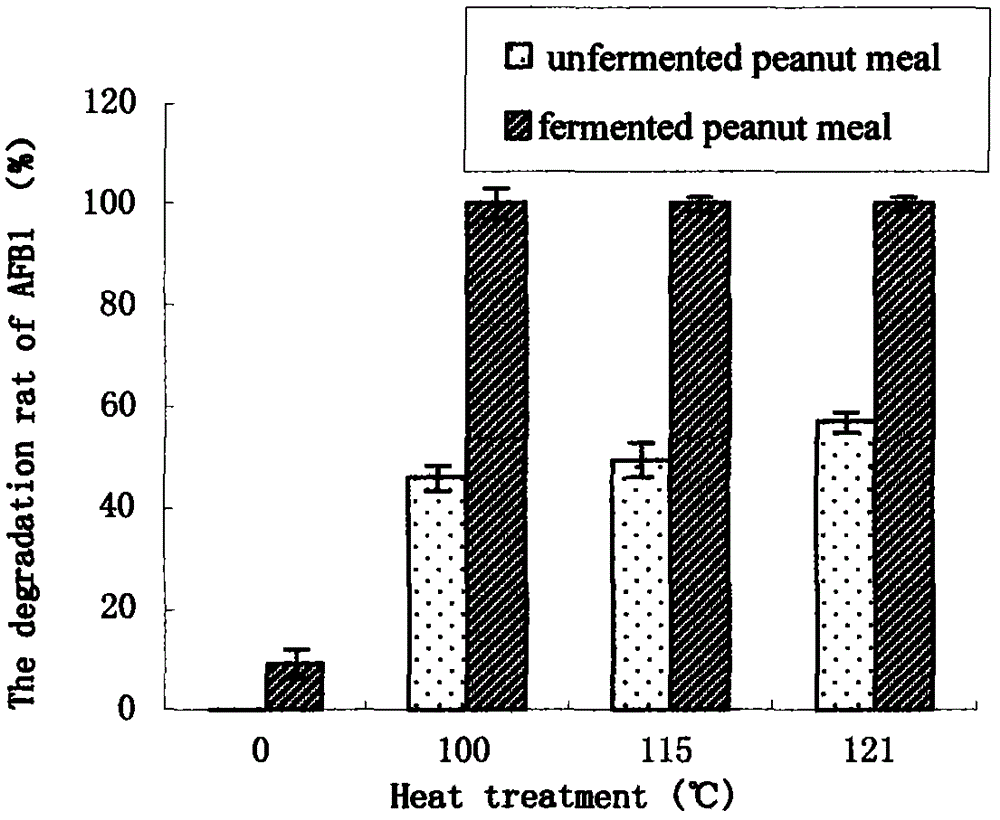

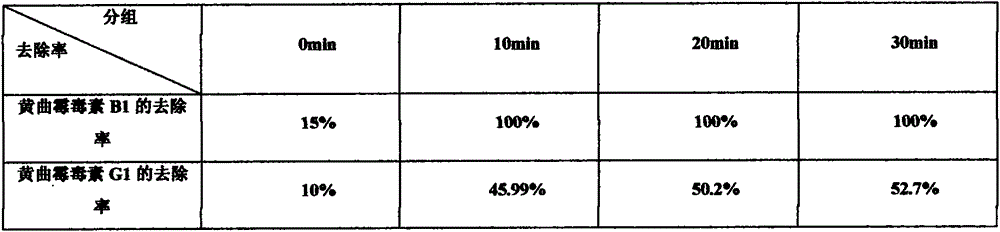

The invention relates to a method for removing aflatoxin in a plant raw material. The method comprises the following steps: adjusting pH of the plant raw material to be alkaline, inoculating a lactic acid bacteria culture solution to an alkaline plant raw material, carrying out anaerobic solid fermentation on the inoculated plant raw material to remove the aflatoxin in the plant raw material, finally detecting the content of aflatoxin by using a high-pressure liquid chromatography. According to the method, the conventional process of removing the aflatoxin in the plant raw material is changed; an anaerobic solid fermentation method is adopted; the aflatoxin in the plant raw material is greatly removed; in addition, the method is simple in process, good in degradation effect and suitable for degradation of the peanut meal aflatoxin; the removal rate of aflatoxin B1 reaches 100%; the method is high in application value and market potential.

Description

technical field [0001] The invention relates to a method for removing aflatoxin from plant raw materials. Background technique [0002] Aflatoxins are mainly produced by Aspergillus flavus and Aspergillus parasiticus, which are highly toxic, teratogenic and carcinogenic. Crops such as peanuts, corn, rice, cottonseed, and nuts are easily contaminated by aflatoxins. Aflatoxin B1 is the most toxic natural carcinogen known, which mainly causes liver cancer. [0003] Peanut meal is a by-product of the oil extraction process, which contains a lot of protein and is mainly used as feed in our country. However, peanut meal is also easily contaminated by aflatoxin, so the safety of peanut meal has also received great attention. There is an urgent need for a safe method to remove aflatoxin from peanut meal. Physical, chemical and biological methods are commonly used to remove aflatoxin from raw materials. Physical methods such as heating, adsorption, extraction, gamma ray irradiatio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23L1/015A23L5/20

Inventor 孔青陈玉洁单世华

Owner OCEAN UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com