Method for processing small packaged pork elaborately

A technology of fine processing and small packaging, applied in the fields of food preservation, food preparation, food science, etc., it can solve the problems of repeated pollution, air pollution, laborious thawing after eating again, and achieve the same taste and nutrition as fresh meat, quick freezing The effect of low temperature and short freezing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of pork fine processing small packaging method, its steps are as follows:

[0022] 1. Acid discharge treatment

[0023] Put the slaughtered white strip pollution-free pork into the low-temperature aseptic workshop to cool and discharge acid;

[0024] 2. Split

[0025] Put the white striped pork that has undergone acid discharge treatment on the assembly line, and divide it into front section, middle section, back section, ribs, and streaky pork according to the parts;

[0026] 3. Fine processing

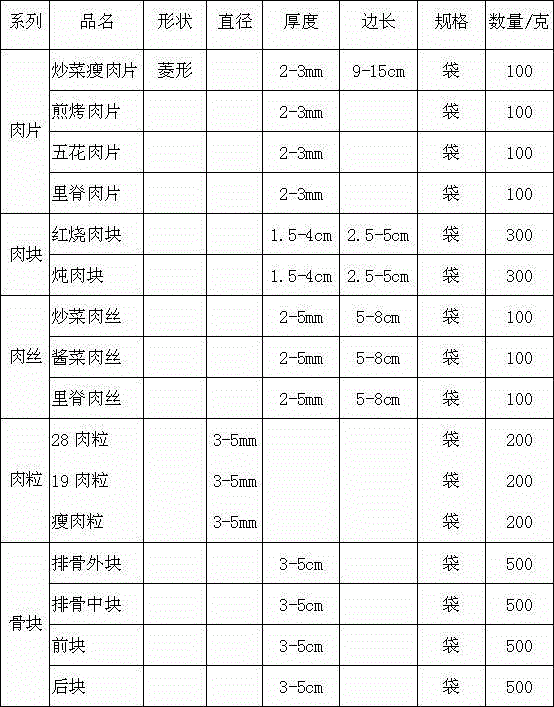

[0027] Using the automated mechanical assembly line, the divided meat pieces are finely divided into small parts, and then enter the slicer, dicing machine, shredding machine, granulator and bone cutter into the following forms (see Table 1):

[0028] Table 1

[0029]

[0030] 4. Quick freezing treatment

[0031] Use the ultra-low temperature air freezer at -80°C for quick freezing, and the quick freezing effect can be achieved within 30 seconds;

[0032] 5. Pa...

Embodiment 2

[0035] A kind of pork fine processing small packaging method, its steps are as follows:

[0036] 1. Acid discharge treatment

[0037] Put the slaughtered white strip pollution-free pork into the low-temperature aseptic workshop to cool and discharge acid;

[0038] 2. Split

[0039] Put the white striped pork that has undergone acid discharge treatment on the assembly line, and divide it into front section, middle section, back section, ribs, and streaky pork according to the parts;

[0040] 3. Fine processing

[0041] Using the automated mechanical assembly line, the divided meat pieces are finely divided into small parts, and then enter the slicer, dicing machine, shredding machine, granulator and bone cutter into the following forms (see Table 1):

[0042] 4. Quick freezing treatment

[0043] Use the ultra-low temperature air freezer at -120°C for quick freezing, and the quick freezing effect can be achieved within 20 seconds;

[0044] 5. Packaging

[0045] Sterilized ...

Embodiment 3

[0047] A kind of pork fine processing small packaging method, its steps are as follows:

[0048] 1. Acid discharge treatment

[0049] Put the slaughtered white strip pollution-free pork into the low-temperature aseptic workshop to cool and discharge acid;

[0050] 2. Split

[0051] Put the white striped pork that has undergone acid discharge treatment on the assembly line, and divide it into front section, middle section, back section, ribs, and streaky pork according to the parts;

[0052] 3. Fine processing

[0053] Using the automated mechanical assembly line, the divided meat pieces are finely divided into small parts of meat, and then enter the slicer, dicing machine, shredder, granulator and bone cutter into the following forms, as shown in Table 1:

[0054] 4. Quick freezing treatment

[0055] Use the ultra-low temperature air freezer at -100°C for quick freezing, and the quick freezing effect can be achieved within 25 seconds;

[0056] 5. Packaging

[0057] Steri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com