Annular gap-type centrifugal extractor with vertical mixed baffle

A mixing baffle and annular gap technology, which is applied in the direction of liquid solution solvent extraction, etc., can solve the problem of insufficient mixing of two-phase liquids, and achieve the effects of improving mass transfer efficiency, strengthening mixing intensity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

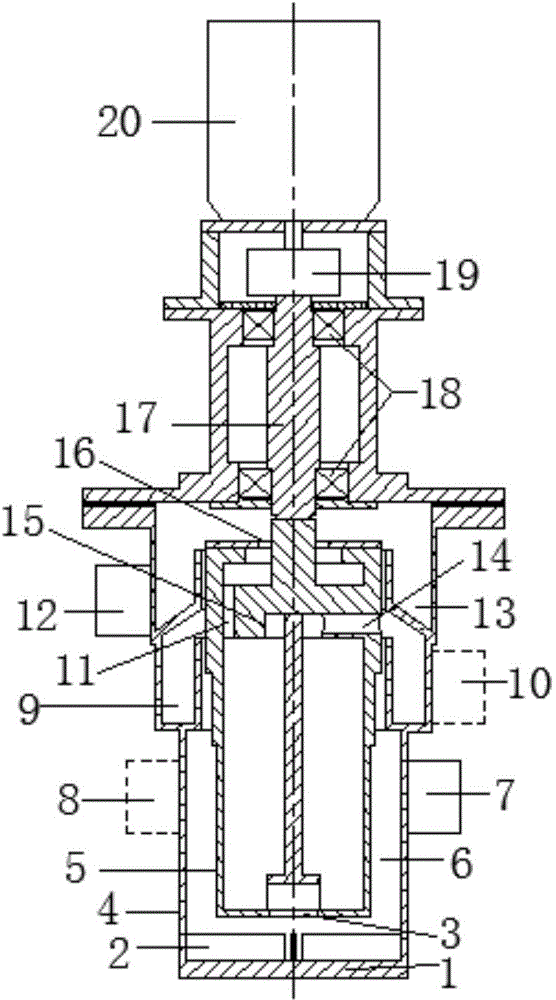

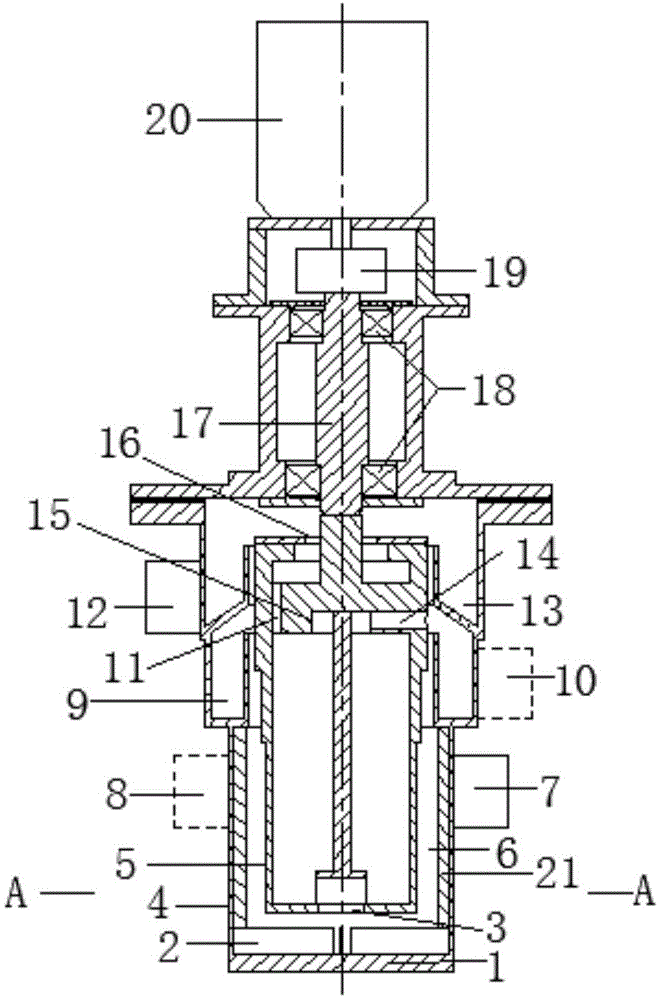

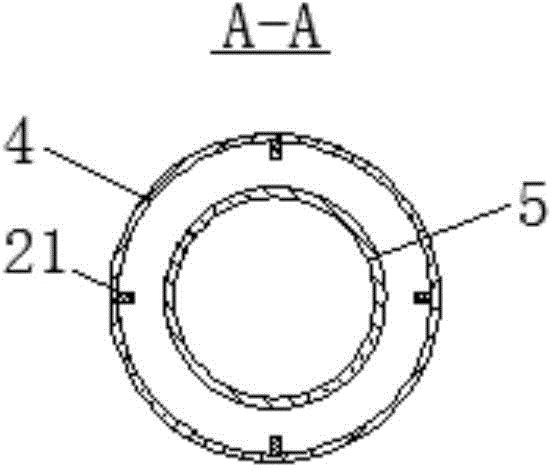

[0019] The existing annular gap centrifugal extractor with a drum diameter of 10 mm is adopted, and the annular gap centrifugal extractor mainly includes a fixed blade 2, a casing 4, a drum 5, a light phase inlet pipe 7, a heavy phase inlet pipe 8, Light phase collecting ring 9, light phase outlet pipe 10, heavy phase vertical channel 11, heavy phase outlet pipe 12, heavy phase collecting ring 13, light phase horizontal channel 14, light phase weir 15, heavy phase weir 16, main shaft 17, bearing 18. The shaft coupling 19 and the motor 20, wherein the inner wall of the lower section of the housing is smooth; the present invention adopts an annular gap type centrifugal extractor with a drum diameter of 10 mm. In addition to the above-mentioned structure, it is manufactured by wire cutting. Four vertical mixing baffles 21 are evenly arranged on the inner wall of the lower section of the shell, and the size in the radial direction is 1 mm, and the size in the circumferential direct...

Embodiment 2

[0021] At present, an annular gap type centrifugal extractor with a drum diameter of 70 mm mainly includes fixed blades 2, a casing 4, a drum 5, a light phase inlet pipe 7, a heavy phase inlet pipe 8, a light phase collection ring 9, a light phase Outlet pipe 10, heavy phase vertical channel 11, heavy phase outlet pipe 12, heavy phase collecting ring 13, light phase horizontal channel 14, light phase weir 15, heavy phase weir 16, main shaft 17, bearing 18, coupling 19 and motor 20, wherein the inner wall of the lower section of the shell is smooth; the new annular gap centrifugal extractor with a drum diameter of 70mm includes the above-mentioned structure, and is evenly distributed on the inner wall of the lower section of the shell 4 by means of welding. A vertical mixing baffle 21, the dimension in the radial direction is 4mm, the dimension in the circumferential direction is 2mm (that is, the radial thickness is 4mm, and the circumferential width is 2mm), and the height is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com