Oil well thermal cleaning filter

A filtration device and hot washing technology, applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of high manufacturing and use costs, complex design, difficulty, etc., and achieve easy individual control and device design. Reasonable and easy to promote and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical solution of the present invention clearer, the present invention will be further described below with examples in conjunction with the accompanying drawings.

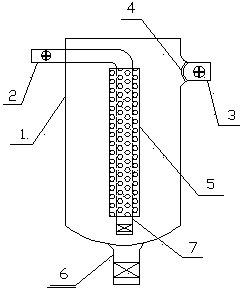

[0014] Depend on figure 1 It can be seen that a kind of oil well hot washing filtering device includes a tank body 1, and the tank body 1 is provided with a water inlet pipe 2, a drain pipe 3 and a sewage discharge pipe 6, and the drain pipe 3 is connected to the oil well hot washing water injection pipe, and the water inlet pipe 2 is connected by the side of the tank body. The upper part of the wall extends horizontally into the center of the inner cavity of the tank and bends toward the bottom of the tank to form a vertical section. The vertical section is provided with a section of water outlet filter element 5 from inside to outside. The bottom of the water outlet filter element 5 is the impurity precipitation section 7 of the water inlet pipe. 1 There are 6 outlets for sewage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com