Ferrite cleaning and baking equipment and realization method thereof

A technology of drying equipment and realization method, applied in the direction of using liquid cleaning method, cleaning method and utensils, drying, etc., can solve the problem of insufficient drying of ferrite products, unclean ferrite products, and downstream processes. Problems such as long process operation time, to achieve the effect of simple structure, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

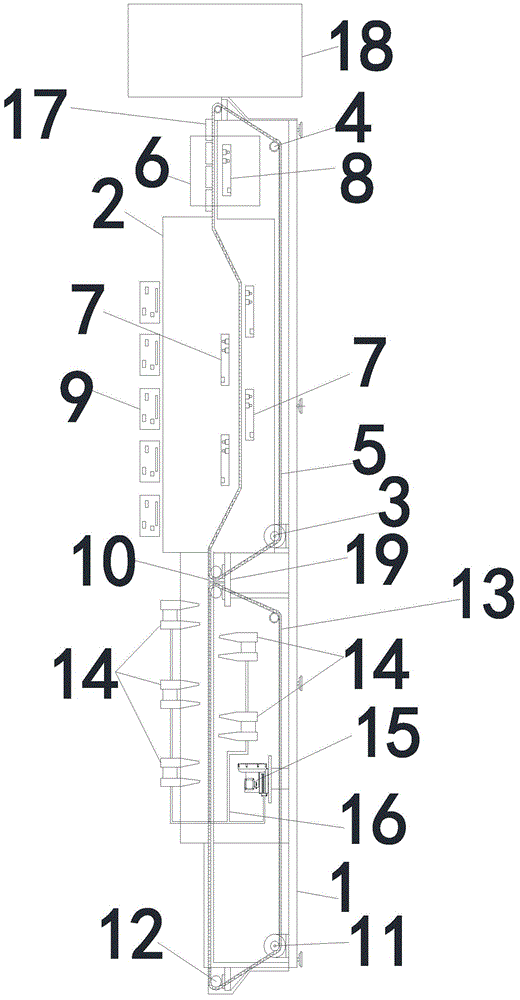

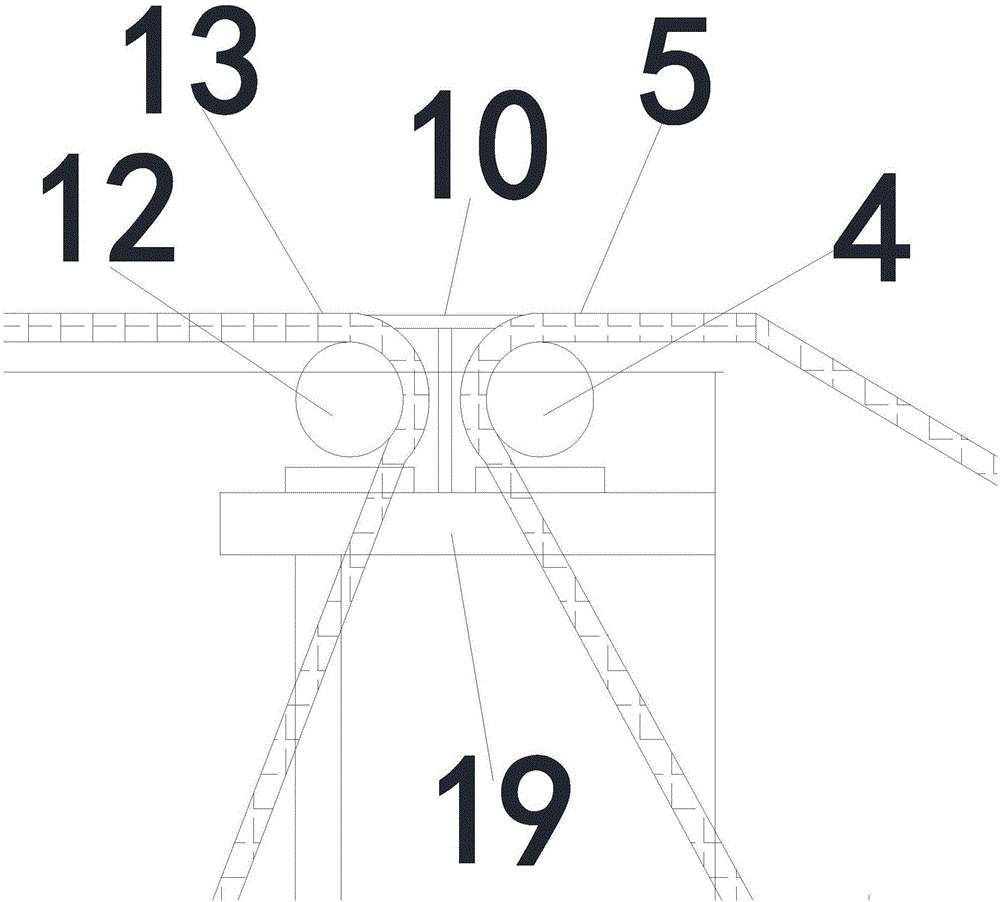

[0045] Such as Figure 1~3As shown, a ferrite cleaning and drying equipment includes an equipment support 1, a first water tank 2 is arranged on the equipment support 1, a first motor 3 is arranged under the first water tank 2, and the first motor 3 passes through several first transition wheels 4 drives the first mesh belt 5 to move. In the present embodiment, there are multiple first transition wheels 4. The inlet end of the first water tank 2 is provided with a second water tank 6. The first mesh belt 5 drives the product 17 to pass through the second water tank 6 and The first water tank 2, the first water tank 2 and the second water tank are independent of each other 6, the first vibrator 7 is set in the first water tank 2, a number of second vibrators 8 are set in the second water tank 6, and the vibrator 9 is connected to the first vibrator 7 And the second vibrator 8, in the present embodiment, there are 5 vibrator 9, which are respectively connected to a vibrator; the...

Embodiment 2

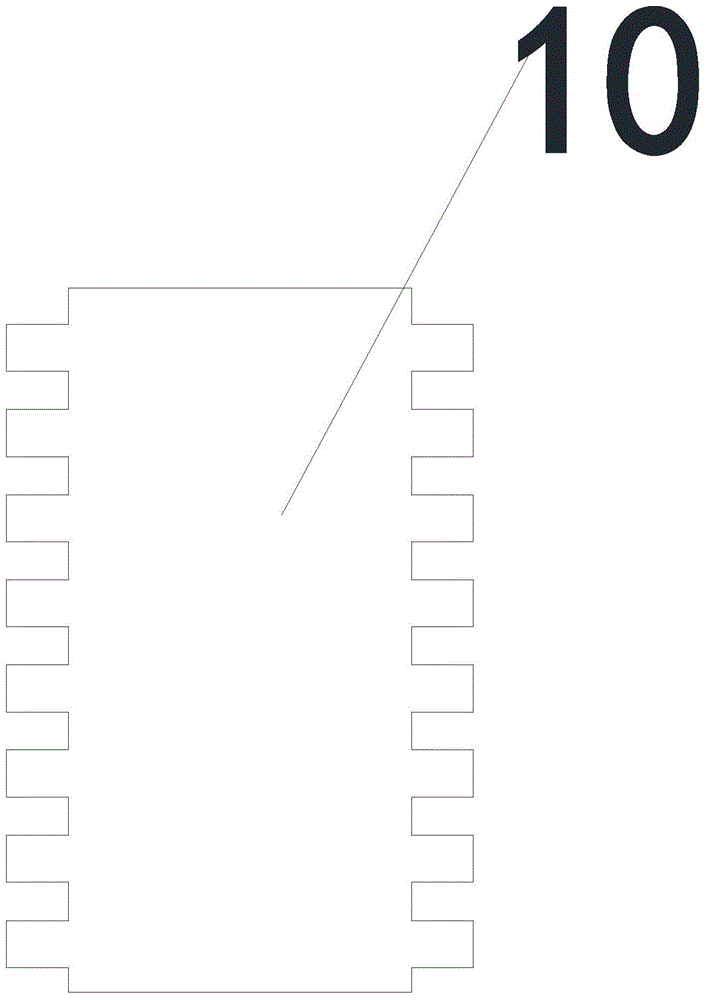

[0061] The difference between the present embodiment and Embodiment 1 is that the distance between the air knife 14 in the present embodiment and the second mesh belt 13 is 65mm, and the distance between the air knife 14 in each group is 200mm. The distance is 800mm; Transition device comprises transition device support 19, and transition device support 19 is located on equipment support 1, and transition device support 19 intermediate positions are provided with roller group (this is the transition plate 10 of this embodiment), and purpose is to make The product 17 in front can be pushed onto the second mesh belt 13 with very little force, and the structure is simple and easy to maintain; the impurity removal rate of rough cleaning is 80%; the impurity removal rate of fine cleaning is 99.5%.

[0062] In this embodiment, both the first water tank 2 and the second water tank 6 are provided with water inlet pipes and water outlet pipes; the water inlet pipes are provided with sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com