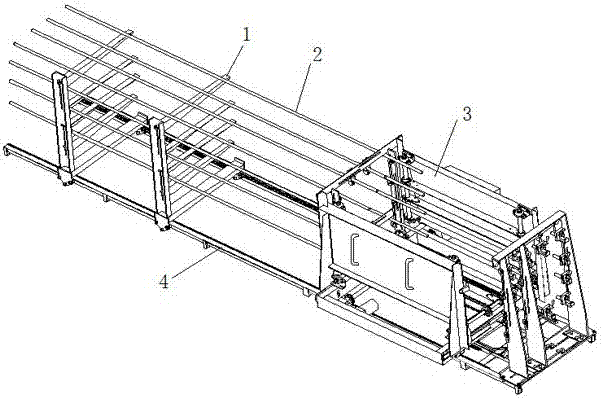

Variable spiral continuous stirrup reinforcement frame machine can adjust the longitudinal reinforcement bracket

A steel skeleton and variable helix technology, which is applied in the field of support and adjustment devices for the longitudinal reinforcement of the stirrup box of the steel skeleton forming machine, can solve problems such as drooping deformation, force deviation, and affecting the quality of the steel skeleton forming, and achieve effective support and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

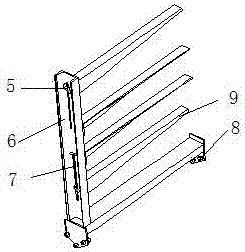

[0022] Embodiment one: if figure 2 As shown, the bracket is composed of a walking frame 6, which is provided with a walking wheel 8 that cooperates with a steel frame machine track 4 to form a mobile pair and four forks 9 for supporting the longitudinal ribs 2. Walking frame 6 is L-shaped, and the vertical limit of walking frame 6 is connected with supporting fork 9, and the horizontal limit two ends are connected with walking wheel 8. The supporting fork 9 is a variable section type, and the cross-sectional size decreases progressively from the near walking frame end to the far walking frame end. The walking frame 6 is also provided with two slideways 7. According to the layout requirements of the longitudinal ribs 2, adjust the position of the support fork 9 on the slideway 7, and then use the bolt 5 to fix the support fork 9 on the walking frame 6. The upper surface of the support fork 9 in contact with the longitudinal rib 2 is parallel to the horizontal side of the walk...

Embodiment 2

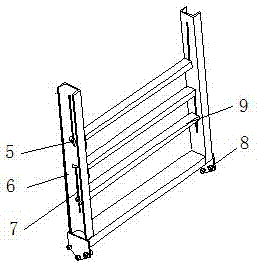

[0023] Embodiment two: if image 3 As shown, the bracket 1 is composed of a walking frame 6, on which the walking wheel 8 and the three supporting forks 9 for supporting the longitudinal reinforcement 2 are arranged to cooperate with the steel frame machine track 4 to form a moving pair. The walking frame 6 is U-shaped, and the two symmetrical vertical sides of the walking frame 6 are respectively connected with the two ends of the support fork 9, and the two ends of the horizontal side are connected with the walking wheels 8. Support fork 9 is equal section type. Walking frame 6 is provided with a slideway 7, adjusts the position of support fork 9 on slideway 7 and is fixed on the walking frame 6 by bolt 5. The upper surface of the support fork 9 in contact with the longitudinal rib 2 is parallel to the horizontal side of the walking frame 6 .

[0024] After the bracket 1 is arranged on the track 4 of the steel frame machine, arrange the longitudinal ribs 2 as required, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com