Spark plasma sintering manufacturing process of high hardness polycrystalline diamond wire drawing die

A technology of polycrystalline diamond and discharge plasma, which is applied in the field of wire drawing dies, can solve problems such as shortening sintering time, achieve the effects of shortening sintering time, increasing wear resistance, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

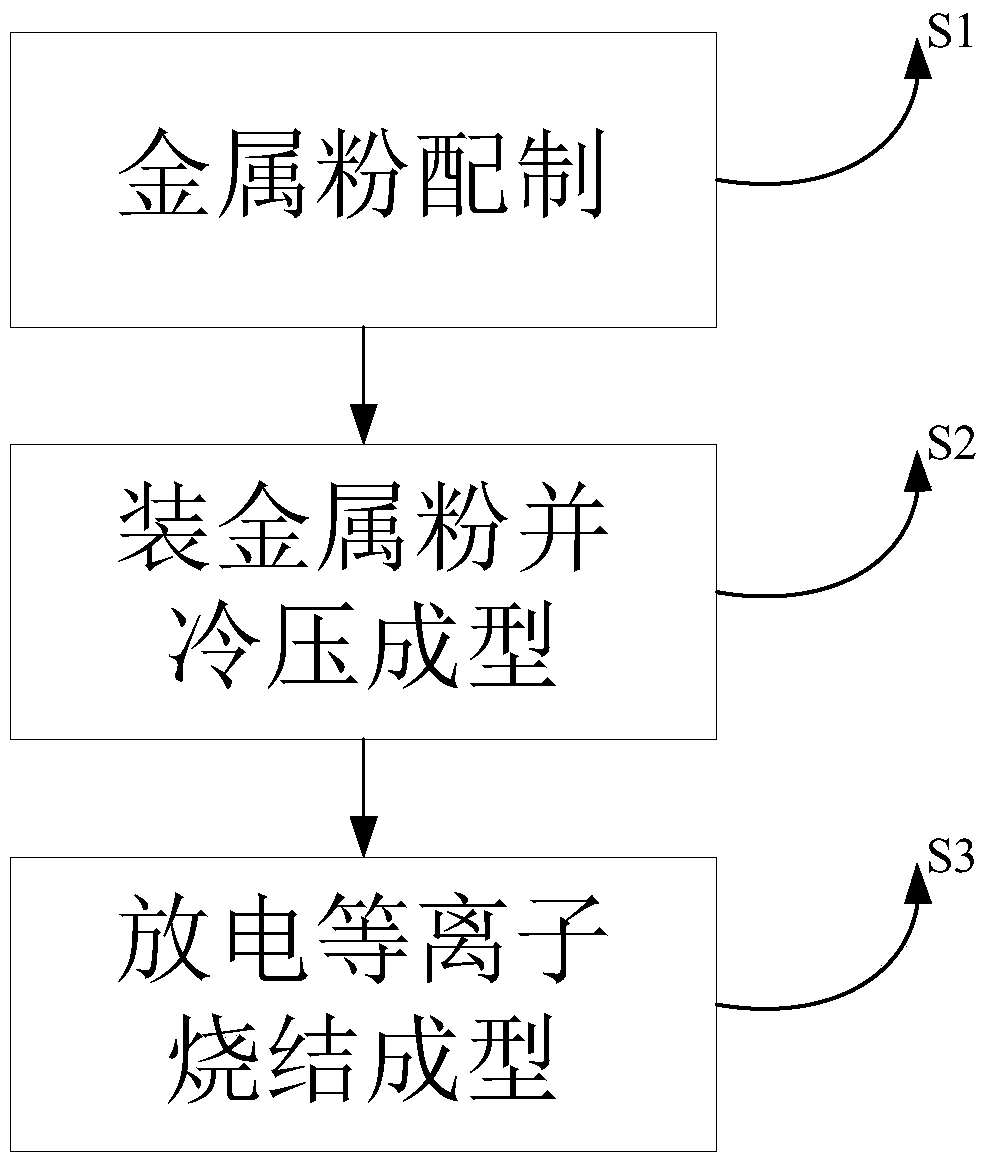

[0030] S1. Mix the metal powders evenly according to the mass proportion listed in Example 1 in Table 1;

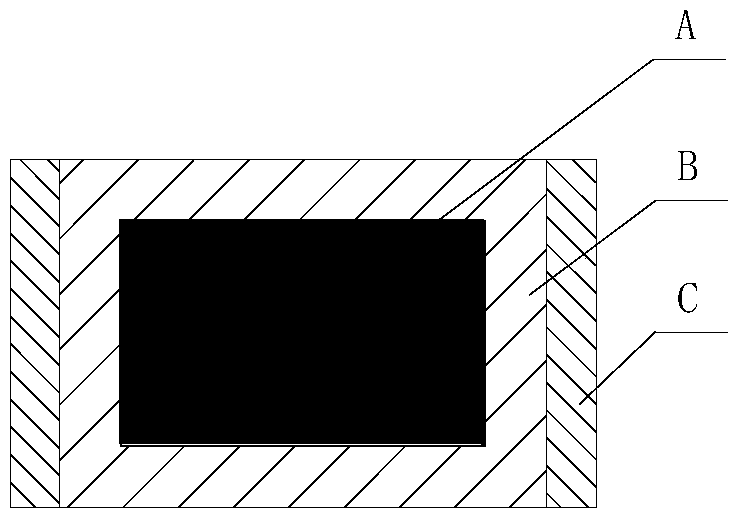

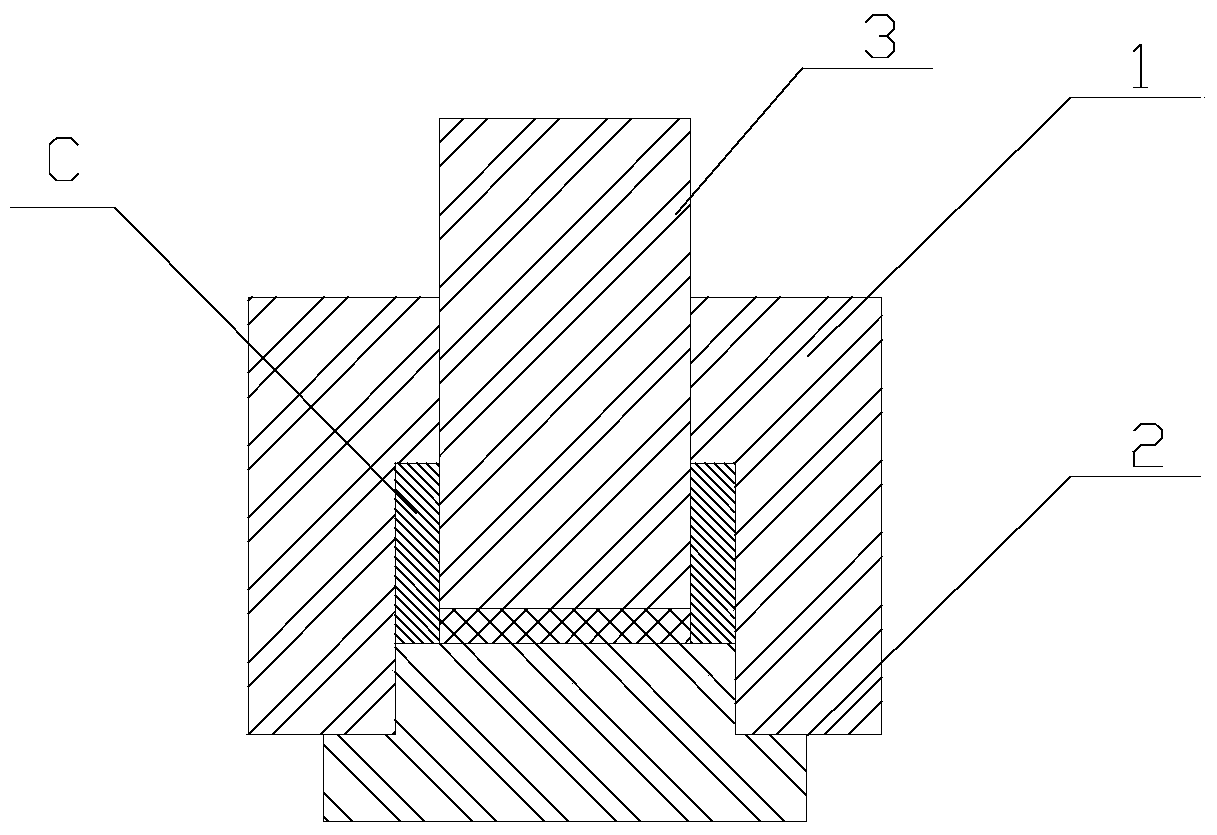

[0031] S2, place the steel sleeve in the lower cavity of the upper die 1, and then place the cylinder of the lower die 2 in the lower cavity of the upper die 1, so that the steel sleeve is installed between the upper die 1 and the lower die 2; weigh A The metal powder prepared in unit S1 is poured into the steel sleeve, the graphite mold is vibrated to make the metal powder even and smooth, and the graphite pressure column is inserted into the upper mold 1 from the upper cavity, as shown in image 3 As shown, the graphite pressing column presses the metal powder, and the combination of the upper mold 1, the lower mold 2, the steel sleeve, the metal powder and the graphite pressing column is put into the sintering machine, and the metal powder is compacted by cold pressing, and the compacted metal powder Form the bottom of the insert; stick the polycrystalline diamond mold...

Embodiment 2

[0036] S1, mix each metal powder evenly according to the mass proportion listed in Example 2 in Table 1;

[0037] S2, the steel sleeve is placed in the lower cavity of the upper mold 1, and then the cylinder of the lower mold 2 is placed in the lower cavity of the upper mold 1, so that the steel sleeve is installed between the upper mold 1 and the lower mold 2; The metal powder prepared in unit A S1 is poured into the steel sleeve, the graphite mold is vibrated to make the metal powder even and smooth, and the graphite pressure column is inserted into the upper mold 1 from the upper cavity, as shown image 3 As shown, the graphite pressing column presses the metal powder, and the combination of the upper mold 1, the lower mold 2, the steel sleeve, the metal powder and the graphite pressing column is put into the sintering machine, and the metal powder is compacted by cold pressing, and the compacted metal powder Form the bottom of the insert; stick the polycrystalline diamond ...

Embodiment 3

[0042] S1, mix each metal powder evenly according to the mass proportion listed in Example 3 in Table 1;

[0043] S2, the steel sleeve is placed in the lower cavity of the upper mold 1, and then the cylinder of the lower mold 2 is placed in the lower cavity of the upper mold 1, so that the steel sleeve is installed between the upper mold 1 and the lower mold 2; The metal powder prepared in unit A S1 is poured into the steel sleeve, the graphite mold is vibrated to make the metal powder even and smooth, and the graphite pressure column is inserted into the upper mold 1 from the upper cavity, as shown image 3 As shown, the graphite pressing column presses the metal powder, and the combination of the upper mold 1, the lower mold 2, the steel sleeve, the metal powder and the graphite pressing column is put into the sintering machine, and the metal powder is compacted by cold pressing, and the compacted metal powder Form the bottom of the insert; stick the polycrystalline diamond ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com