A rotary machining tool

A rotary machining and tool technology, applied in the field of metal cutting, can solve the problems of dovetail groove wear, reduced tool service life, damage, etc., and achieves good impact resistance, improved impact resistance, and stable and reliable positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

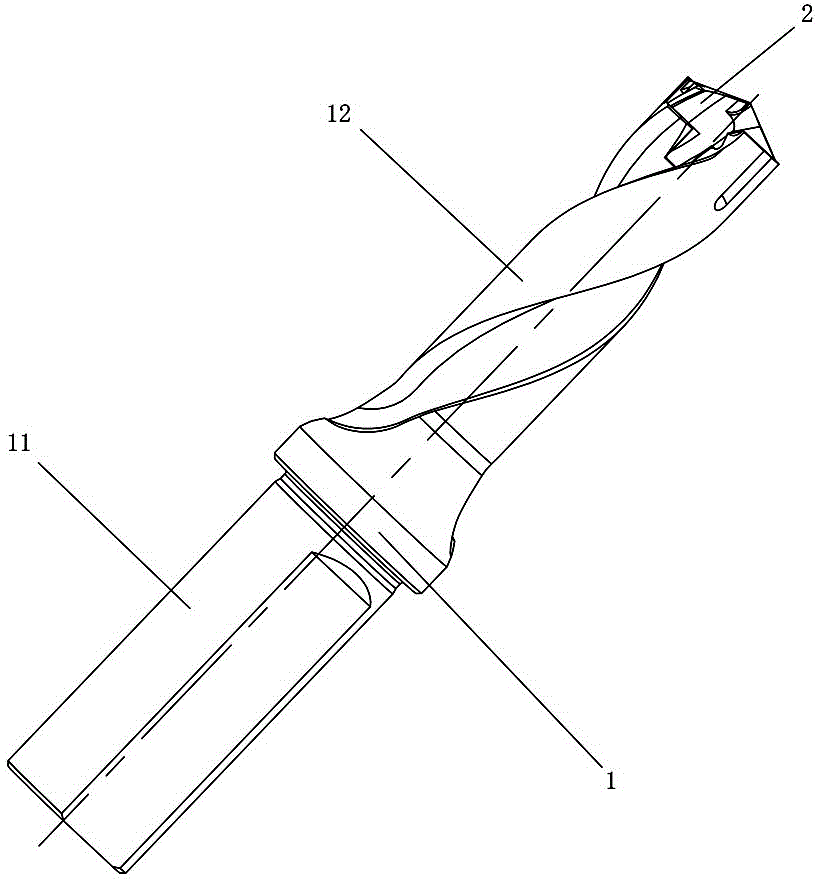

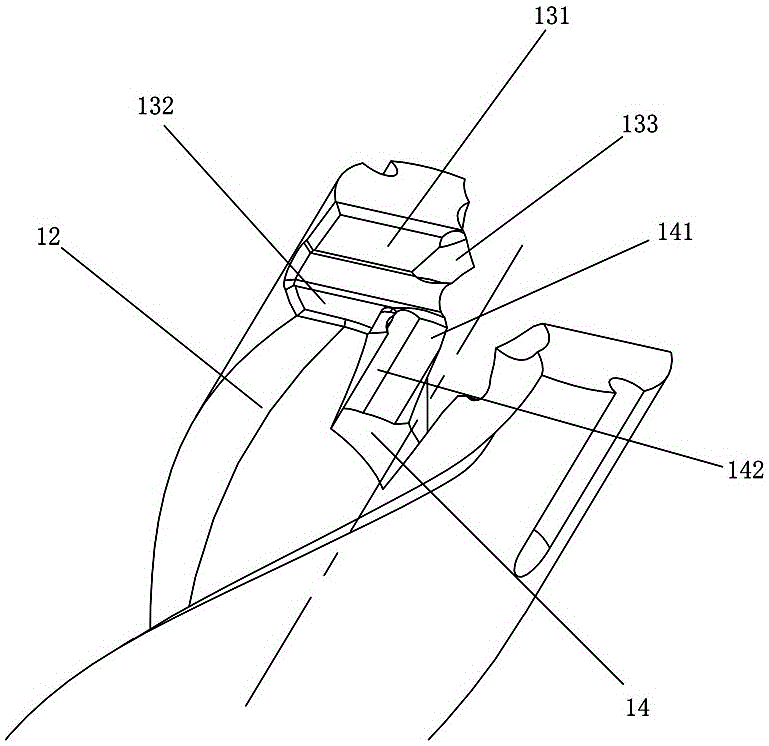

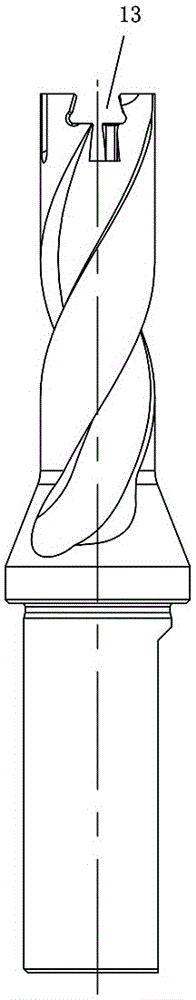

[0028] Figures 1 to 9 An embodiment of the rotary machining tool of the present invention is shown, including a clamping part 1 and a cutting part 2, the clamping part 1 includes a handle 11 and an elastic clamping part 12, and the cutting part 2 is installed on the elastic clamping part 12 Above, the cutting part 2 includes a cutting head 21 and a connecting portion 22. The cutting head 21 is provided with at least two cutting edges 211 and at least two inclined positioning surfaces 212. The inclined positioning surfaces 212 are along the cutting feed direction of the rotary processing tool. The axis of the rotary machining tool is inclined, the transition surface between the cutting head 21 and the connecting portion 22 forms an axial positioning surface 23, the elastic clamping portion 12 is provided with a dovetail groove 13, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com