Stretched diaphragm welding equipment for suspension diaphragm hollow glass

A welding equipment and glass technology, which is applied to the stretch film welding process and equipment field of suspended film insulating glass, can solve the problems such as difficulty in controlling the stretch film quality, restricting the production rhythm, etc., so as to reduce the effective working surface, reduce mutual interference, and improve the level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

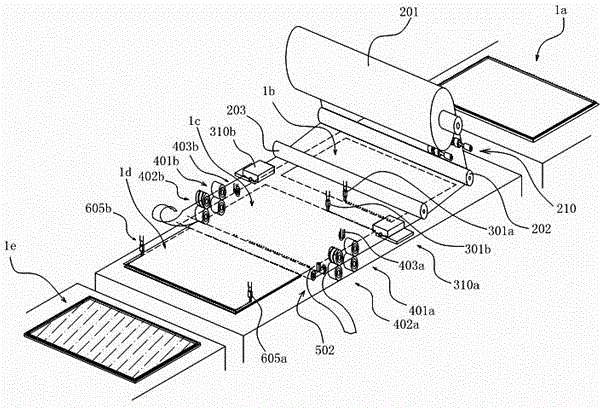

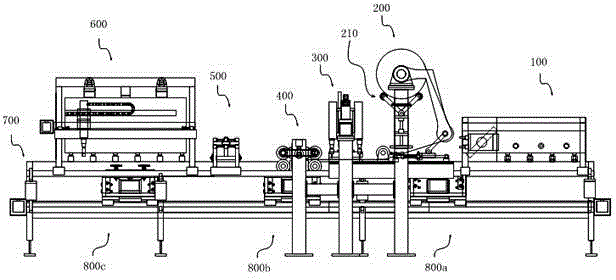

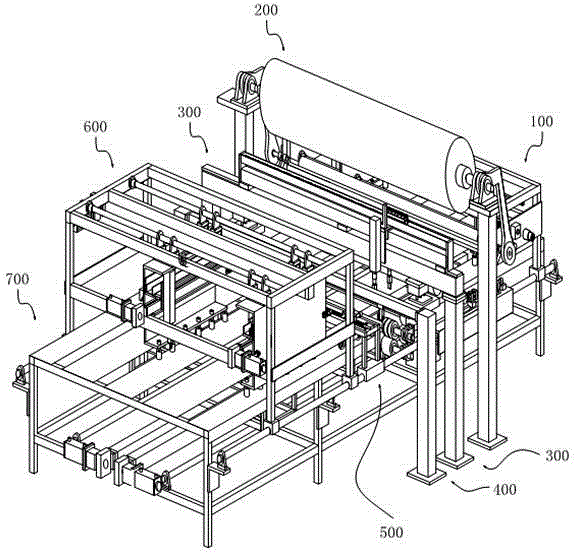

[0054] like figure 2 , 3 , 4 shows the stretch film welding equipment for the hanging film insulating glass provided by the present invention, wherein the structures of the hanging film insulating glass, the stretch film frame 4 and the elastic clip 3 are detailed in No. ZL201320644191.6 and Patent No. ZL201320644286.8.

[0055] The stretch film welding equipment includes: a positioning frame 100 to determine the working reference line, a film stretching mechanism 200 that sends out the film and stretches it and lays it horizontally on the stretch film edge of the stretch film frame, and connects two adjacent sides parallel to the film axis. The stretch film frame on the seam of the glass is welded at the same time and the film on this section is bidirectionally tensioned (referring to the direction of glass movement and perpendicular to the direction of glass movement). Rolling mechanism 400 that cuts off the excess film on both sides along the horizontal edge of the glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com