A paper bowl creasing and cutting machine

A technology of cutting machine and creasing machine, applied in the direction of cardboard articles, etc., can solve the problems of easy deformation, high work intensity, low production efficiency, etc., to improve cutting accuracy, improve cutting accuracy, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

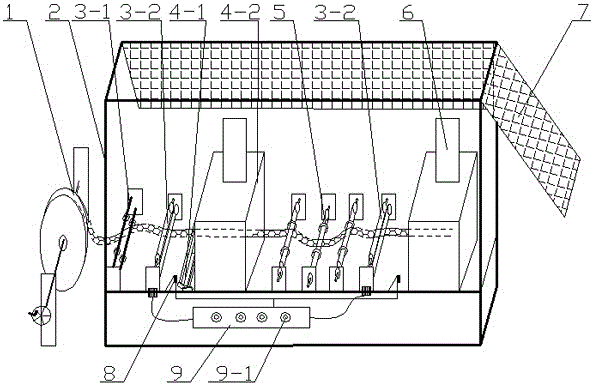

[0036] refer to figure 1 , a paper bowl creasing and cutting machine, including a paper feeding mechanism 1 and a frame 2, and the frame 2 is also provided with a protective net 7, which can reduce equipment damage when the paper bowl creasing and cutting machine is used rate, and prevent staff from being injured due to equipment failure; the paper feeding mechanism 1 is installed on the left side of the frame 2, and provides paper for paper bowl processing to the paper feeding mechanism;

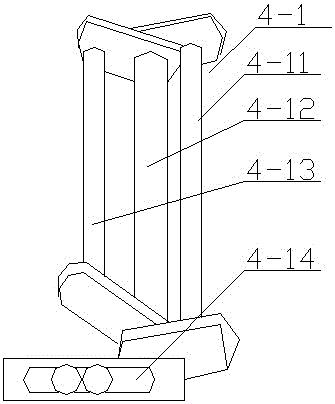

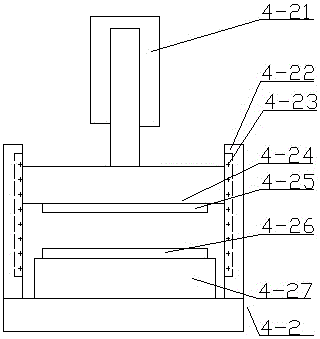

[0037] The creasing machine, installed on the frame 2, is used to stamp the periphery of the paper used for paper bowl processing and form anti-skid lines;

[0038] Cutting machine 6, cutting the paper processed by the creasing machine into circular paper sheets;

[0039] The center alignment device adjusts the center position of the paper processed by the creasing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com