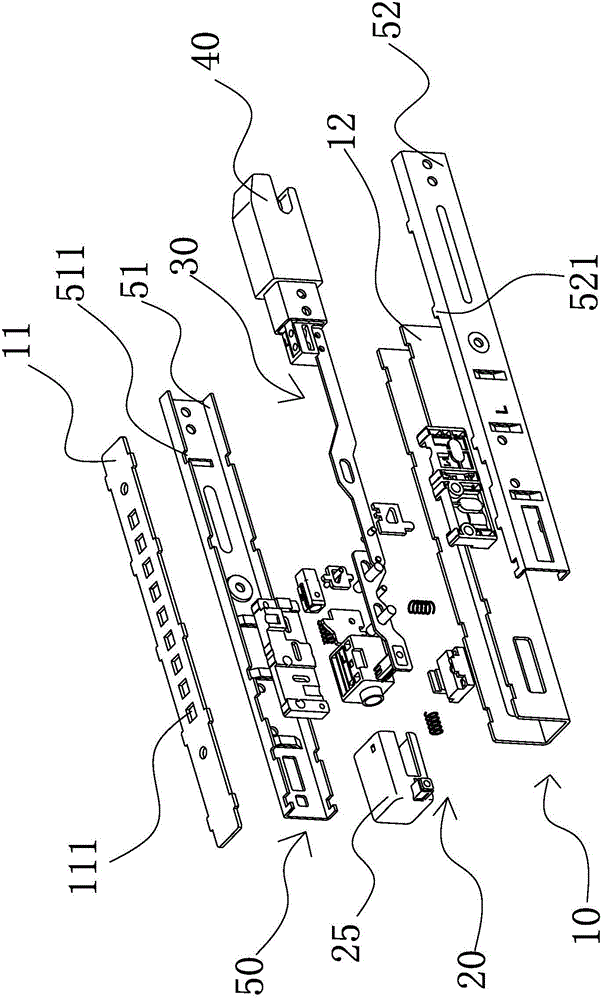

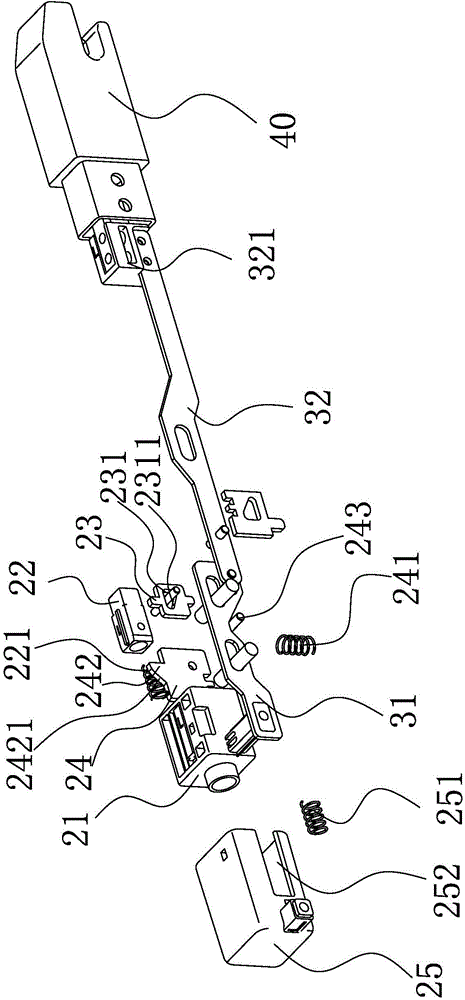

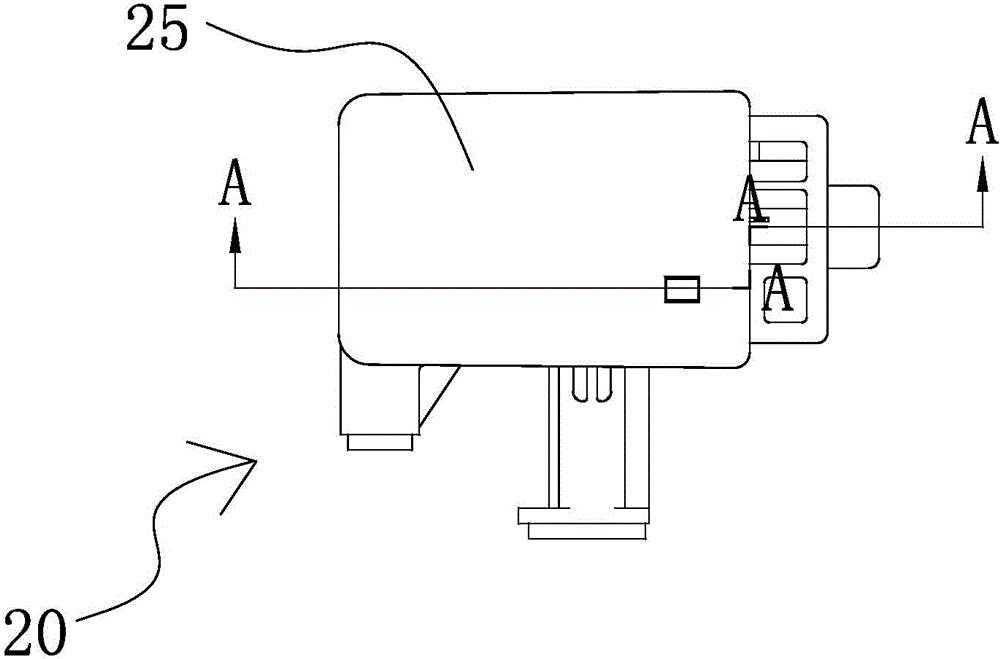

Automobile child safety seat ISOFIX system

A child safety seat and automobile technology, applied in the mechanical field, can solve the problems of short service life of the locking block, safety accidents, easy loosening, etc., and achieve the effects of ensuring stability, improving safety performance, and preventing linkage jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Raw material pretreatment: according to the raw materials used in the locking block in Example 1 in Table 1, preheat to 280°C, keep warm for later use.

[0050] Forming: put the above preheated raw materials into the medium frequency induction furnace, melt them into molten steel at 1000°C, then cast them into steel at 820°C, and obtain the locking block blank through mechanical processing; among them, pouring and mechanical processing The existing pouring process and mechanical processing molding process are adopted.

[0051]Normalizing treatment: The above-mentioned lock block blank is subjected to secondary normalizing treatment, wherein the first normalizing temperature is 890°C, the holding time is 1.0h, and air-cooled to room temperature; the second normalizing temperature is 880°C, The holding time is 1.0h, and air-cooled to room temperature.

[0052] Quenching and tempering treatment: Quenching and tempering the above normalized locking block blank, the quenchi...

Embodiment 2

[0054] Raw material pretreatment: According to the raw materials used in the locking block in Example 2 in Table 1, preheat to 290°C and keep warm for later use.

[0055] Forming: put the above preheated raw materials into the medium frequency induction furnace, melt them into molten steel at 1050°C, then cast them into steel at 840°C, and obtain the locking block blank through machining; among them, pouring and machining The existing pouring process and mechanical processing molding process are adopted.

[0056] Normalizing treatment: The above-mentioned locking block blank is subjected to secondary normalizing treatment, wherein the first normalizing temperature is 920°C, the holding time is 1.0h, and air-cooled to room temperature; the second normalizing temperature is 880°C, The holding time is 1.1h, and the air is cooled to room temperature.

[0057] Quenching and tempering treatment: Quenching and tempering the above normalized locking block blank, the quenching tempera...

Embodiment 3

[0059] Raw material pretreatment: According to the raw materials used in the locking block in Example 3 in Table 1, preheat to 310°C and keep warm for later use.

[0060] Forming: Put the above preheated raw materials into the medium frequency induction furnace, melt them into molten steel at 1100°C, then cast them into steel at 860°C, and obtain the locking block blanks through mechanical processing; among them, pouring and mechanical processing The existing pouring process and mechanical processing molding process are adopted.

[0061] Normalizing treatment: The above-mentioned locking block blank is subjected to secondary normalizing treatment, wherein the first normalizing temperature is 930°C, the holding time is 1.2h, and air-cooled to room temperature; the second normalizing temperature is 900°C, The holding time is 1.2h, and the air is cooled to room temperature.

[0062] Quenching and tempering treatment: Quenching and tempering the above normalized locking block bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com