Sewage treatment system and sewage treatment method

A technology of sewage treatment system and sewage treatment method, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. , to avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

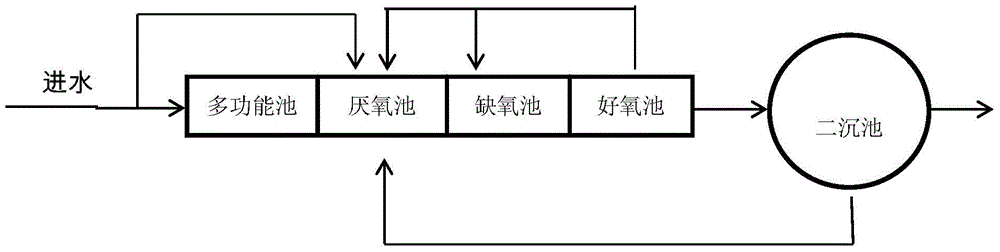

[0068] Under the condition of normal influent water quality, it operates in the improved AAO mode, that is, all the sludge in the secondary sedimentation tank is returned to the anaerobic tank, so that part of the sewage enters the multifunctional tank and part of the sewage enters the anaerobic tank for treatment, and then sequentially Enter the anoxic tank and aerobic tank for treatment, and make part of the effluent from the anaerobic tank return to the anaerobic tank and anoxic tank for anaerobic and denitrification treatment, and the other part of the effluent enters the secondary sedimentation tank to separate the active pollutants. After the mud is used as effluent, the concentration of mixed liquid suspended solids (MLSS) is 3000-5000mg / L, and the concentration of organic solids in the mixed liquid activated sludge (mixed liquid volatile suspended solids, MLVSS) is 1800~2800mg / L, SV30 is 20-40%, dissolved oxygen is 1.5mg / L-4.0mg / L, external reflux ratio is 50%-120%, int...

Embodiment 2

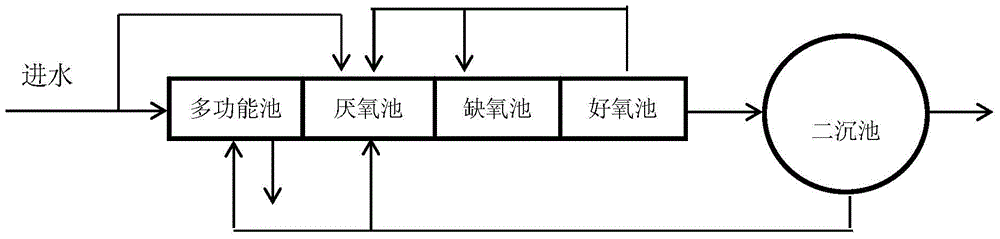

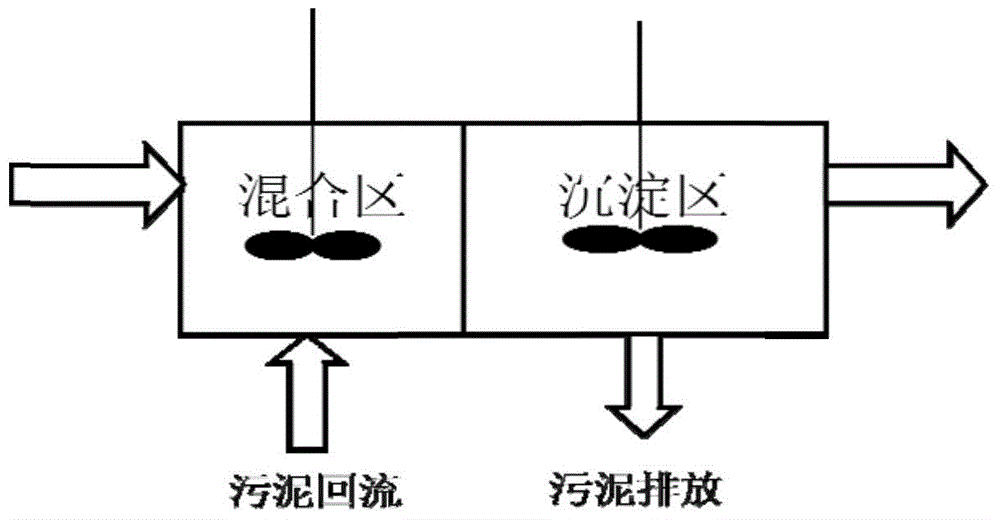

[0070] Under the condition of abnormal influent water quality, part of the returned sludge from the secondary sedimentation tank is returned to the multi-functional tank, and all the sewage influent is introduced into the multi-functional tank for treatment, and then the effluent treated by the multi-functional tank is sequentially entered into the multi-functional tank. Anaerobic pond, anoxic pond and aerobic pond are used for treatment, and the biodegradation of organic matter, nitrogen and phosphorus removal, and other reactions are carried out with the improved AAO process. Wherein the operating parameters of the multifunctional pool are: the residence time in the mixing zone is 30min, and the residence time in the sedimentation zone is 1 hour; the return sludge accounts for 15%-20% of the total return sludge amount; the sludge concentration is between 3000mg / L- 4000mg / L.

[0071] 1) When the influent concentration SS is 512mg / L, the adsorption and removal rate of SS in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com