Afterheat recovery system of drying and setting processor for fabrics, braids and zippers

A waste heat recovery system, drying and shaping technology, applied in the field of dyeing machinery, can solve problems such as waste, achieve the effect of saving energy and improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples, but the implementation and protection of the present invention are not limited thereto.

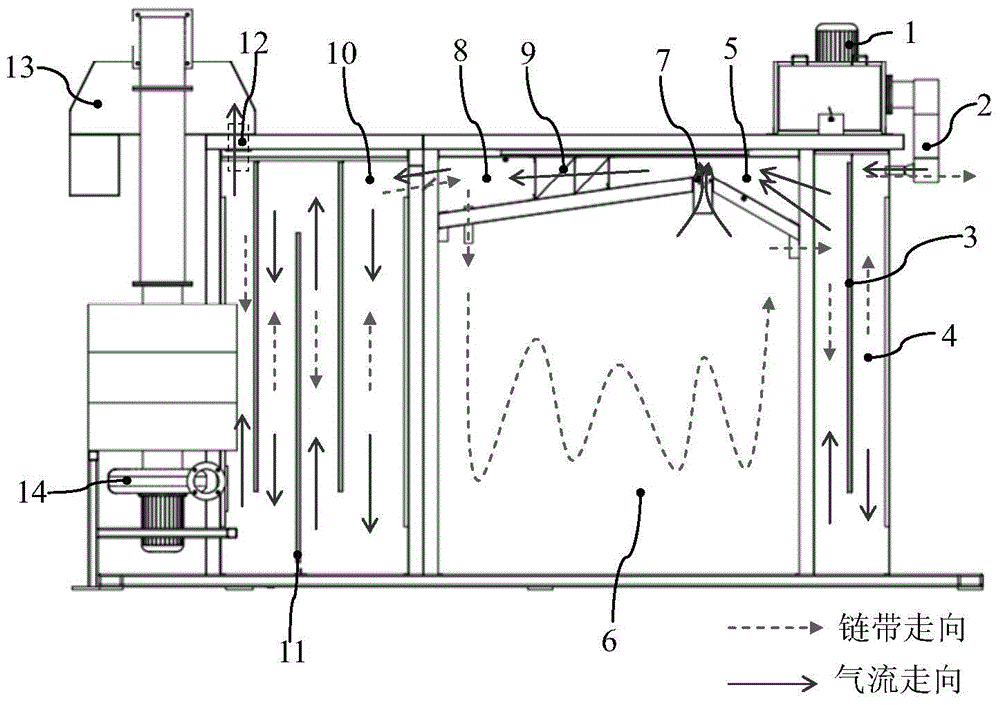

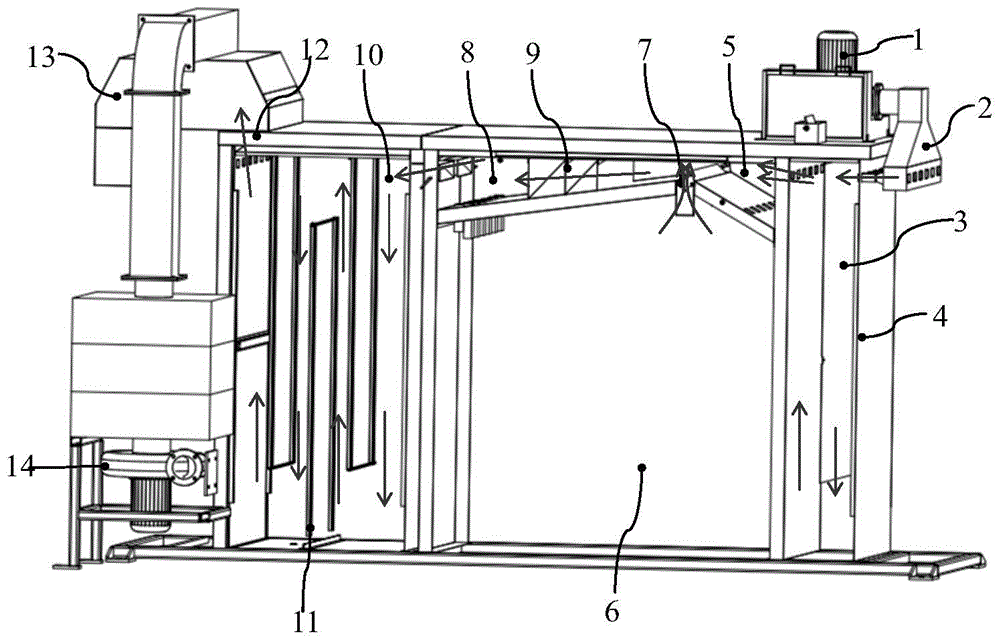

[0019] Such as Figure 1 ~ Figure 2 As shown, a waste heat recovery system for fabric, ribbon, and zipper drying and setting processor, which includes a blower 1, a nozzle 2, a front baffle 3, a cooling box 4, a front suction channel 5, a heating box 6, a heating Box exhaust port 7, rear air flow channel 8, collector plate 9, waste heat tank 10, rear baffle plate 11, exhaust gas outlet 12, exhaust gas collection and purification box 13 and exhaust fan 14; wherein waste heat box 10, heating box 6. The cooling box 4 is arranged sequentially according to the feeding direction of the fabric, webbing, and zipper. The blower 1 communicates with the nozzle 2. The nozzle 2 is located at the outlet of the cooling box 4, that is, at the entrance of the cold air. The front baffle 3 is located in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com