High-pressure industrial heat supply method for thermal power plant

A thermal power plant and industrial technology, applied in the field of unconventional high-pressure industrial heating and thermal power plant industrial heating, can solve the problems of high environmental protection pressure, single function, and increased cost of power plant workshops.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

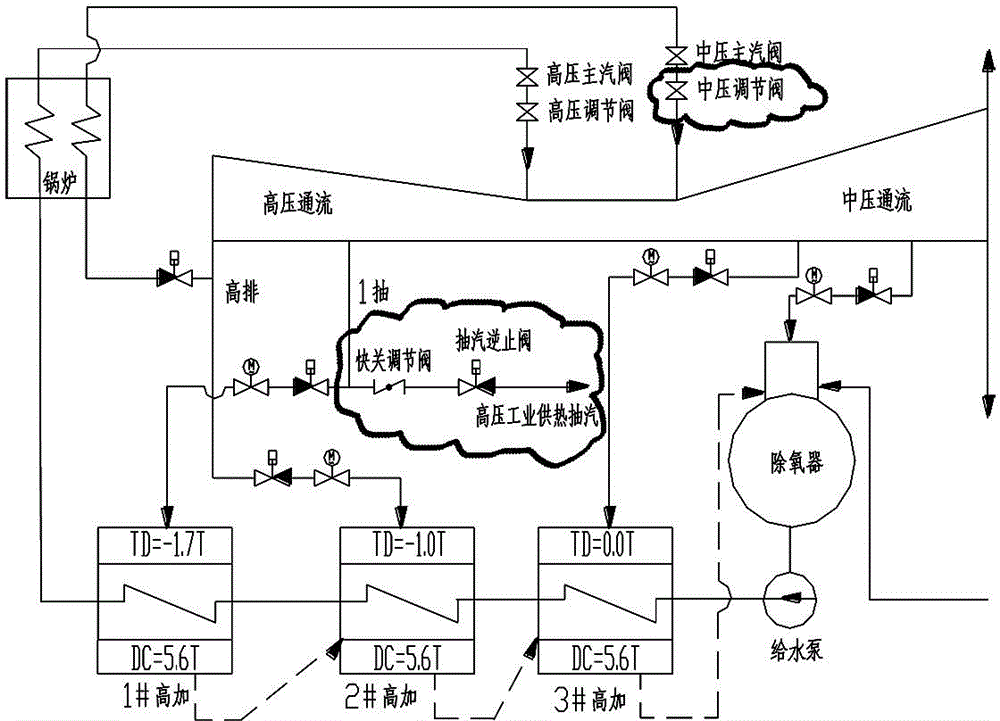

[0014] In order to facilitate the understanding of the present invention, firstly a brief introduction is given to the conventional structure of the large-scale, high-middle pressure cylinder turbogenerator set.

[0015] see figure 1 : The unit is equipped with high-pressure steam extraction, that is, the 1 extraction shown in the figure, the extraction pressure is about 7.5Mpa, and the extracted steam is sent to the high-pressure heater, that is, the 1# high heater shown in the figure, which is used to heat the main feed water of the boiler .

[0016] The high-voltage industrial heat supply method of the thermal power plant is to optimize the design of the above-mentioned high-middle pressure combined-cylinder steam turbine generator set to provide high-voltage industrial heat supply to heat users. The specific measures are:

[0017] - Reduce the high-pressure flow 1 pumping to the high-pressure flow area and the medium-pressure flow area, so that when the rated working cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com