Vibrating material level switch and its vibrating device

A technology of vibration device and material level switch, which is applied to measuring devices, lubrication indicating devices, engine components, etc., can solve the problems of changes in vibration characteristics, affecting vibration characteristics, and lack of penetration, so as to avoid changes in mechanical properties and avoid vibration. Changes in characteristics, effects of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] This embodiment provides a vibrating material level switch.

[0056] The vibration type material level switch includes a control circuit and a vibration device.

[0057] The control circuit adopts the existing control circuit, and this technology is already very mature, so it is not shown in the drawings of this application, and it is not explained in detail at the same time.

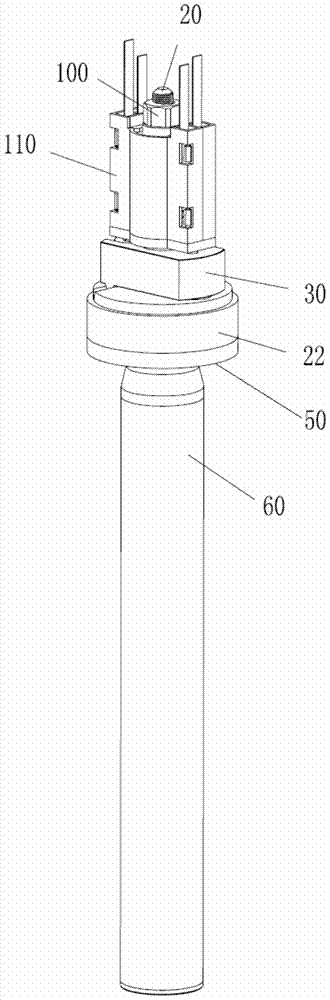

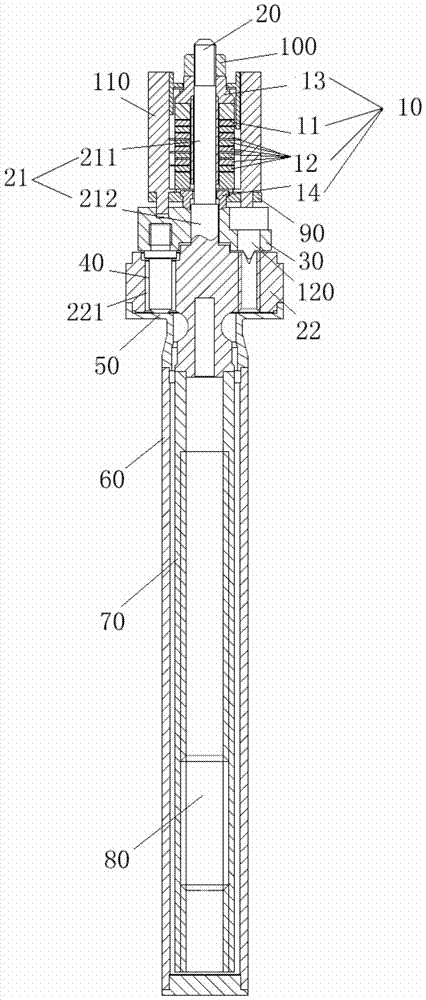

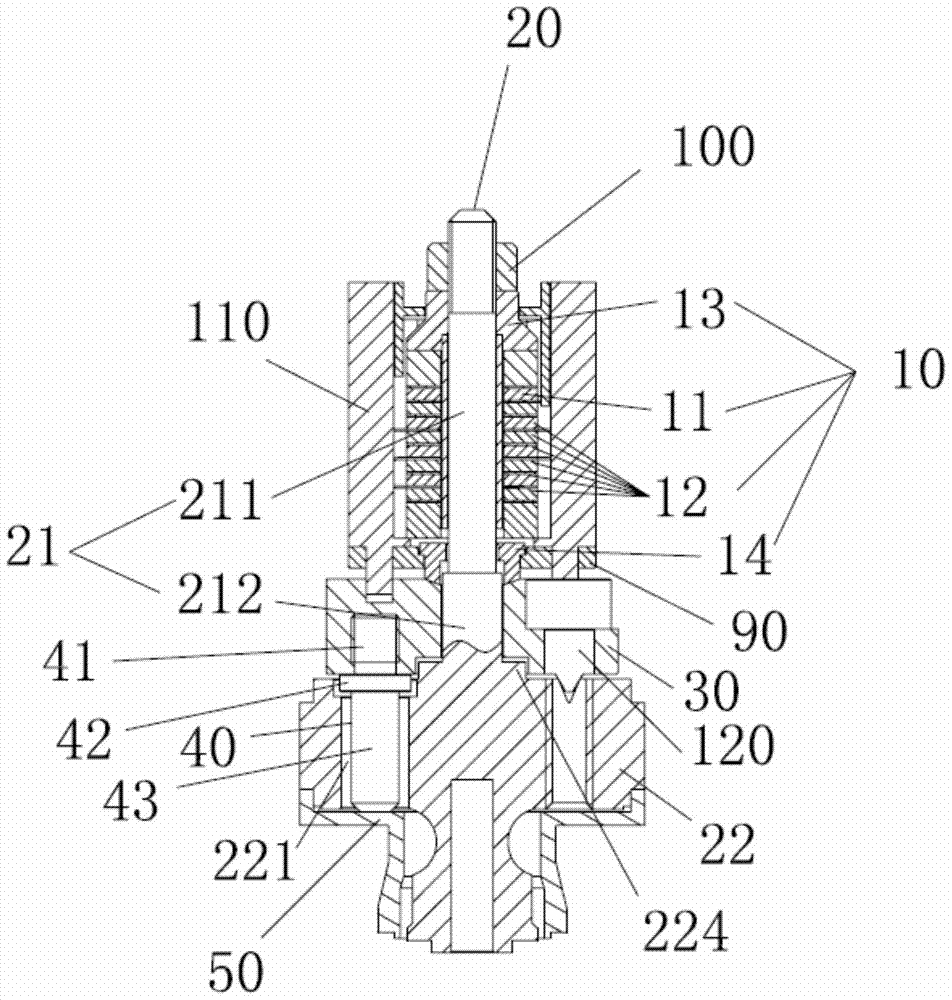

[0058] Please continue to refer figure 1 and 2 , the vibrating device includes a piezoelectric assembly 10 , a tension rod 20 , a bridging block 30 , a pressing piece 40 , a diaphragm 50 , a vibrating outer tube 60 and a vibrating inner tube 70 .

[0059] Please refer to Figure 2-4 , the tension rod 20 includes a rod-shaped mounting body 21 and a transition body 22 whose radial dimension is larger than that of the mounting body 21 . The transition body 22 can be a disc-like structure, the installation body 21 is located above the transition body 22, and the two are of an integrated structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com