FPSO (Floating Production Storage and Offloading) type automatic vacuum sweeping control method

A control method and vacuum technology, applied in the direction of non-electric variable control, control/regulation system, simultaneous control of multiple variables, etc., can solve the problems of large platform shaking and poor stability, and achieve improved efficiency, good reliability and accuracy , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

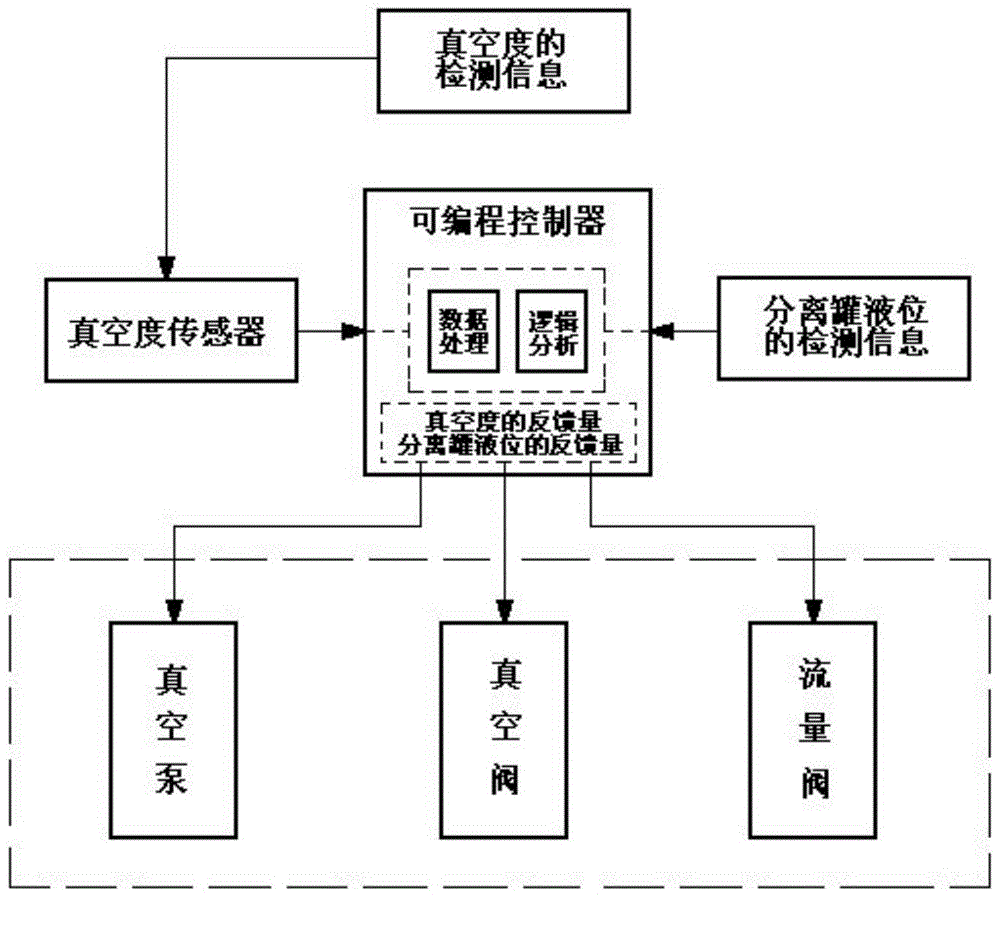

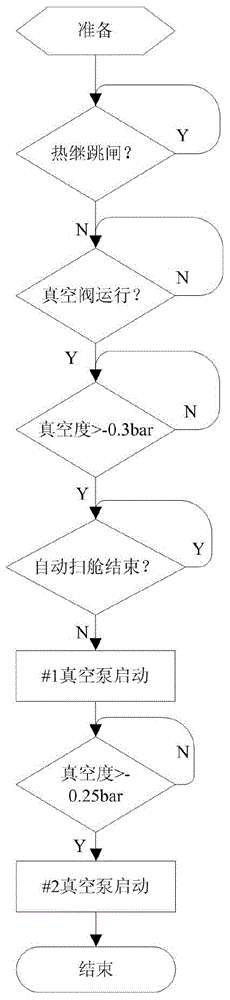

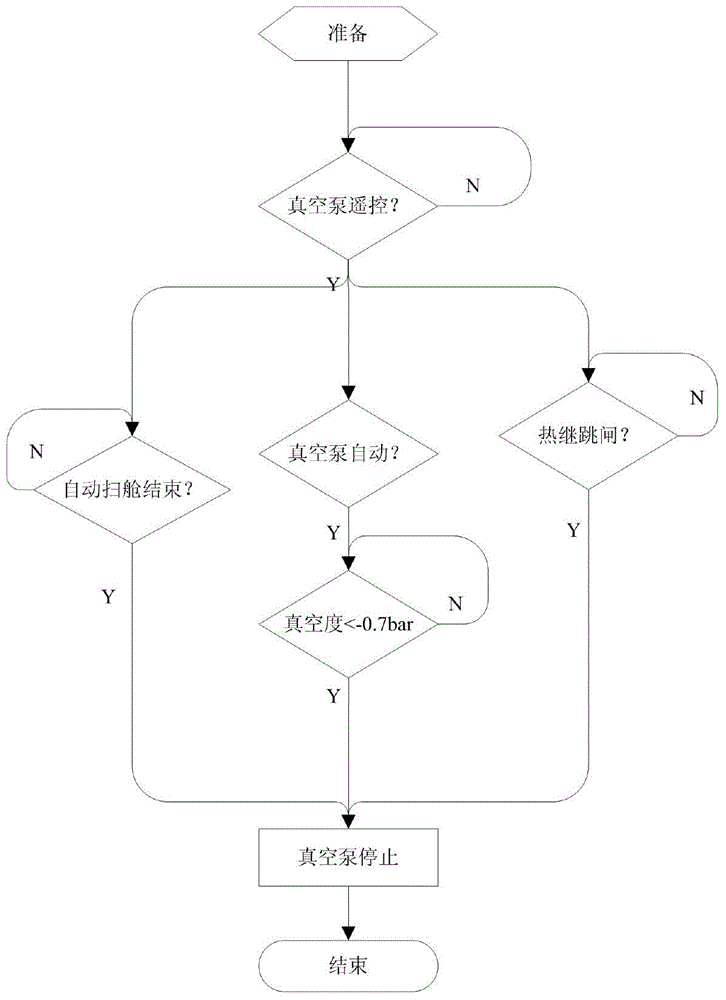

[0028] Such as figure 1 As shown, the present invention collects the detection information of the vacuum degree and the liquid level of the separation tank for controlling the vacuum pump, the vacuum valve and the flow valve. The present invention adopts a vacuum degree sensor, collects the detection information of the vacuum degree through the vacuum degree sensor, and sends the collected detection information of the vacuum degree and the detection information of the liquid level of the separation tank as the feedback amount of the vacuum degree and the liquid level of the separation tank to the Through the programmable controller, the closed-loop control algorithm is used for data processing and logic analysis, and according to the functional relationship between the vacuum degree and the liquid level of the separation tank, the accurate control of vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com