A kind of manufacturing method of thermoplastic composite polymer bonded magnet

A composite polymer and manufacturing method technology, applied in the field of high-magnetic rare earth magnetic powder and its production process, can solve the problems of product quality decline, affecting the fluidity of the thermoplastic process, magnet microscopic cavities, etc., and achieve the effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings .

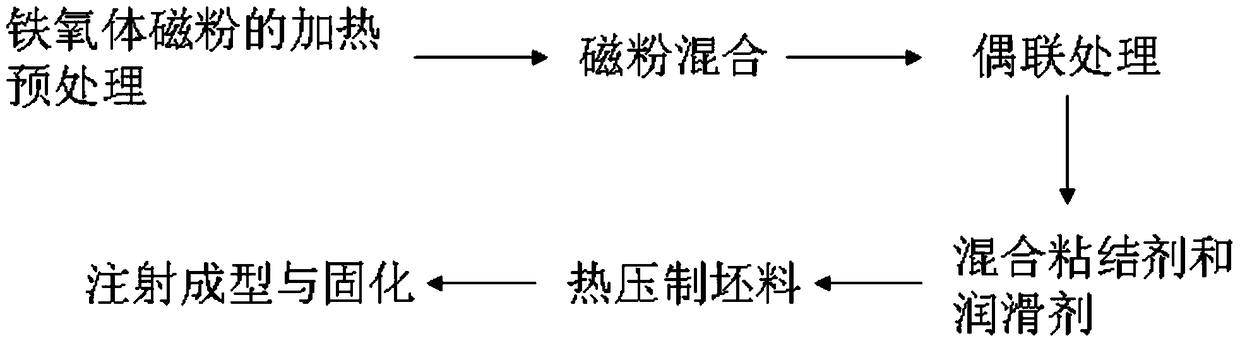

[0023] like figure 1 As shown, the present invention provides a method for manufacturing a thermoplastic composite polymer bonded magnet, and the detailed steps of the method are described below.

[0024] First, take NdFeB rare earth magnetic powder and ferrite magnetic powder and mix evenly, so that the weight ratio of iron boron rare earth magnetic powder and ferrite magnetic powder is 3:2. Since the particle size of untreated ferrite magnetic powder is several microns, and the particle size of NdFeB rare earth magnetic powder is more than 50 microns, in order to reduce the particle size difference between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com