Device and method for detecting temperature control function of sodium-sulfur battery management unit

A management unit, sodium-sulfur battery technology, applied in the direction of electrical components, secondary batteries, secondary battery repair/maintenance, etc., can solve problems such as many supporting equipment, poor operability, and danger of sodium-sulfur battery module temperature rise, and achieve accurate Judgmental, easy to observe, simple structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

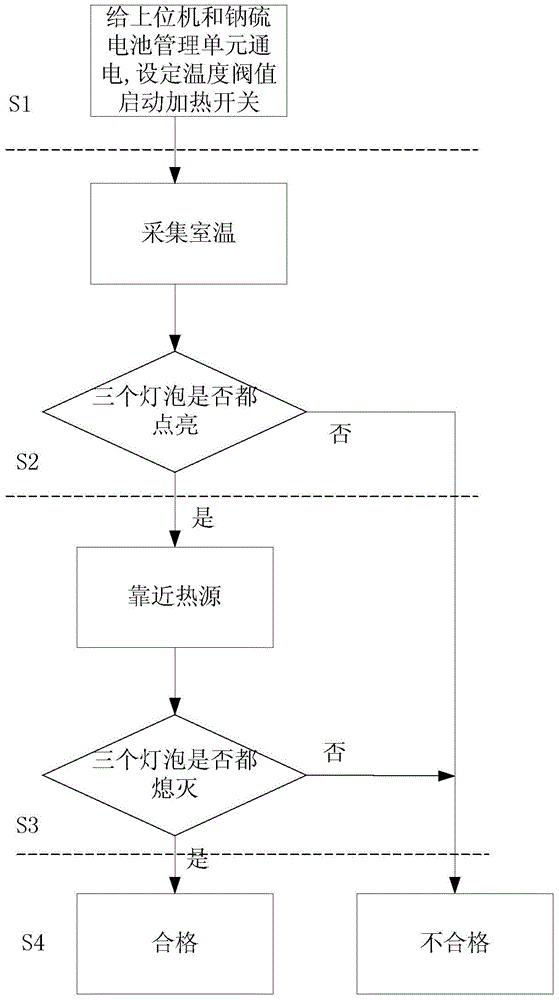

[0021] The present invention will be further described below in conjunction with accompanying drawing.

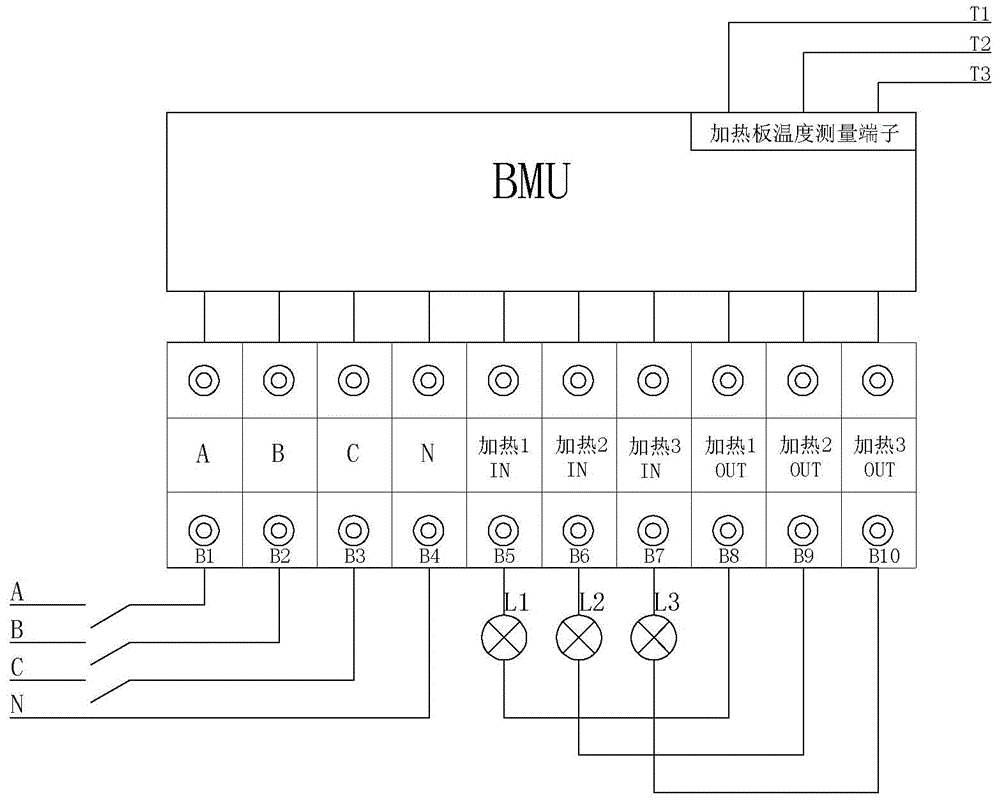

[0022] see figure 1 , the sodium-sulfur battery management unit includes: the input terminals B5, B6, and B7 of the heating circuits of the heating plates of the three incubators corresponding to each other, the output terminals B8, B9, and B10 of the heating circuits of the heating plates of the three incubating boxes, and three heating plates Temperature measurement terminal. B1-B4 are the power supply ports of the BMU heating circuit. The temperature control function detection device of the sodium-sulfur battery management unit of the present invention includes a host computer (not shown in the figure), three light bulbs L1, L2, L3 and three K-type thermocouples T1, T2, T3, wherein,

[0023] Three light bulbs L1, L2, L3 are respectively connected between the input terminals B5, B6, B7 of the heating circuits of the heating plates of the three incubators and the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com