Stator-split alternating-current servo motor

A technology for AC servo motors and stators, which is applied to electrical components, electromechanical devices, and electric components. It can solve the problems of increasing the rate of stator embedding slots, reducing motor copper consumption, and low material utilization, so as to save raw materials and improve output. power ratio, improve process reliability and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

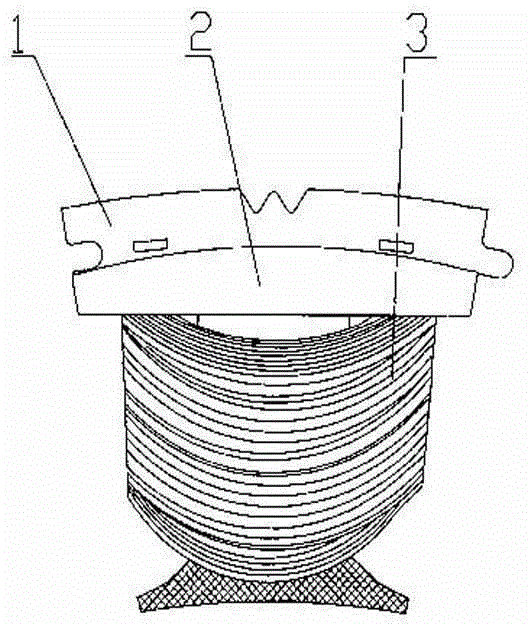

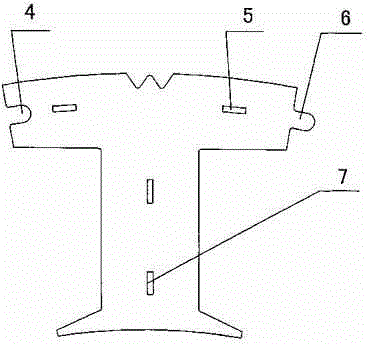

[0013] Attached below Figure 1-4 Further explanation of this stator split AC servo motor:

[0014] refer to Figure 1-2

[0015] The single split stator core 1 is in the shape of a "worker". The two ends of the yoke of the stator core 1 are provided with protrusions 6 at one end, and the other end is provided with a groove 4 that is compatible with the protrusions 6. The middle part is partially toothed and multi-piece The stator core 1 is stacked together, the winding 3 is directly wound on the teeth of the stator core 1, two nails 5 are set on the yoke of the stator core 1, and two nails 7 are set on the teeth of the stator core 1.

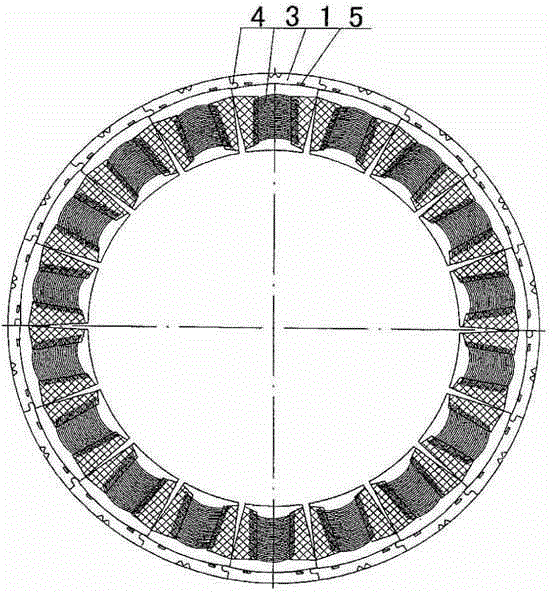

[0016] refer to image 3 :

[0017] According to design requirements, the number of multiple sets of stator slots is a multiple of 3. Preferably 9 slots, 15 slots, 18 slots or 27 slots. The grooves designed in this embodiment are tens of 18 grooves. The split stator core 1 is combined and assembled as a whole through a tightening device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com