Imitation leather fabric and method of producing same

A fabric and leather technology, applied in the field of imitation leather fabrics and fabrics, can solve the problems of non-uniform deformation, low stability, unstable surface of imitation leather, etc., and achieve the effect of good hand feeling and comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

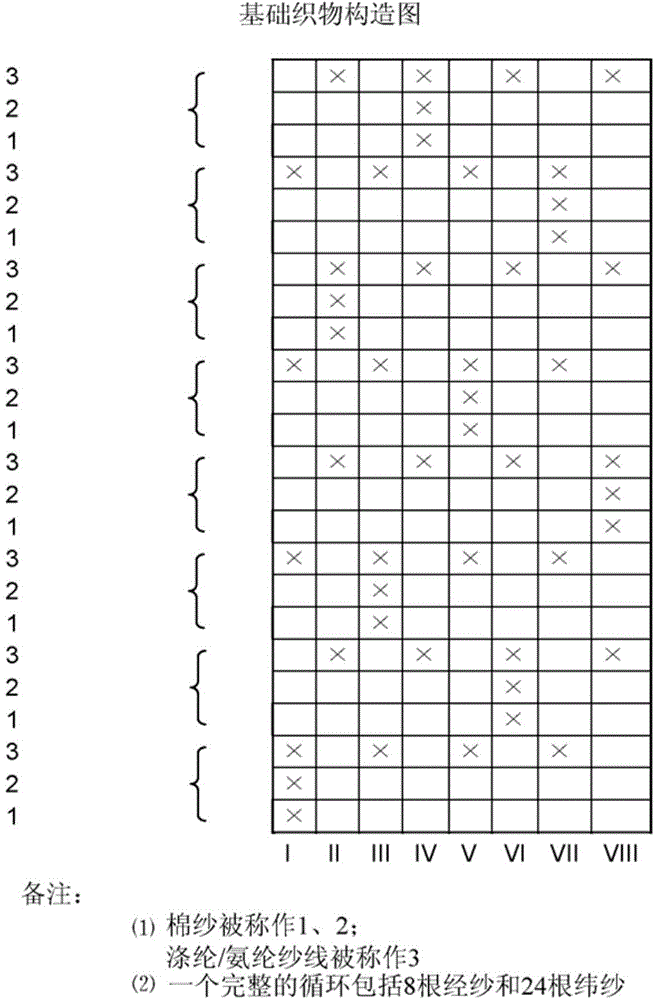

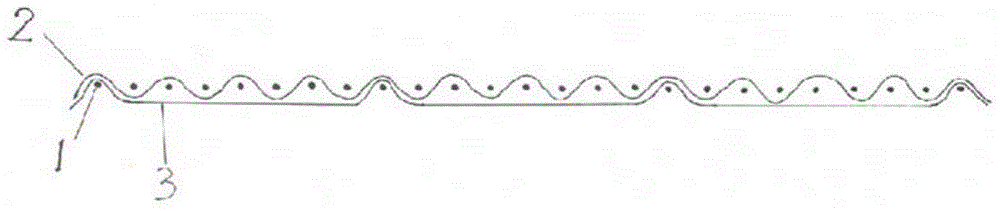

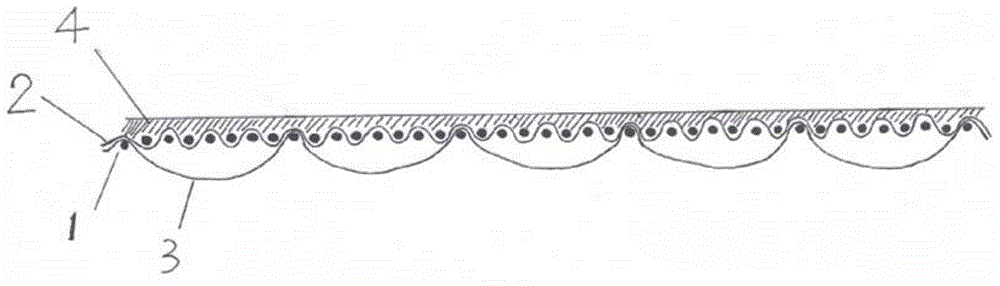

[0098] will now refer to Figures 1 to 11 A preferred embodiment of the present invention will be described which includes a leather-like fabric and a method for its production which involves coating a double layer base fabric with a polyurethane resin.

[0099] The base fabric includes a first fabric layer that forms a conventional twill or plain weave (eg, 1 / 1 plain, 2 / 1 twill, 3 / 1 twill, etc.). In this embodiment, the first set of fiber components comprises warp yarns of the first fabric layer and the second set of fiber components comprises weft yarns of the first fabric layer. In this configuration, the weft and warp fiber components are relatively dense and tightly woven together such that the weave is configured to provide stability to the leather-like fabric when external forces are applied to the leather-like fabric.

[0100] The first group of fiber components is made of cotton material with a yarn count in the range of about 10-60 Ne. The second group of fiber co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com