Recovery and storage system

A material storage and pipe system technology, used in solid separation, separation of solids from solids by air flow, separation of dispersed particles, etc., can solve the problems of increasing the number of equipment, low work efficiency, waste of ultra-light materials, etc. The number of equipment, low work efficiency, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

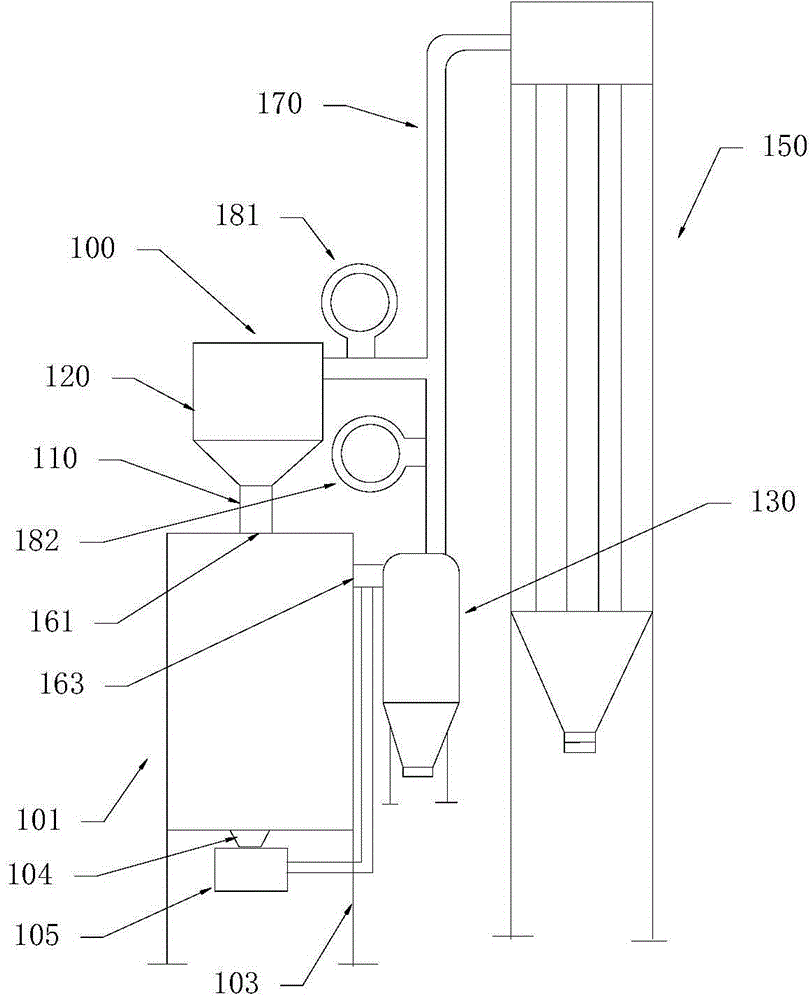

[0043] Embodiment 1, with reference to figure 1 , figure 1 It is a structural schematic diagram of the first embodiment of the recovery and storage system of the present invention.

[0044] The recycling storage system includes a multi-pipe system 100 , a bag filter 150 and a silo 101 .

[0045] The silo 101 is arranged on a support 103 standing on the ground. The multi-tube system 100 includes a first multi-tube dust collector 120 and a second multi-tube dust collector 130, the silo 101 includes a first feed port 161 and a first discharge port 163, and the first multi-tube dust collector The discharge port at the lower end of the device 120 is connected to the first feed port 161 through the feed pipe 110, the exhaust port of the first multi-pipe dust collector 120 is connected to the bag filter 150 through a pipeline 170, and the second multi-pipe dust collector 150 The air inlet of the tube dust collector 130 is connected to the first discharge port 163 , and the exhaust...

Embodiment 2

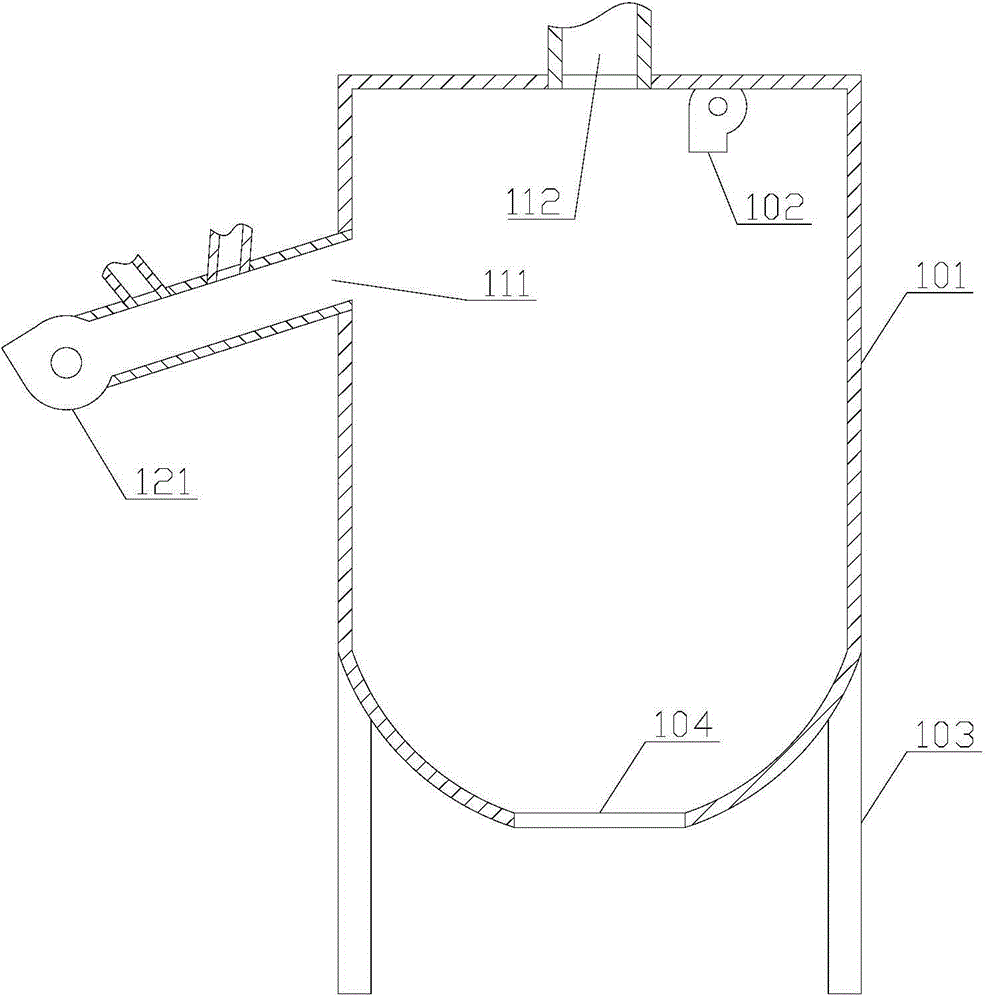

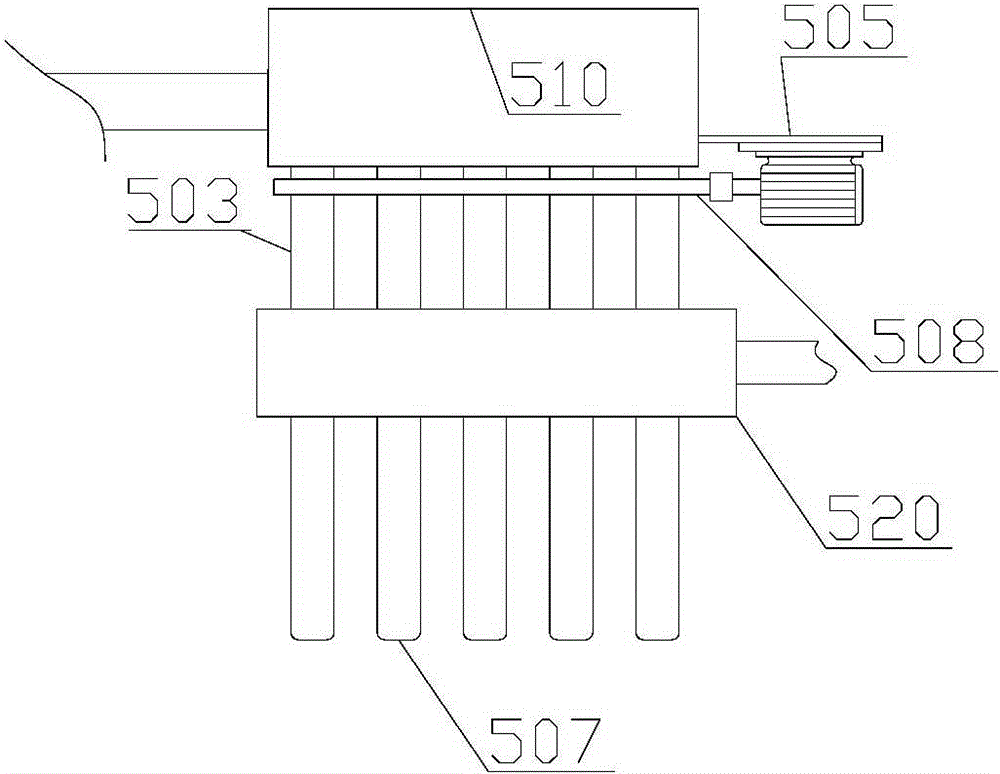

[0052] Embodiment 2, refer to Figure 1 to Figure 5 , figure 2 It is a schematic structural view of the silo in the second embodiment of the recovery and storage system of the present invention, image 3 It is a schematic structural view of the bag filter in the second embodiment of the recycling storage system of the present invention, Figure 4 It is a structural schematic diagram of the feed structure in the second embodiment of the recovery and storage system of the present invention, Figure 5 It is a structural schematic diagram of the ventilation device in the second embodiment of the recovery and storage system of the present invention.

[0053] The recovery and storage system of this embodiment has the same basic structure, principle and technical effect as that of Embodiment 1. For a brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in Embodiment 1.

[0054] The recovery and storage system obtained t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com