Method for preparing sodium sulfide by processing hydrogen sulfide acid gas and special device thereof

A special device, sodium sulfide technology, applied in the direction of alkali metal sulfide/polysulfide, etc., can solve the problems of large equipment, poor environment, long process route, etc., and achieve small device, flexible operation, and good operating environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

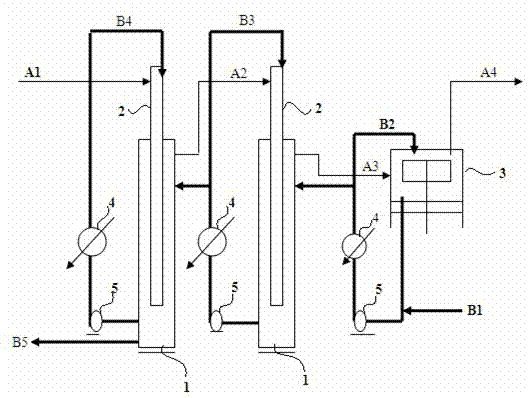

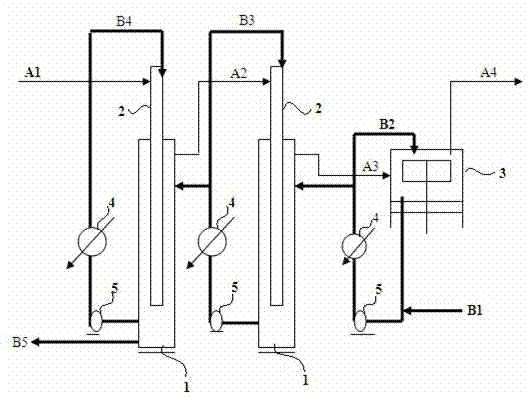

Image

Examples

Embodiment 1

[0018] The process of the present invention is suitable for the treatment of high-concentration acid gas, and is especially suitable for combining with the desulfurization process of circulating absorption method, such as AS desulfurization process, vacuum potassium carbonate desulfurization process, alcohol amine desulfurization process and the like. It is also suitable for the purification of tail gas from sulfuric acid manufacturing plants, and the desulfurization of refinery gas and petroleum liquefied gas produced in various processes of petroleum refining in the petrochemical industry. Produces gas purification treatment with high concentration of hydrogen sulfide. The process of the present invention can be used as a concentrated hydrogen sulfide or sulfur dioxide gas purification process and be connected with the above-mentioned desulfurization process.

[0019] Utilize double hypergravity of cyclone of the present invention to process hydrogen sulfide sour gas to prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com