Follow-up turning device and method of thin-wall curved generatrix revolving part

A part-following, curved generatrix technology, applied in turning equipment, positioning devices, clamping devices, etc., can solve problems such as low roundness requirements, high requirements for part wall thickness accuracy, and inability to accurately repeat the profile of plastic-formed parts. Good wall thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

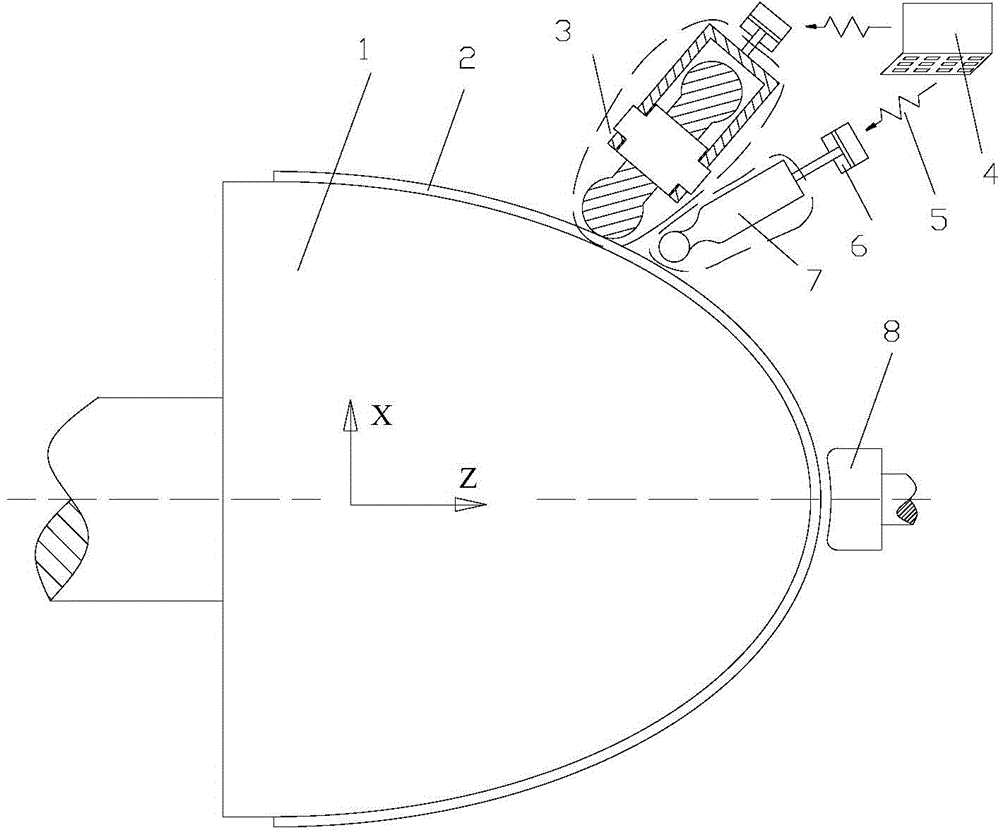

[0025] Such as figure 1 As shown, a thin-wall curved generatrix turning body part follows the turning device, including a molded tire 1, a pressing structure 3, a numerical control system 4 and a turning structure 7, wherein the part 2 to be processed is placed in a position similar to the arc of the part 2 to be processed on the molded tire 1, and is pressed and fixed by the tail top 8 at the far right; the pressing structure 3 and the turning structure 7 are pressed together on the surface of the part 2 to be processed, and the pressing structure 3 and the turning structure 7 are controlled by the numerical control system 4 The movement trajectory of the NC system 4 sends the NC signal 5 to control the servo system 6 connected with the turning structure 7, and drives the turning structure 7 to process the parts to be processed; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com