Observing system used in machining process and application method thereof

An observation system and mechanical processing technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve high-risk problems, achieve simple disassembly, save observation time, and be easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

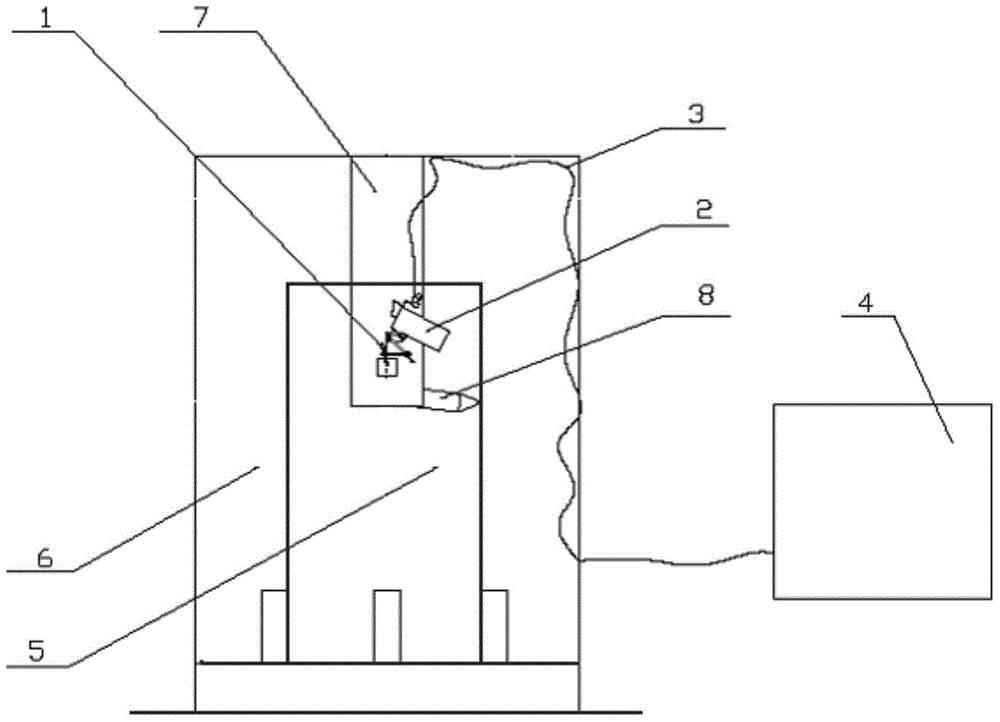

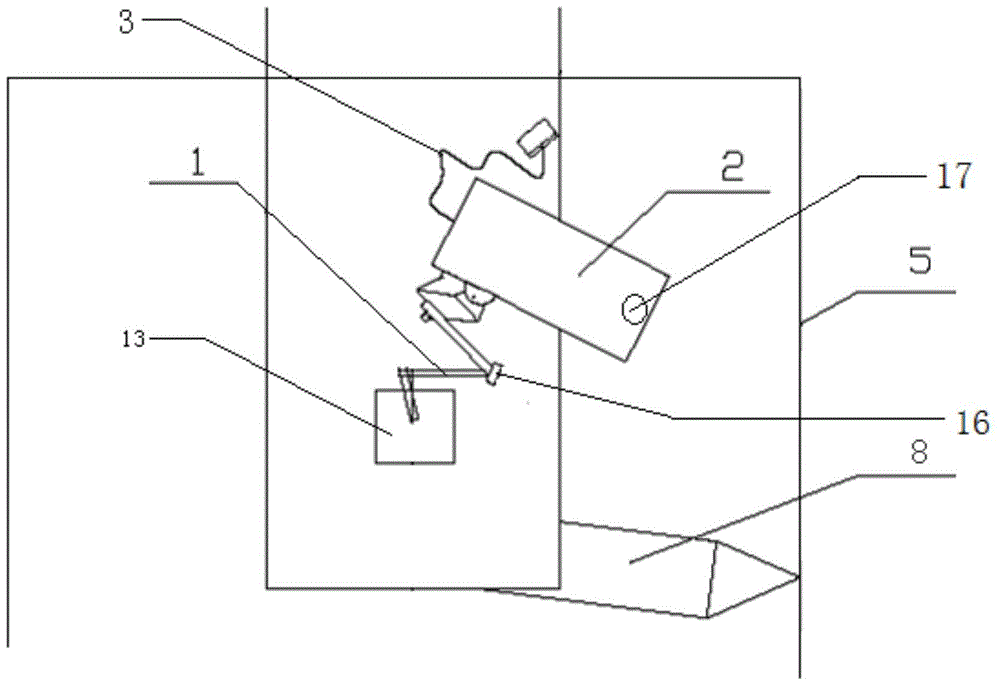

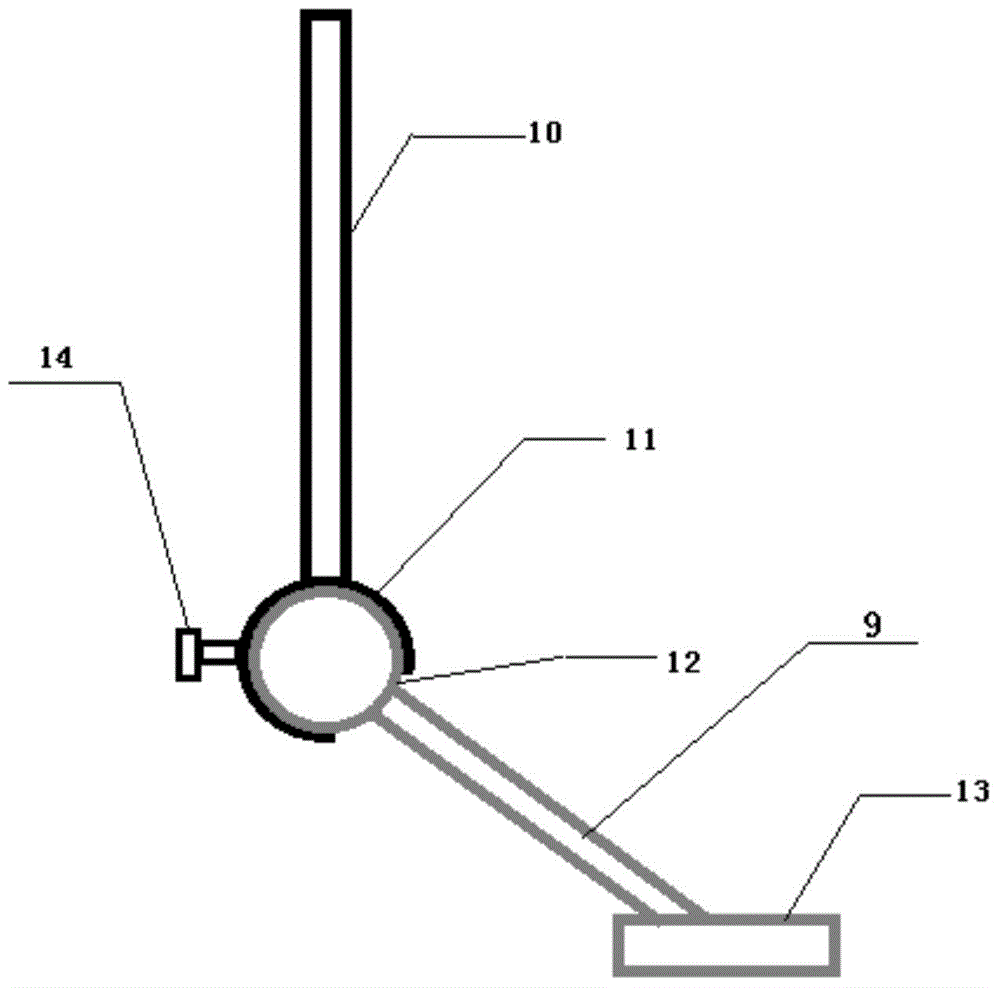

[0033] A kind of observation system that is used in machining process, comprises universal rod 1, camera 2 and display 4; Described camera 2 is fixedly arranged on lathe tool rest 7 by universal rod 1; Described camera 2 and display 4 Connected by wireless transmission; the universal rod 1 includes a first connecting rod 9 with a spherical head 12 and a second connecting rod 10 with a spherical cavity 11, and the first connecting rod 9 and the second connecting rod 10 pass through the spherical head 12 is connected with the spherical joint 16 formed by cooperating with the spherical cavity 11, and a bolt top screw 14 is provided through the spherical cavity 11, and the bolt top screw 14 is threadedly connected with the spherical cavity 11, and the number of the spherical joints 16 is 2 Two ball joints 16 are connected in series.

Embodiment 2

[0035] An observation system used in the machining process, the structure is as described in Embodiment 1, the difference is that: the top of the universal rod 1 is provided with a motor, and the camera 2 is fixedly arranged on the output shaft of the motor; The camera 2 is provided with an infrared receiving device 17, and the infrared receiving device 17 controls the rotation of the motor; the tool generates heat on the processing part of the workpiece, and the infrared receiving device 17 recognizes the heat of the processing part to realize precise positioning of the processing part , so as to control the rotation of the motor, so that the camera 2 can be further precisely aimed at the processing part.

Embodiment 3

[0037] An observation system used in the machining process, the structure is as described in Embodiment 1, the difference is that: the universal rod 1 is adsorbed and fixed on the lathe tool holder 7 through a magnetic magnetic base 13, A magnetic groove corresponding to the size and shape of the magnetic base 13 is provided on the lathe tool holder 7; the magnetic base 13 is embedded in the magnetic groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com