Multifunctional marking machine

A marking machine, multi-functional technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of poor control of engraving degree, no marking effect, lack and other problems, achieve high degree of automation, fabric Low strength loss and versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

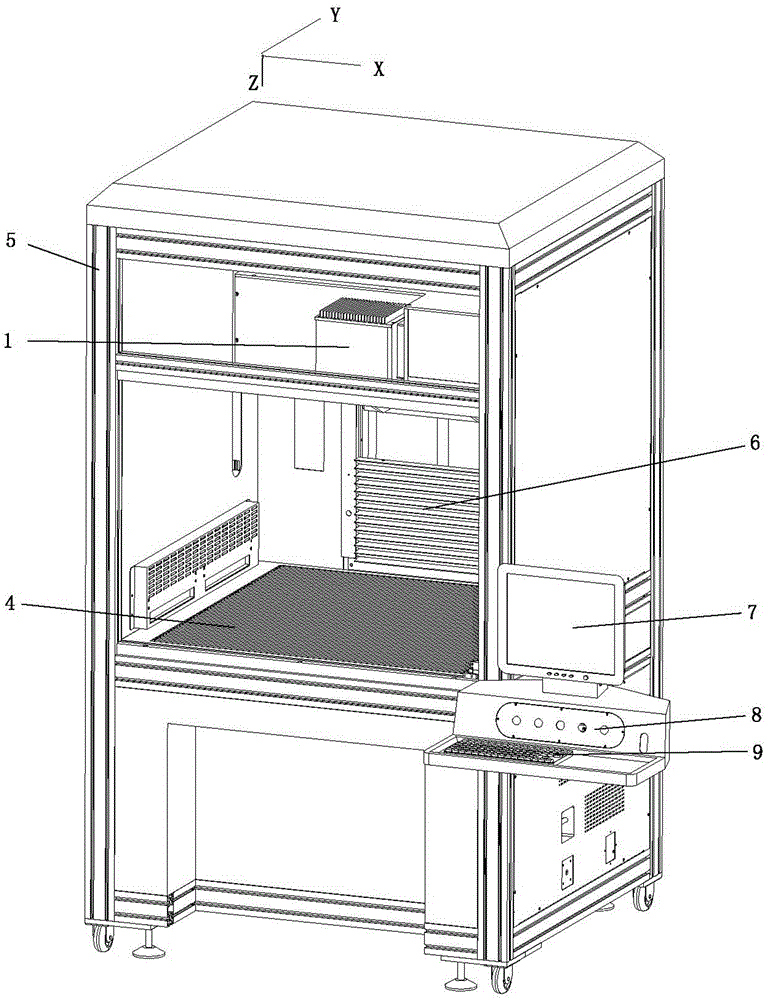

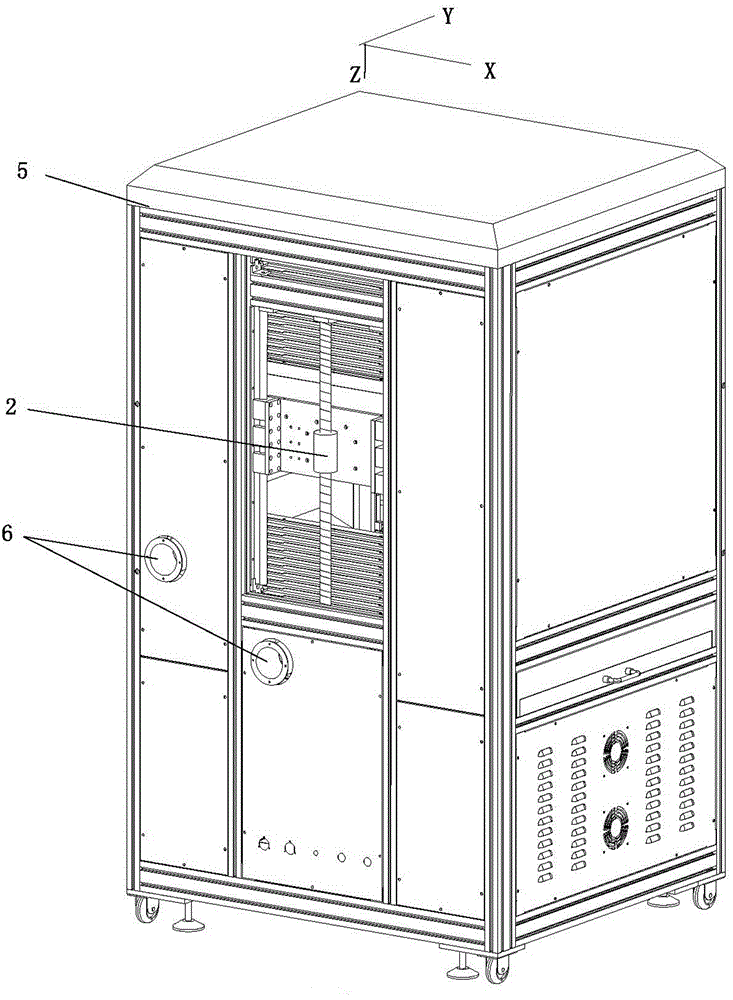

[0038] Such as Figures 1 to 5 As shown, a multifunctional marking machine includes an optical path assembly 1, a lifting device 2, a worktable 4, a preview device and a control system. The optical path assembly 1 is installed on the lifting device 2, and the workpiece to be processed is placed on the working table. On the table 4, the optical path assembly 1 is located above the work table 4, and the preview device can preview the marking position and pattern of the laser on the workpiece to be processed.

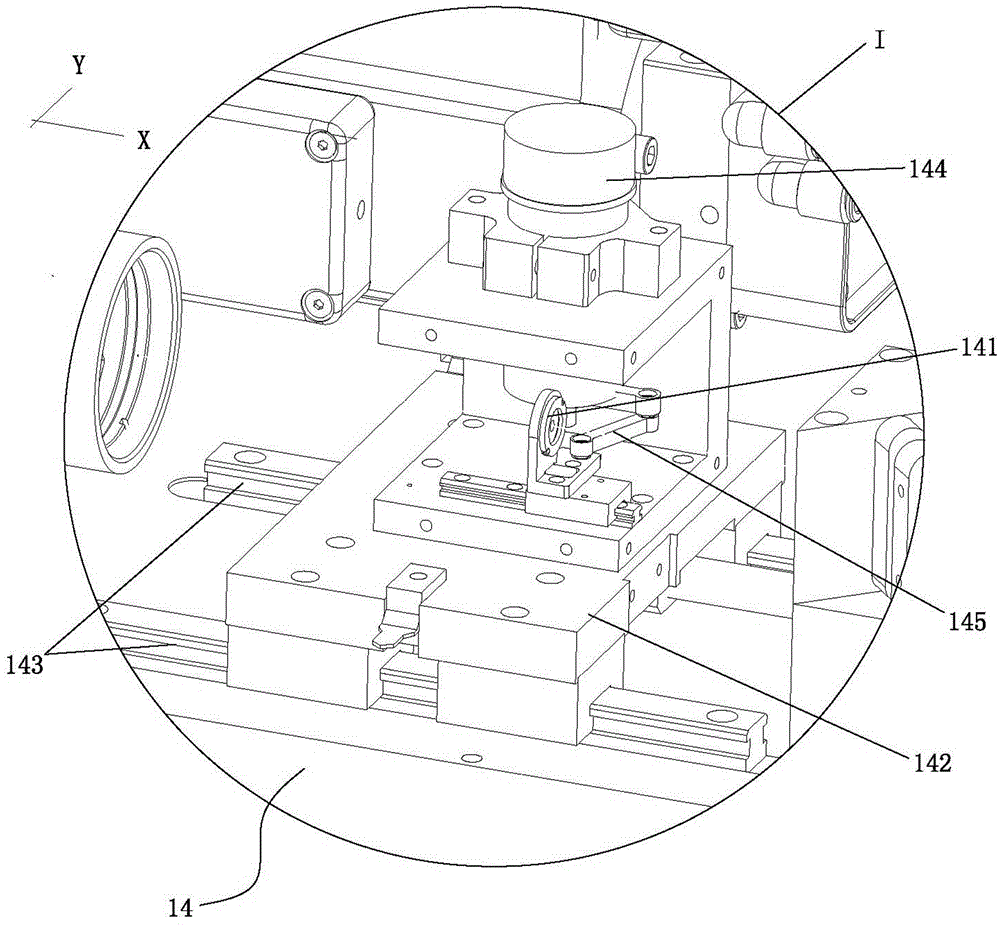

[0039] The optical path assembly 1 includes a laser generator 12, an optical path control device 13, a dynamic focusing device 14, and a vibrating mirror device 15 arranged on a substrate 11. The laser beam generated by the laser generator 12 is projected to the dynamic focusing device 14 through the optical path control device 13 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com